A plate-type rapid quantitative loading system and method

A loading system and plate-type technology, which is applied in the field of loading and conveying bulk materials and mechanical systems, can solve problems such as increasing the cost and maintenance costs, reducing the bearing capacity of the well wall, and destroying the continuity of the wellbore, so as to simplify the amount of equipment and ensure Strength, reducing engineering difficulty and the effect of engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

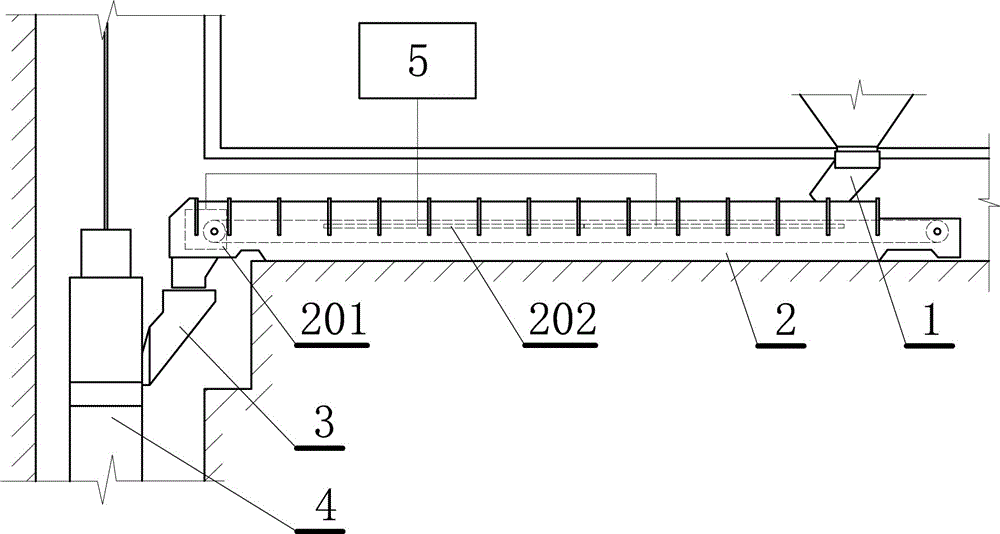

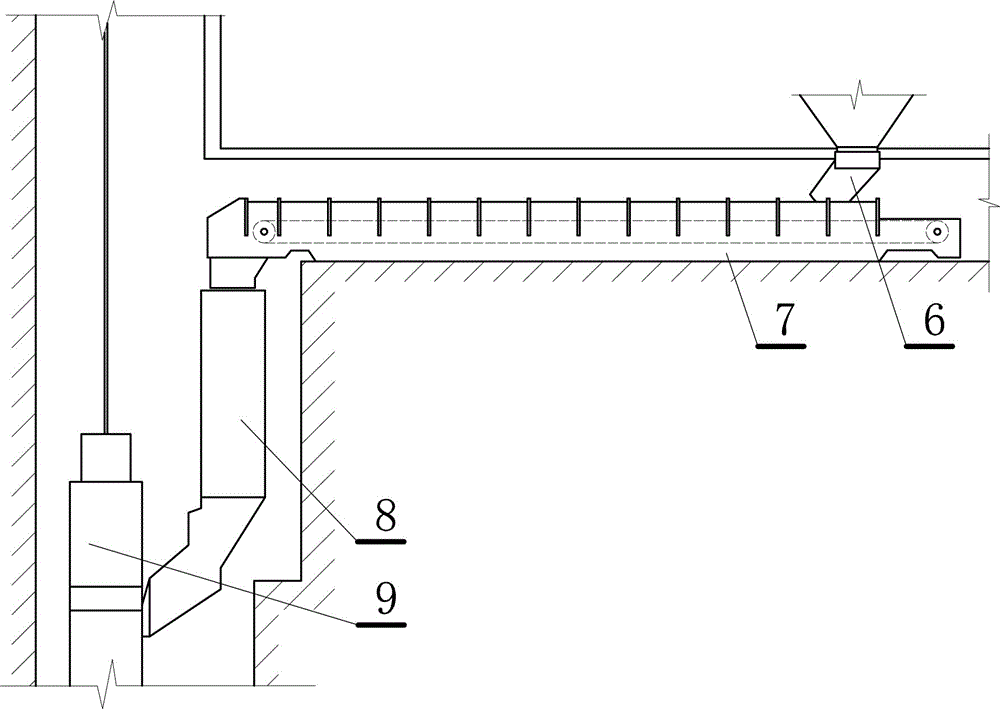

[0029] This embodiment is a plate-type rapid quantitative loading system, such as figure 1 shown. This embodiment includes: a coal bunker 1, the feeding end of the storage type apron quantitative conveyor 2 is arranged below the coal bunker, and the inlet of the skip loading chute 3 is arranged at the discharge end of the storage type apron quantitative conveyor, The outlet of the skip loading chute faces the upper mouth of the skip 4, and the power of the storage-type apron quantitative conveyor is formed by a variable-speed transmission device 201, and the storage-type apron quantitative conveyor is provided with a plurality of scales The weighing sensor is electrically connected to the weighing device 202 , and the weighing device and the variable speed transmission are electrically connected to the central controller 5 .

