Frame-shear piezoelectric friction damping device

A friction damping, frame structure technology, applied in building components, building structure, earthquake-proof and other directions, can solve the problem that doors and windows cannot be installed in the installation position, affecting the building shape and use function, etc., and achieves easy disassembly, replacement and installation, and simple structure. , the effect of good energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

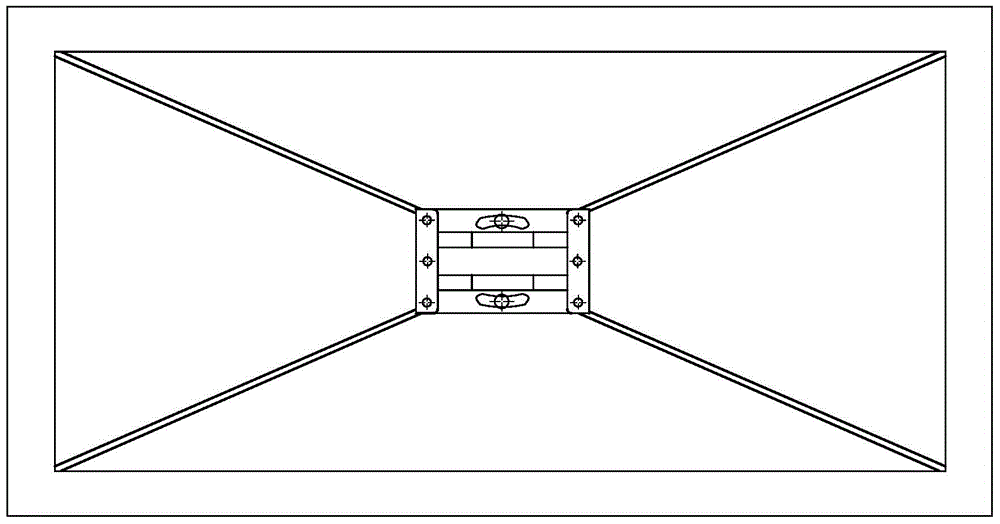

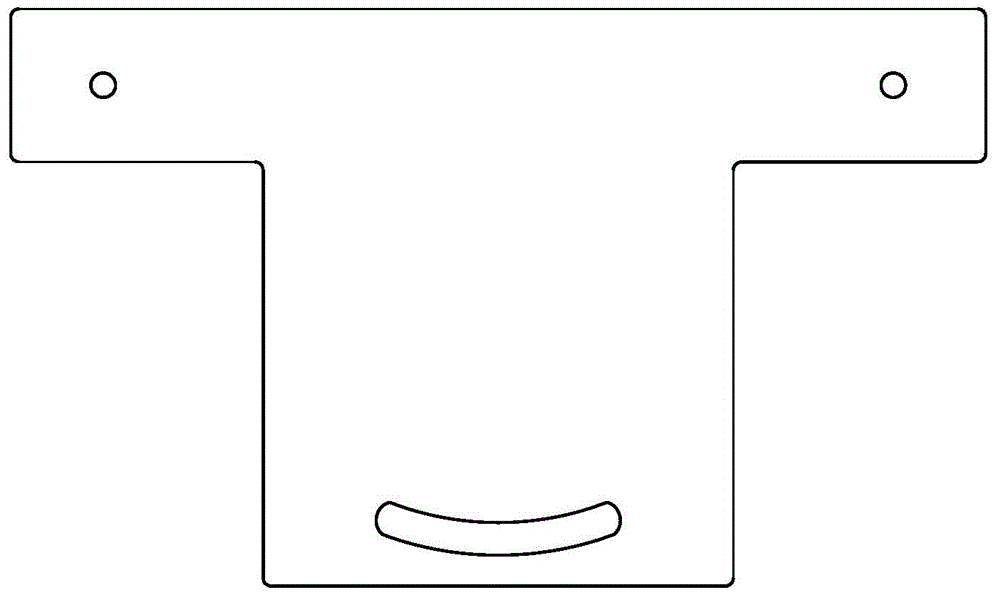

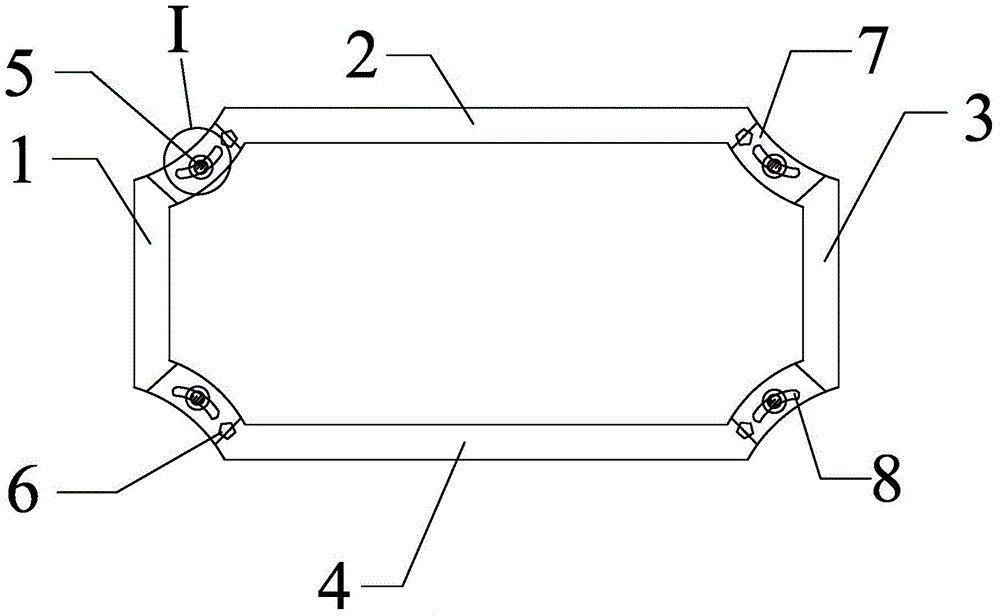

[0022] like Figure 3-Figure 5 As shown, a frame structure shear type piezoelectric friction damping device includes a frame and four friction damping devices 5, the frame is a rectangular frame structure, including four steel plates connected end to end, and the four steel plates include a steel plate 1. Steel plate two 2, steel plate three 3 and steel plate four 4, the two ends of the steel plates are respectively provided with connection parts 7, the connection part 7 is provided with a through groove 8, and the connection part 7 is in the direction of the frame Protruding arc shape, the through groove 8 is in the shape of an arc protruding into the frame, the through groove 8 is consistent with the curvature of the connecting part 7, and the connection between two adjacent steel plates Corresponding to the slot 8 on the part 7 and connected by the friction damping device 5, the friction damping device 5 can slide along the slot 8, the friction damping device 5 includes a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com