Patents

Literature

39results about How to "Reduce overall layout space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

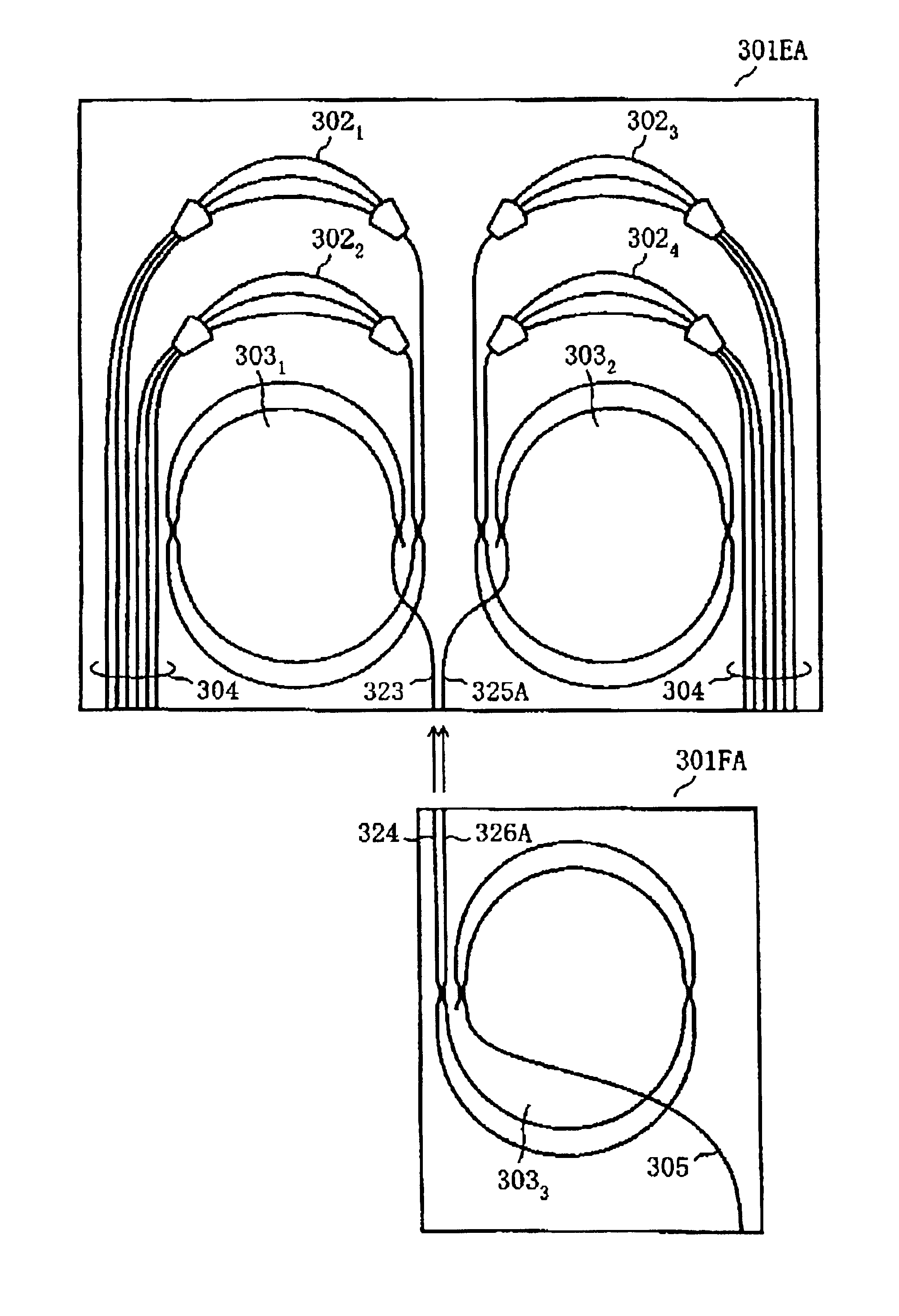

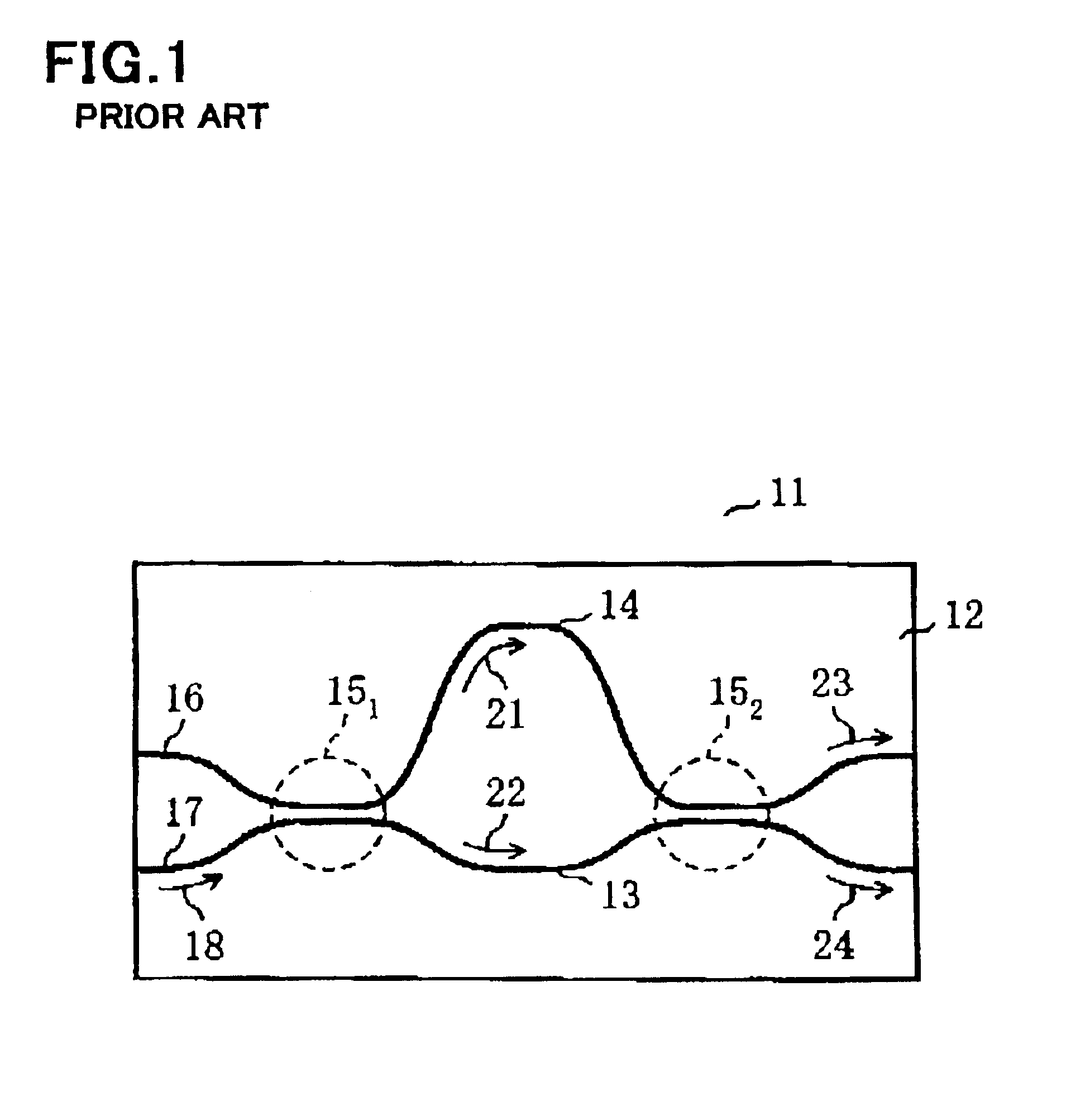

