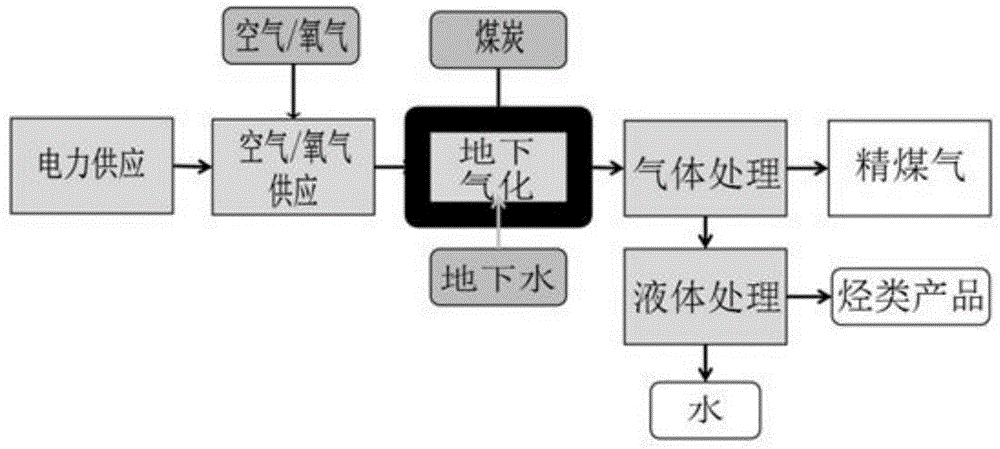

A method of underground gas production by air fracturing and micro-negative pressure

A micro-negative pressure and air pressure technology, applied in earthwork drilling, production fluid, wellbore/well components, etc., can solve problems such as inability to guarantee UCG gasification efficiency and gas production, difficult operation, water-sensitive pollution, etc. , to achieve the effect of low environmental requirements for coal seam ignition, wide application range and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

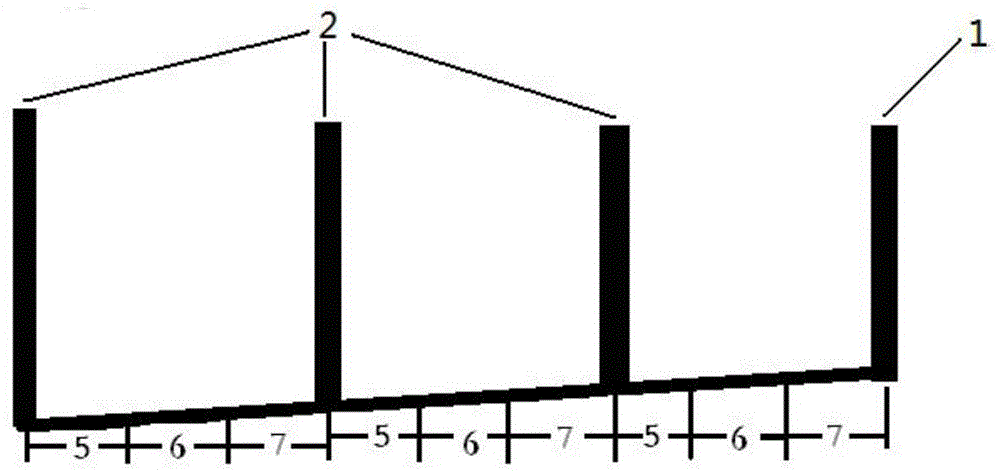

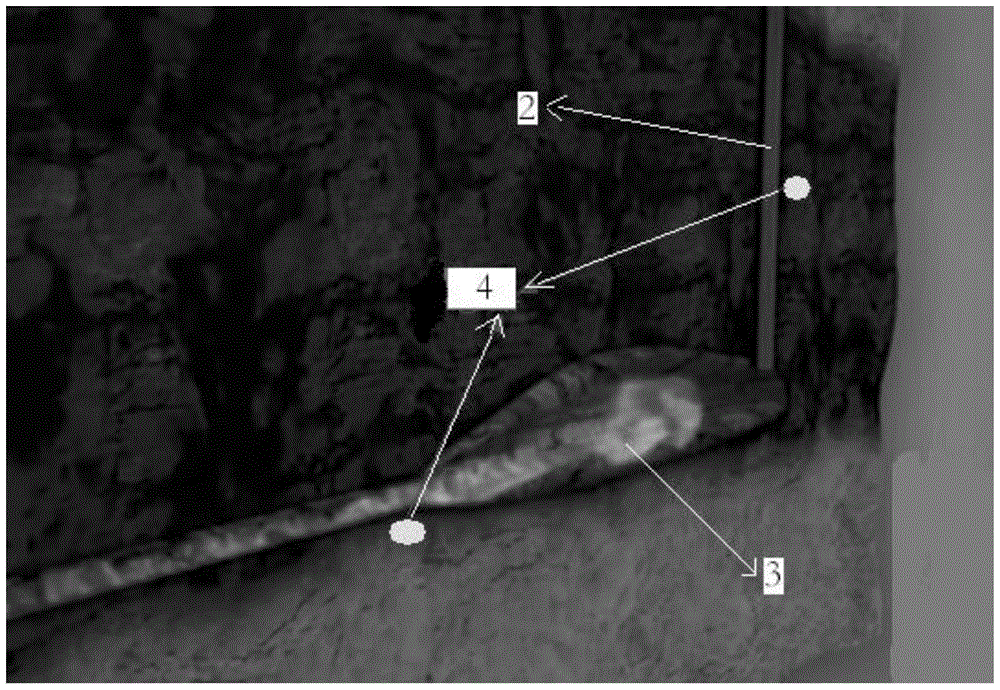

[0049] In this embodiment, a total of four holes with a diameter of about 250 mm are drilled at intervals of about 150 meters on the ground. After hitting the lowest part of the coal seam, the holes are drilled horizontally to connect the gasification channel to form a gasifier, such as figure 2 As shown, it includes 1 gas inlet well and 3 gas outlet wells. The coal seam generally has a certain inclination angle. The first gas outlet well is located at the lowest position of the coal seam, and is ignited in the lower part of the coal seam, burning from bottom to top. The length ratio of the oxidation section 5, the reduction section 6 and the dry pyrolysis section 7 in the gasification channel is 0.9-1.1:0.9-1.1:1.2. The sensor 4 is set underground to monitor the temperature and gas composition of the underground reaction; the sensor 4 is put into the underground pre-buried monitoring point through the casing, such as image 3 shown.

[0050] In this embodiment, non-caking c...

Embodiment 2

[0058] In this embodiment, lignite with a water content of 16% and a calorific value of 4,700 kcal is used, and a gasifying agent is introduced, and the oxygen and CO in the gasifying agent are 2 The ratio is 6:4, using a method similar to Example 1, after micro-negative pressure underground gasification, the composition of the crude gas produced by the gas outlet well is as follows: 6% methane, 26% carbon monoxide, 23% hydrogen, carbon dioxide, sulfur dioxide, sulfide Hydrogen and water vapor etc. account for 45%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com