Pneumatic Oil Limiting Device for Mixed Combustion Engine

An engine and oil-limiting technology, which is applied to combustion engines, internal combustion piston engines, engine components, etc., can solve problems such as difficult adjustment, high cost, and complicated installation, and achieve the effect of meeting economical operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

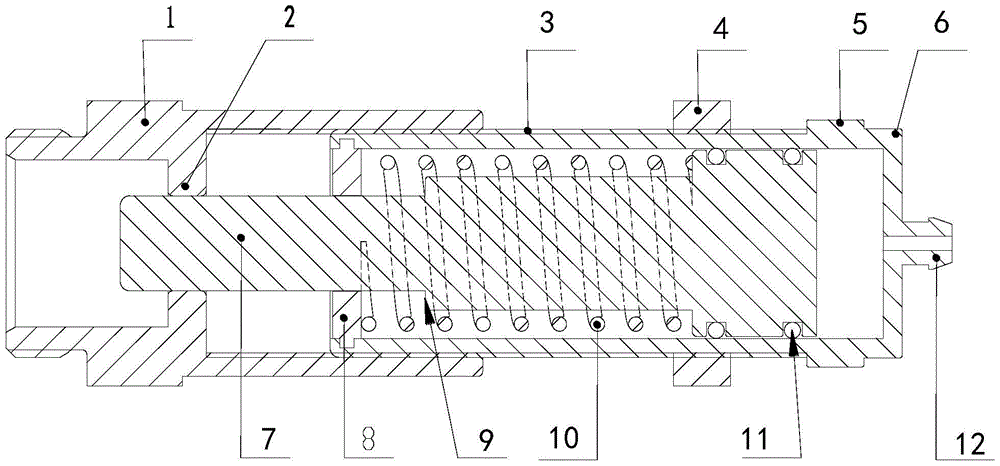

[0012] Such as figure 1 As shown, a pneumatic oil limiting device for a mixed-combustion engine includes a connecting seat 1 and a cylinder connected to the connecting seat 1; the cylinder includes a cylinder block 6 and a piston 7, and the cylinder block 6 is provided with a piston limit retaining ring 8, and the piston limit The function of the retaining ring 8 is to adjust the stroke of the piston 7 by cooperating with the limit step 9 on the piston rod. The outer wall of the cylinder body 6 is provided with an adjustment thread 3. The function of the adjustment thread 3 is to cooperate with the lock nut 4 to adjust the cylinder. The distance between the connecting seat 1 and the cylinder body 6 is provided with an air nozzle 12. The function of the air nozzle 12 is to realize the air intake inside the cylinder body to push the piston 7 to run. The piston rod of the piston 7 is provided with a limit step 9, and the piston 7 The piston rod located in the cylinder body 6 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com