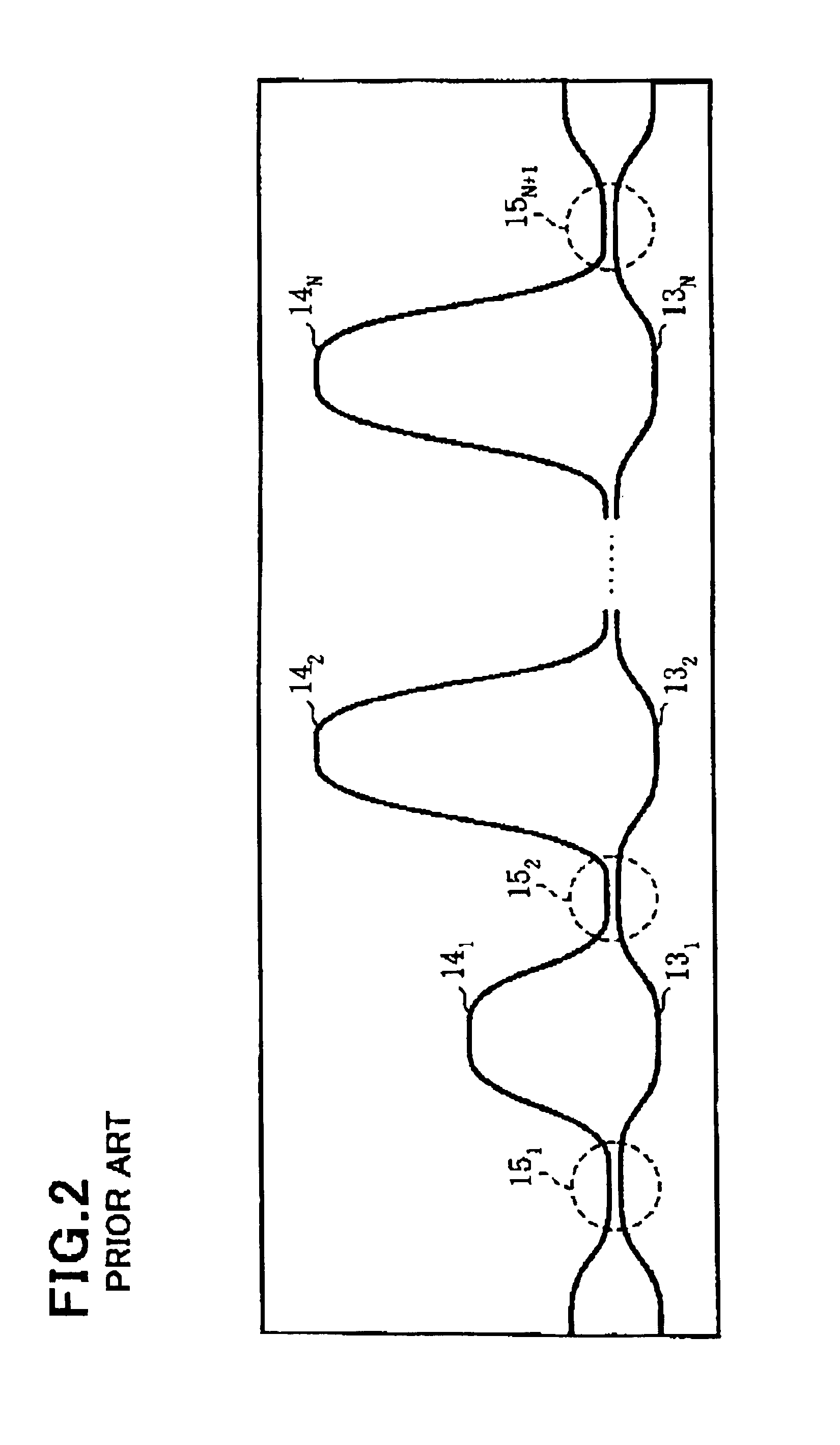

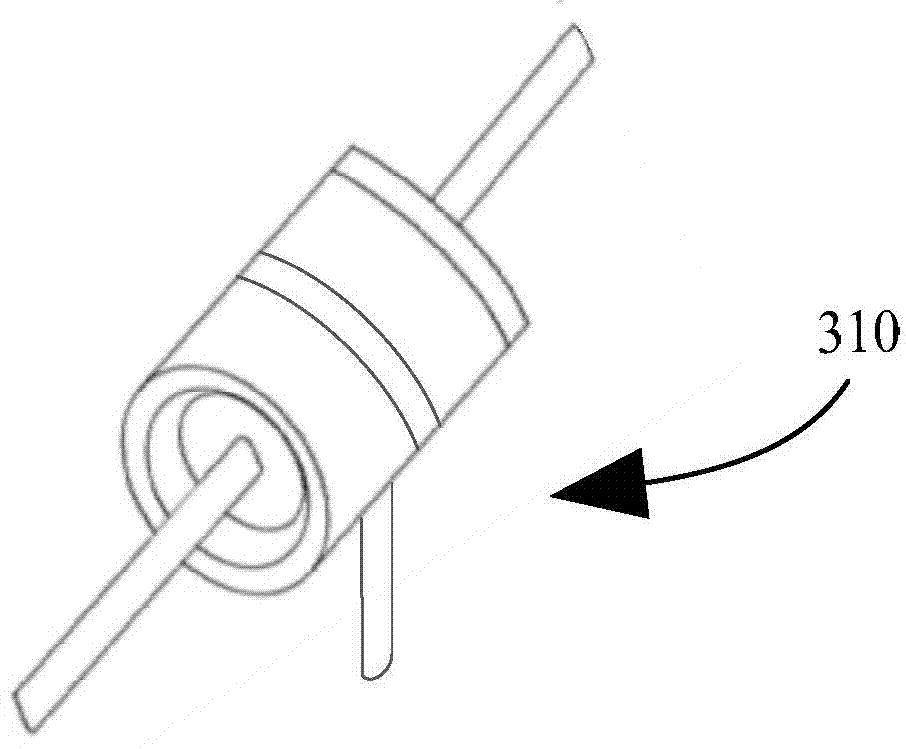

Spiraling optical device

InactiveUS6922510B2Reduce overall layout spaceCoupling light guidesOptical waveguide light guideEngineering