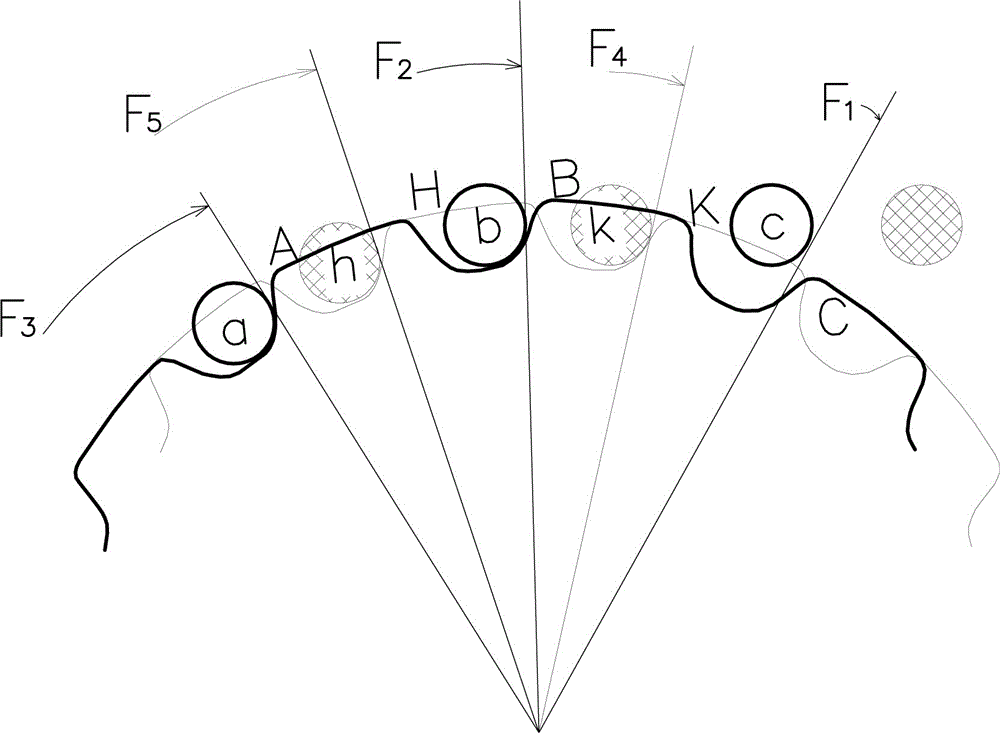

[0030] The train of thought of this embodiment is to get rid of the traditional downhole quantitative hopper for charging the skip. By replacing the b...

Embodiment 2

[0048] This embodiment is an improvement of the first embodiment, and is a refinement of the first embodiment on the variable speed transmission. The variable speed transmission device described in this embodiment includes: a set of high speed transmission device and a set of low speed transmission device.

[0049] The conveyor described in this embodiment selects two simple operating speeds: combining the coal loading speed and the unloading speed. There are also two ways to form two speeds:

[0050] One is a special explosion-proof two-speed motor, which is equipped with 4 / 32 poles or 8 / 32 poles according to different models and different fast and slow speeds. The two-speed motor is small in size and simple in structure, but every time the skip is lifted, it needs to switch between fast and slow speeds. The transmission mode of the two-speed motor causes high heat and high failure rate due to frequent switching between fast and slow speeds, while the air-cooled two-speed mo...

Embodiment 3

[0053] This embodiment is an improvement of the first embodiment, and is a refinement of the first embodiment on the variable speed transmission. The variable-speed transmission device described in this embodiment is a frequency-variable speed-regulating motor driven by a transmission, and the frequency-variable speed-regulating motor is connected with a frequency-variable speed regulator.

[0054] This embodiment adopts the drive technology of variable frequency speed regulation to generate coal loading speed, buffer speed and unloading speed. Especially improving the unloading speed can improve the speed of carrying coal to the skip. The method of frequency conversion speed regulation can also intelligently carry out overall control. By actively tracking the operation parameters such as the position and speed of the skip, the operation strategy of the conveyor can be adjusted in real time through the central controller to realize synchronous operation with the skip. No down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com