Multifunctional lightweight concrete curtain wall connecting structure

A lightweight concrete and connection structure technology, applied to walls, building components, building structures, etc., can solve the problems of difficult positioning, large application limitations, and limited load-bearing of pendants, so as to eliminate application limitations and improve installation efficiency , Improve the effect of bearing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

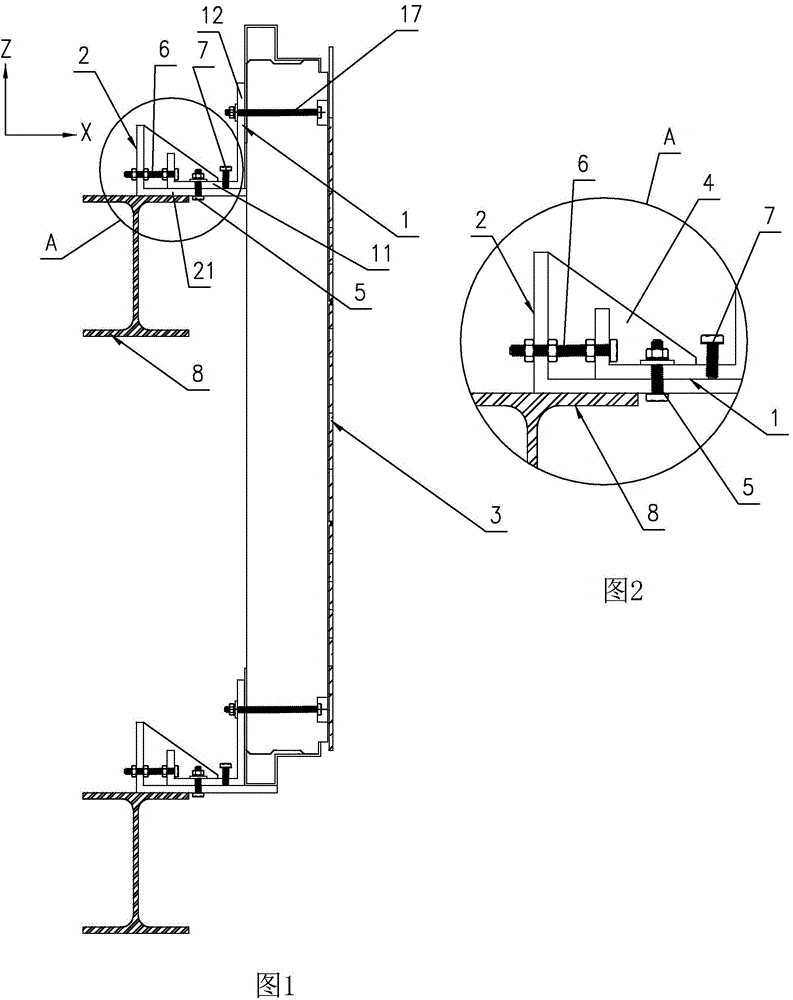

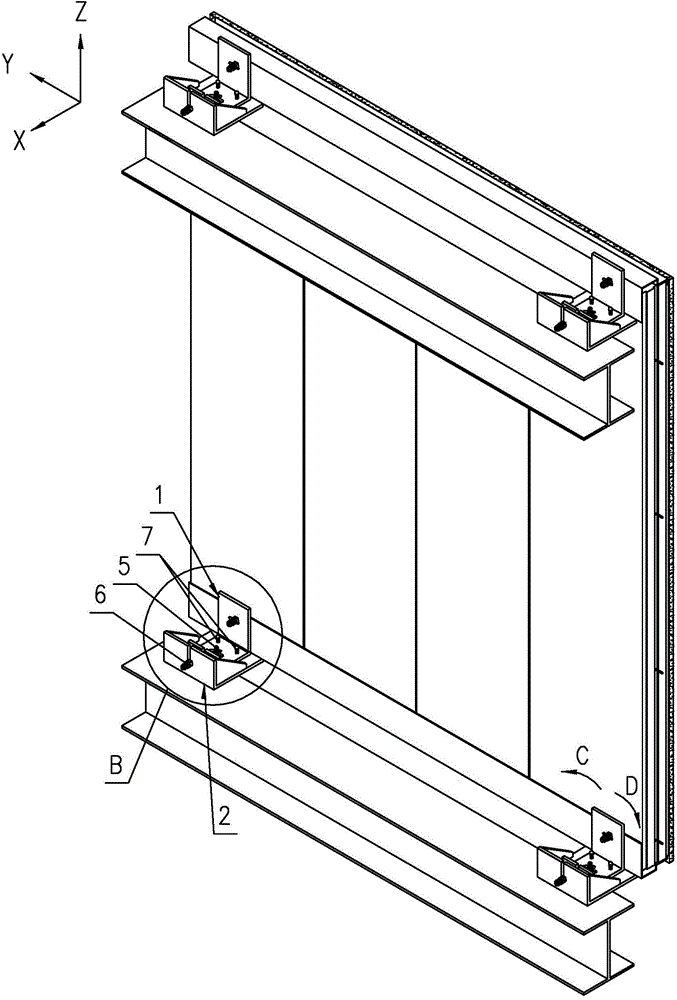

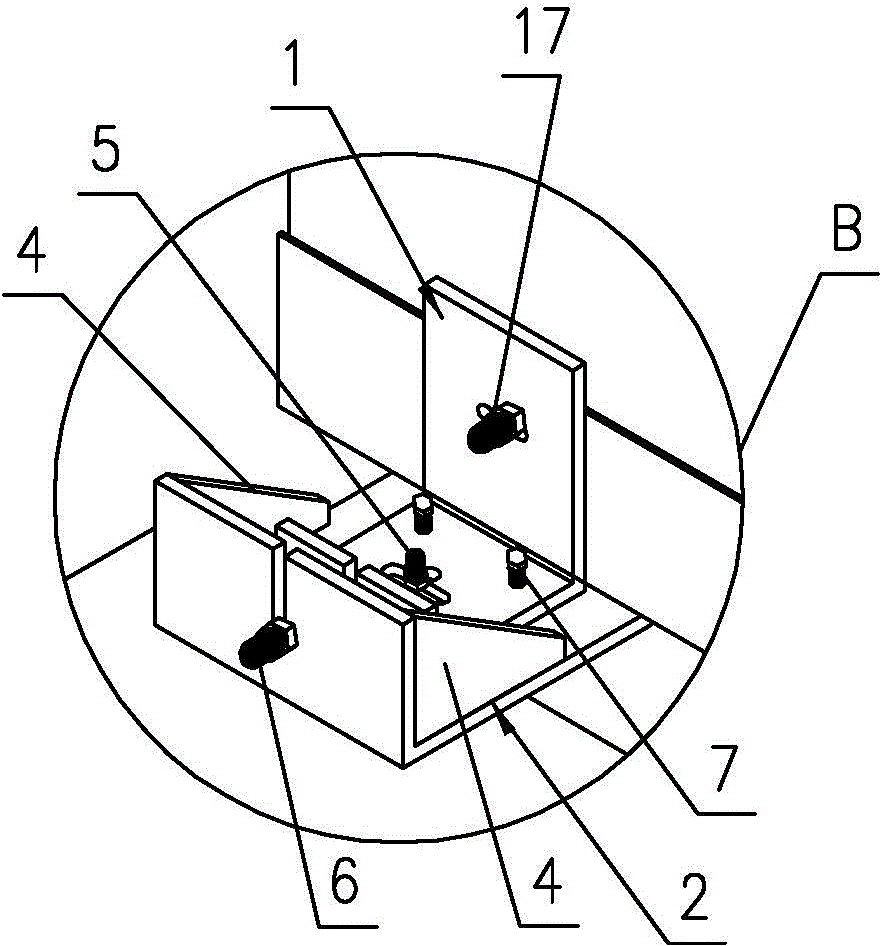

[0028] like Figure 1~6 As shown, it is a connection structure of a multifunctional lightweight concrete curtain wall of the present invention, which includes a fixing piece and a pair of steel L-shaped plate parts, and the fixing piece adopts bolts 5, and one of the L-shaped plate pieces is an upper L-shaped plate 1, the other L-shaped plate is the lower L-shaped plate 2, the transverse plate 21 of the lower L-shaped plate 2 supports the transverse plate 11 of the upper L-shaped plate 1, and the vertical plate of the upper L-shaped plate 1 The facing plate 12 is connected with the lightweight concrete slab 3 through bolts 17, the transverse plate 21 of the lower L-shaped plate 2 is used to connect with the main structure of the building, and the transverse plate 11 of the upper L-shaped plate 1 is provided with a ( figure 1 The strip-shaped hole 13 extending in the X direction shown in the figure), the transverse plate surface 21 of the lower L-shaped plate 2 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com