Owner:NEC CORP

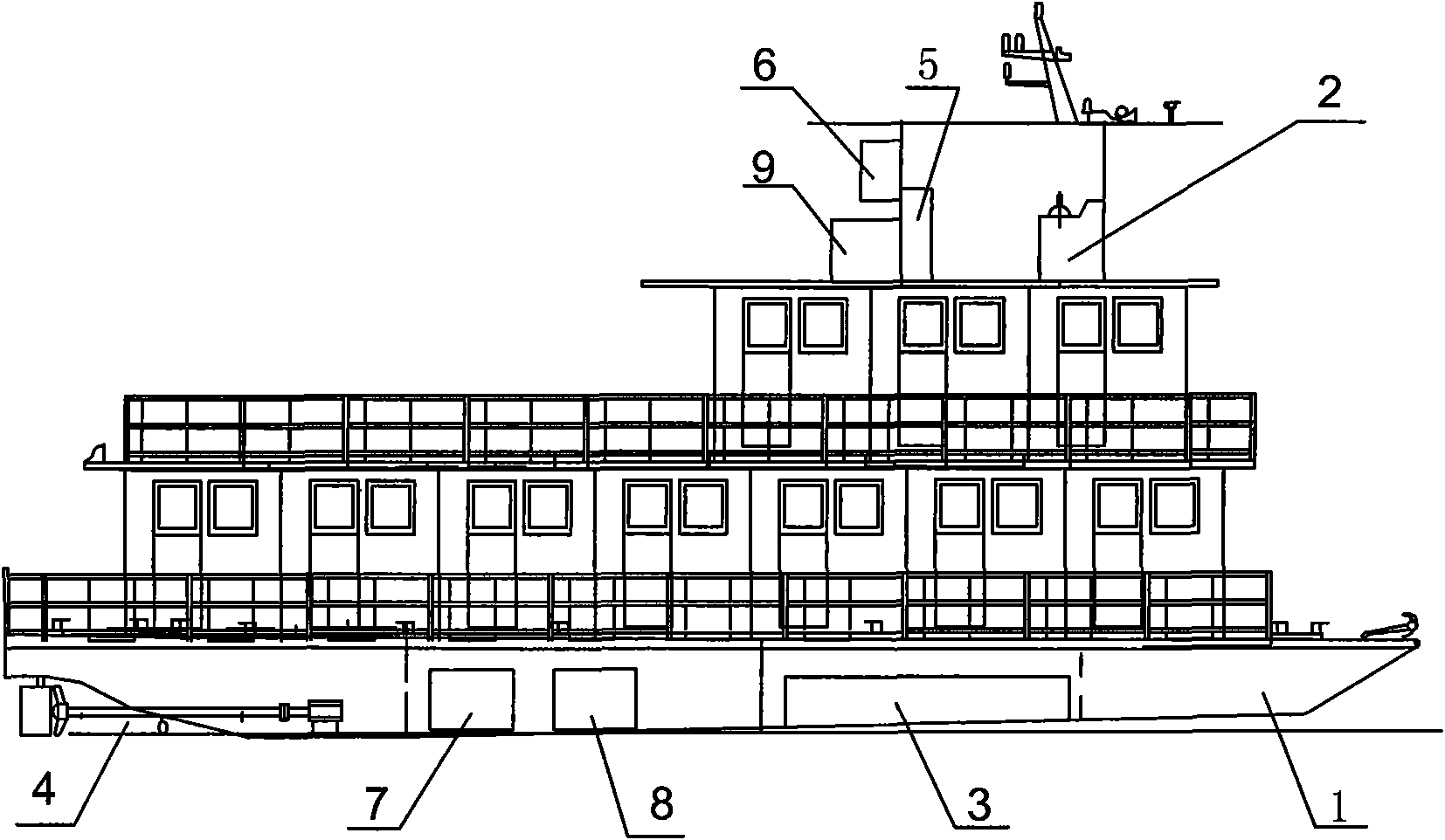

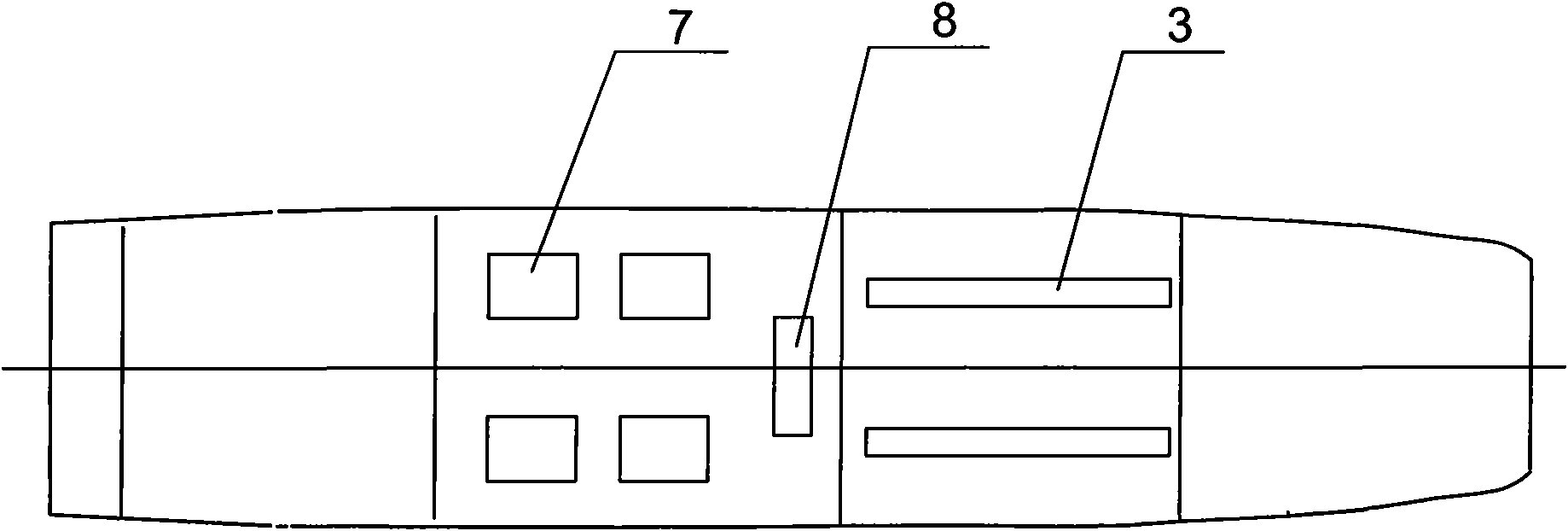

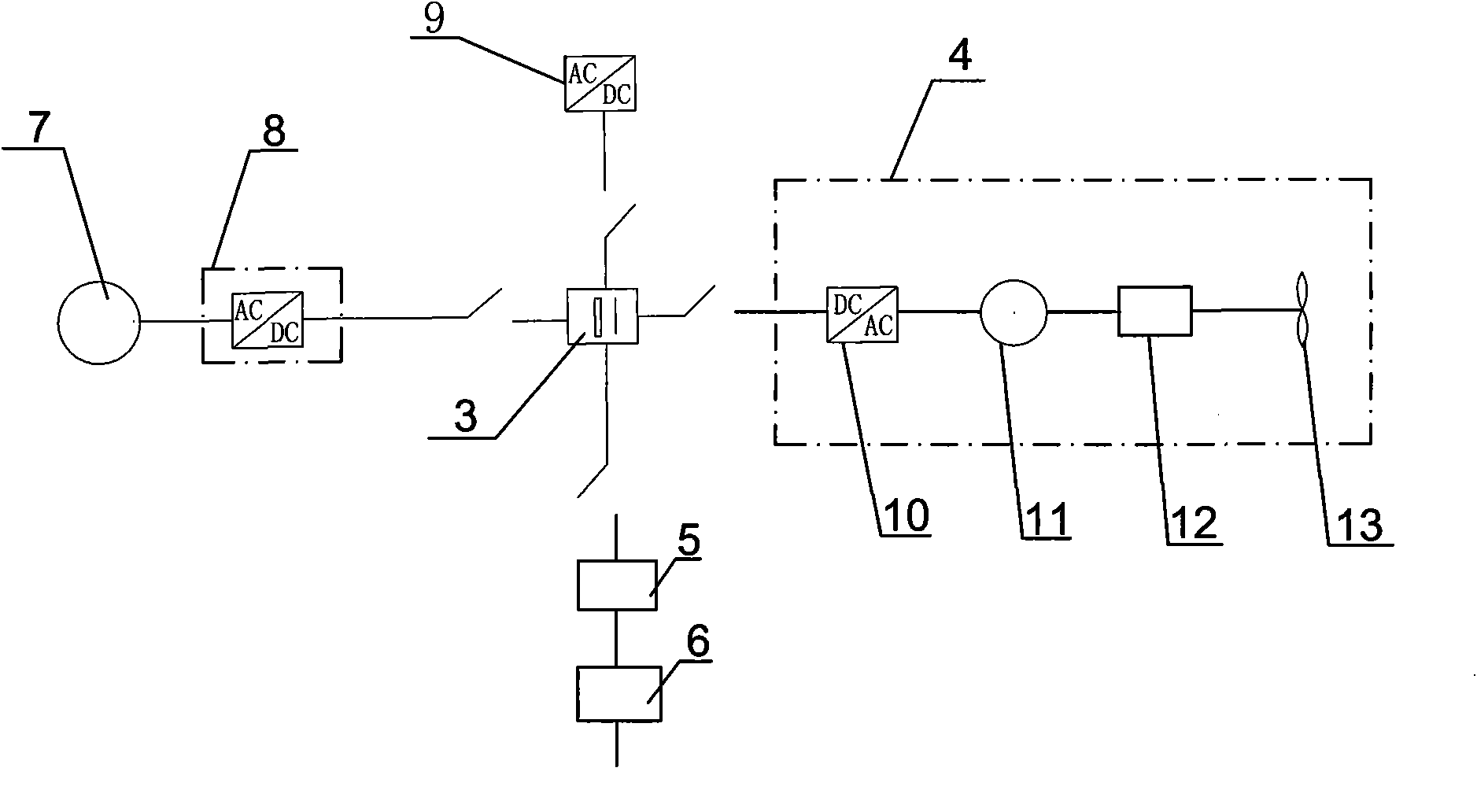

Oil-electric combined charge long-distance all-electric ship with storage battery

InactiveCN101585407AReduce idling lossImprove efficiencyPropulsion power plantsPropulsion using engine-driven generatorsHybrid typeEnvironmental resistance

An oil-electric combined charge long-distance all-electric ship with storage battery is disclosed, a pilothouse of a ship body is inside provided with a console, an electric propulsion device is arranged at stern, a battery pack is mounted at the bottom of the ship body, and the ship body is also provided with a thermoelectric generating set that is connected with a distribution board having a rectifier. By mounting the battery pack and the thermoelectric generating set on the ship, the invention can utilize two energies including shore power and high energy fuel, and can sufficiently utilize clean energy at locations where the shore power is present, in order to reduce smoke dust, noise, odor and oil / water pollution and to improve working environment on the ship. The invention regards the high energy fuel and the shore power as a composite energy to achieve energy balance, forms a ship electric station with the storage battery centered in a charging way in order to realize full-power propelling, and integrates the advantages of storage battery electric ship and traditional internal combustion engine ship with a view to double index of environment protection and energy conservation as well as endurance. The invention has the characteristics of accuracy control, high endurance, environment protection, energy conservation, and simple and convenient management and operation, and is the electric ship similar to oil-electric hybrid electric vehicle.

