A channel device hydraulic control system for sugarcane harvester

A hydraulic control system and channel device technology, which is applied to harvesters, fluid pressure actuators, mechanical equipment, etc., can solve the problems of large space occupied by multiple pipelines, unfavorable energy saving, and high power consumption of parallel circuits, etc., to achieve reduction Effects of piping connections and spatial layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

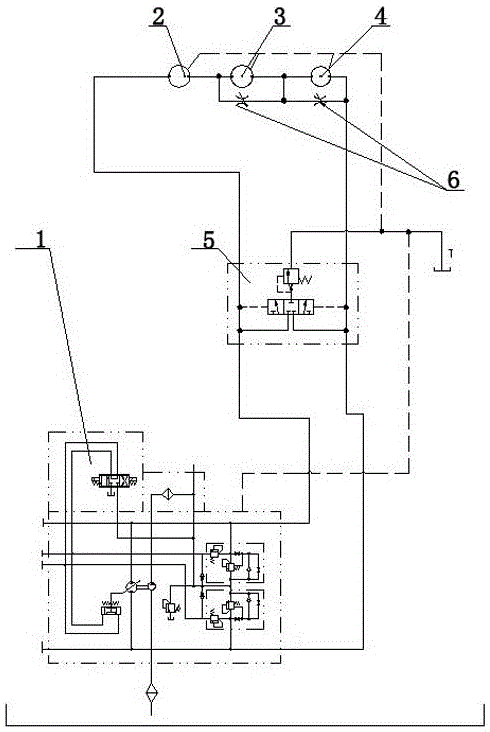

[0009] As shown in the figure, a channel device hydraulic control system of a sugarcane harvester includes a closed hydraulic pump 1, a stripping hydraulic motor 2, a splitting hydraulic motor 3, an output hydraulic motor 4, a flushing valve 5 and a throttle valve 6, The closed hydraulic pump 1 is connected to the push rod handle of the control room through a flexible shaft coupling, and the continuous adjustment of the displacement can be realized by connecting the flexible shaft coupling through an external control knob. The closed hydraulic pump 1 is connected in series with the stripping hydraulic motor 2, the splitting hydraulic motor 3 and the output hydraulic motor 4 in sequence to form a closed circuit. The motor is a quantitative motor, which can provide high torque output when rotating at a low speed. Leaf stripping is a relatively important task in the channel. It is measured through experiments that high speed and large torque are required for leaf stripping. The le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com