Owner:宜昌发中船务有限公司 +4

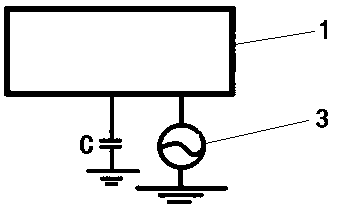

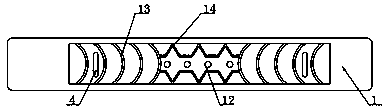

Gas discharge tube

ActiveCN103762143AImprove flow capacityIncrease the arc pressure valueSolid cathode detailsOvervoltageEngineering

The invention provides a gas discharge tube. The gas discharge tube comprises a discharge tube body and an overvoltage protective board, wherein a plurality of voltage-limiting components are arranged inside the overvoltage protective board or on the outer surface of the overvoltage protective board, the number of the voltage-limiting components is equal to that of intermediate electrodes, and the voltage-limiting components are electrically connected with the intermediate electrodes in a one-to-one mode. The protection effect is better, the response speed is higher, and reliability is higher. The discharge tube body and the overvoltage protective board are electrically connected and are integrated together, and when the gas discharge tube is applied to an overvoltage protection circuit, the working procedure of welding of the voltage-limiting components is omitted; when the gas discharge tube is applied, the welding technology is simple, processing is easier and more convenient, processing efficiency is improved, the layout area and the space of a whole circuit board are reduced, and layout of the circuit board can be conveniently and reasonably planned.

Owner:SHENZHEN BENCENT ELECTRONICS CO LTD

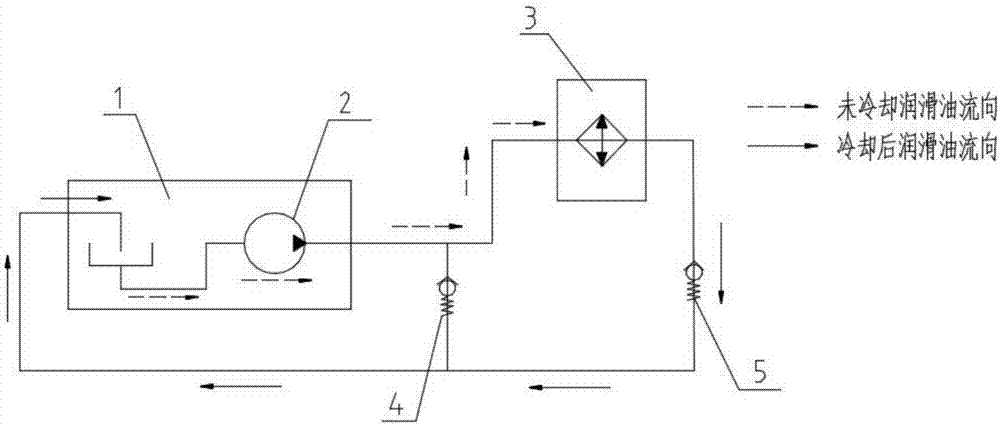

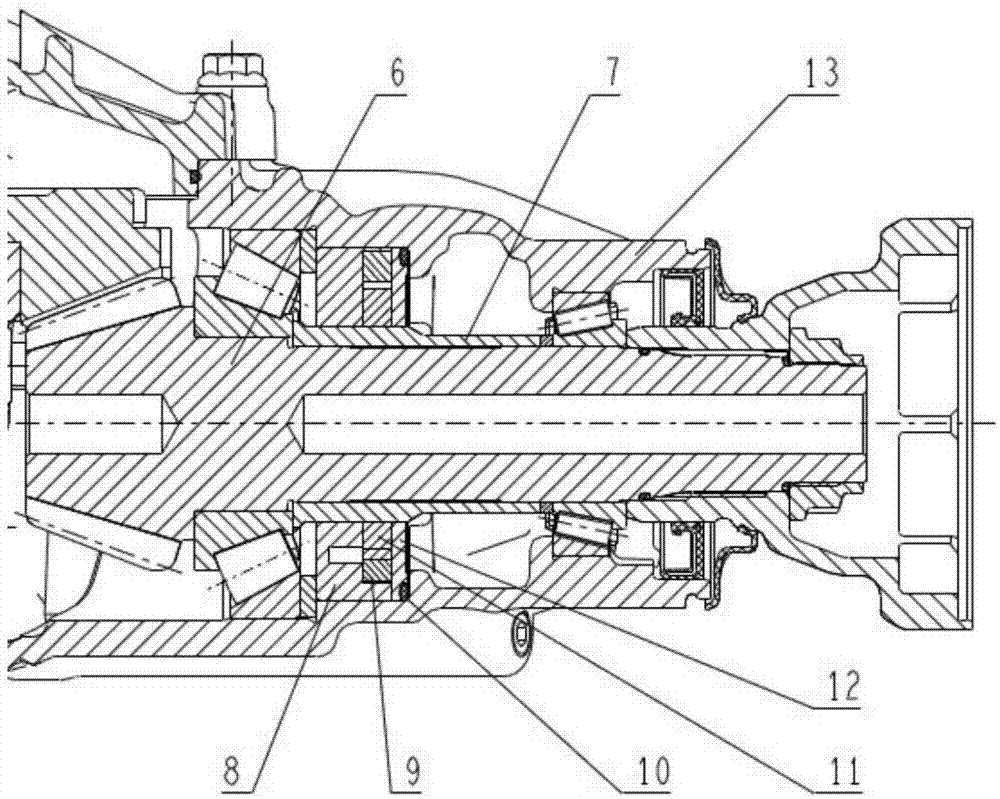

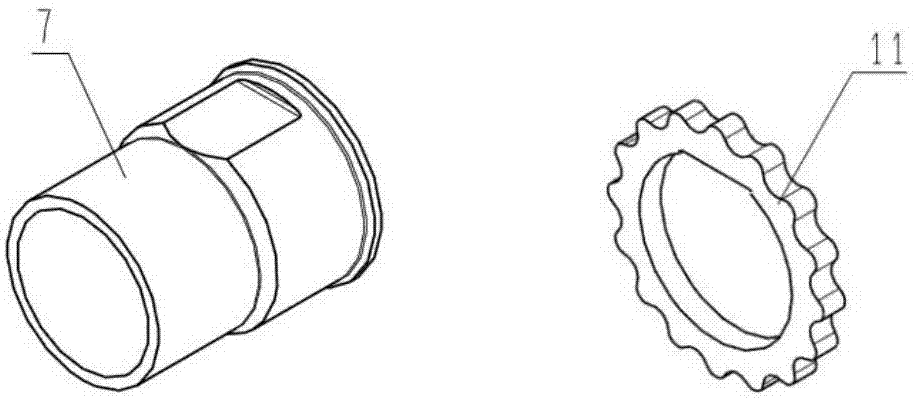

Drive axle lubricant external circulation cooling system

InactiveCN107289119AExtend your lifeExtended replacement cycleGear lubrication/coolingVehicle componentsReducerPinion

The invention discloses a drive axle lubricant external circulation cooling system. A built-in cooling oil pump and an axle drive bevel pinion of a drive axle are integrated; when a drive axle assembly works, the cooling oil pump sucks in a lubricant at the bottom of the drive axle assembly through a lubricant channel; the lubricant enters a lubricant cooler through an oil outlet pipe; the cooled lubricant enters a main reducer housing through an oil return pipe and finally returns back into the drive axle assembly; a one-way valve is arranged on the oil return pipe; and an unloading valve is arranged between the oil outlet pipe and the oil return pipe. Through the scheme of external circulation of the cooled lubricant, the problem of slow lubricant cooling of the automobile drive axle assembly is solved, the problems that the drive axle assembly of an external oil pump cooling system is large in arrangement space and high in cost are solved, and the problem that the external circulation system cannot protect the drive axle assembly or the cooling system when the cooler is damaged or the pipeline is blocked is also solved.

Owner:CHINA FIRST AUTOMOBILE

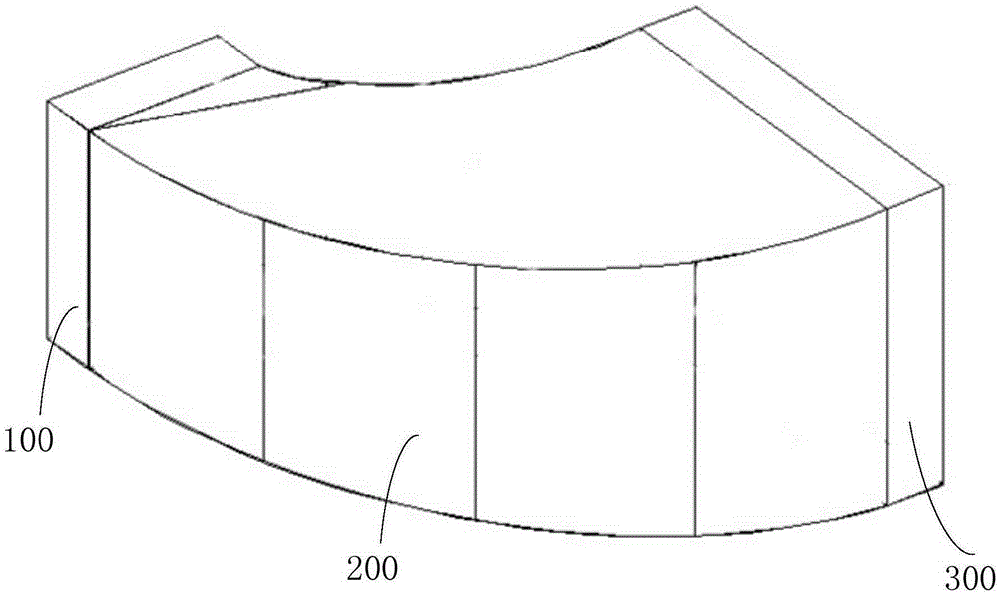

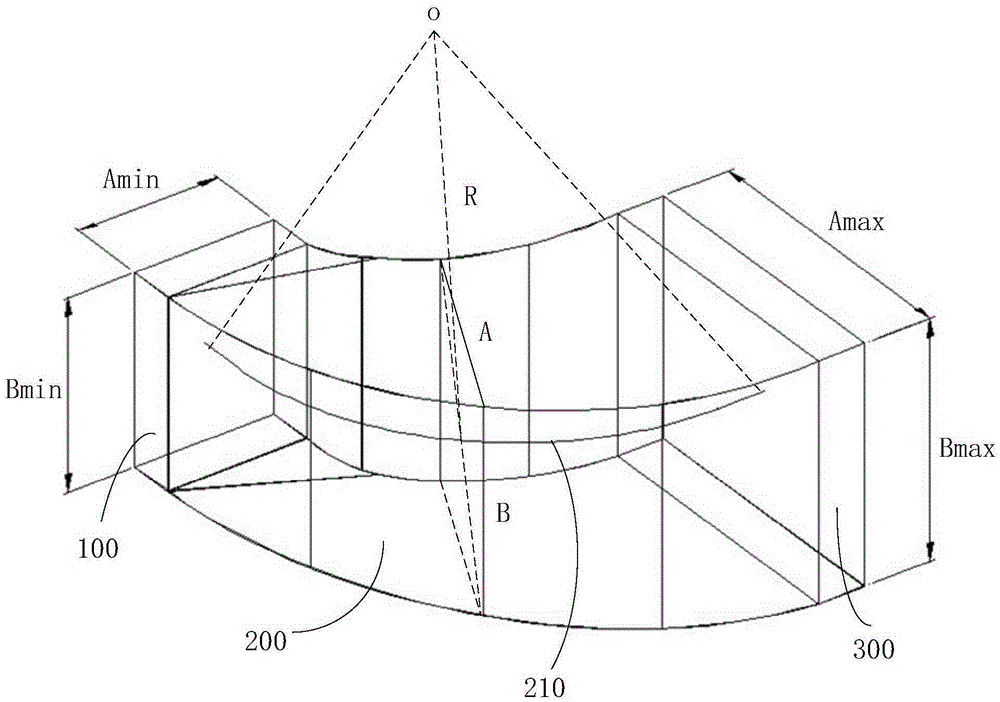

Novel reducing square bend and flue gas pipeline system

The invention discloses a novel reducing square bend and a flue gas pipeline system. The novel reducing square bend comprises a large end, a small end and a reducing segment in smooth transition connection with the large end and the small end. The cross section of the large end, the cross section of the small end and the cross section of the reducing segment are all quadrilateral. On the reducing segment, R=1-5 D, wherein R is the radius of curvature of any point on the center line of the reducing segment, and D is the length of the long diagonal of the quadrangle of the cross section of the point. According to the novel reducing square bend, pipeline transition is smooth, and therefore a flue gas flow field in a pipeline is even, and vibration and noise of the pipeline are reduced.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

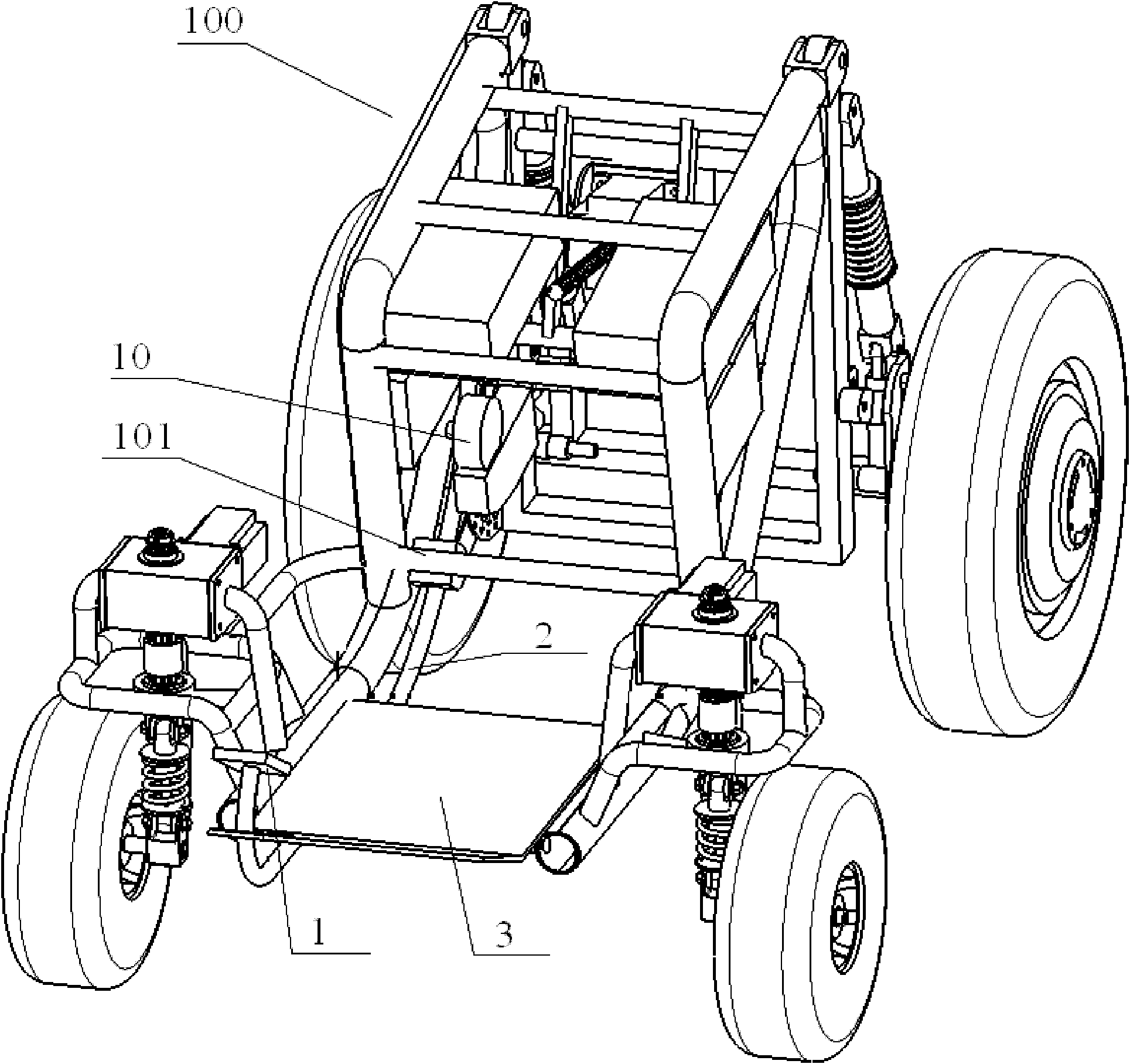

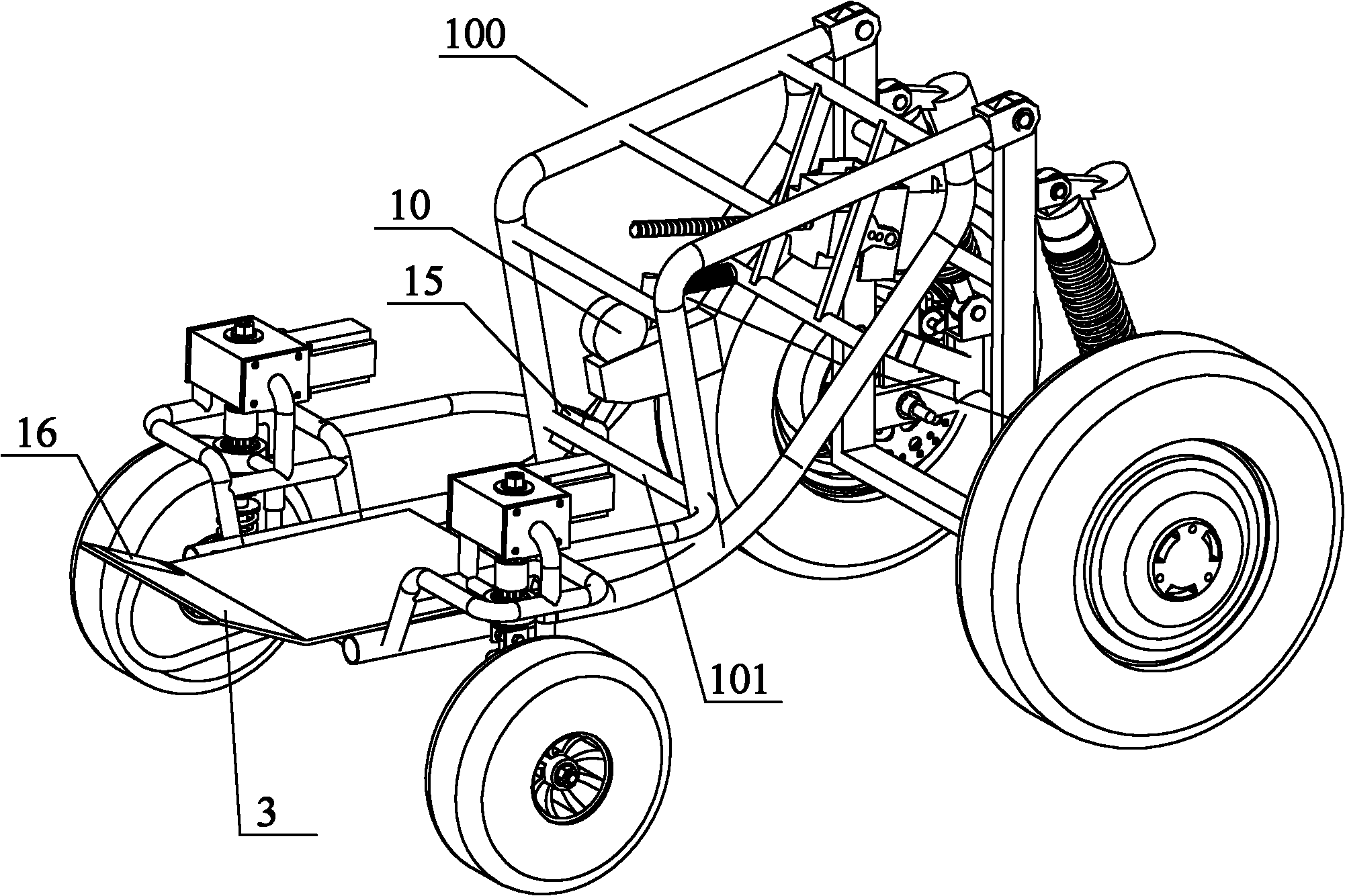

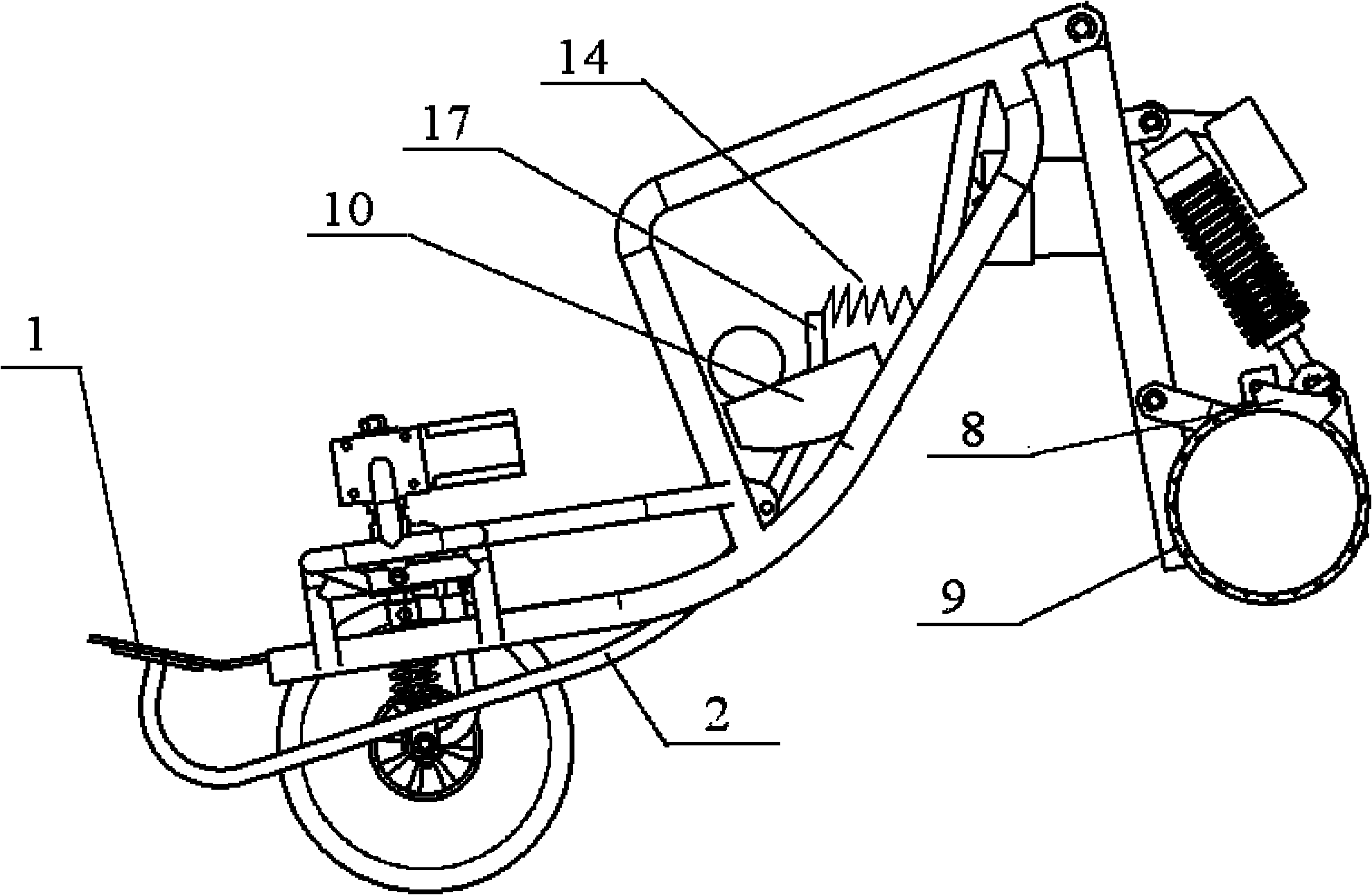

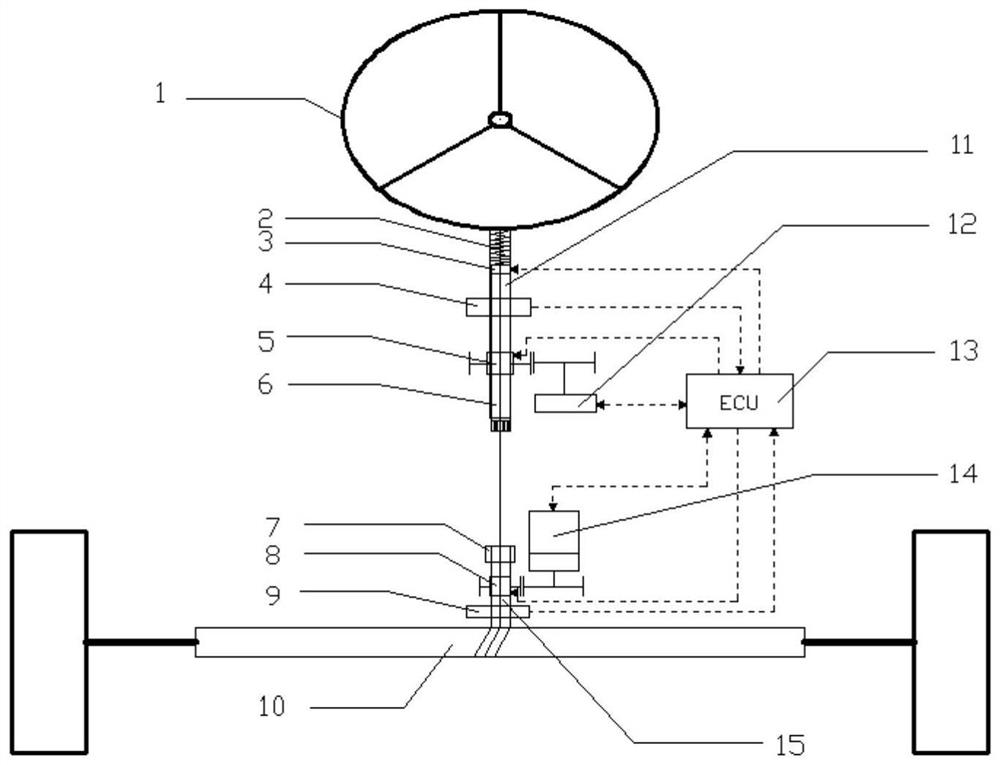

Manually-operated and linearly-controlled integrated brake system

InactiveCN102431533AEasy to get on and offReduce overall layout spaceMechanical braking transmissionVehicle frameActuator

The invention discloses a manually-operated and linearly-controlled integrated brake system, which comprises a transmission rod group, wherein the transmission rod group is arranged below a vehicle frame through an installation hole; the transmission rod group rotates around the installation hole; the front end of the transmission rod group is a pedal, and the rear end of the transmission rod group is a connection part; and the front side of the connection part is connected with a motor group which is connected with an electronic control unit (ECU), and the rear side of the connection part is connected with a brake actuator of a brake wheel. By adoption of the manually-operated and linearly-controlled integrated brake system, various kinds of working conditions such as mechanical brake, parking brake and automatic driving brake can be realized.

Owner:TONGJI UNIV +1

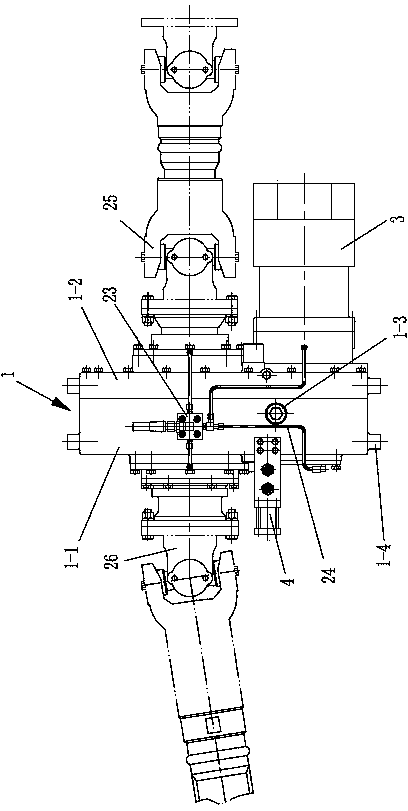

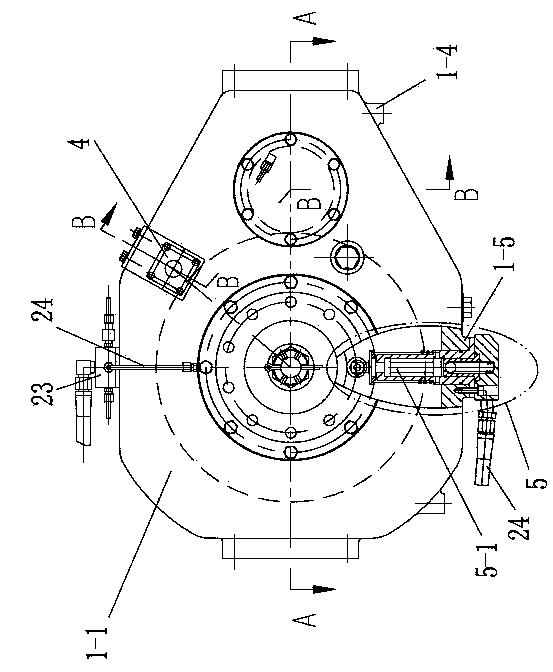

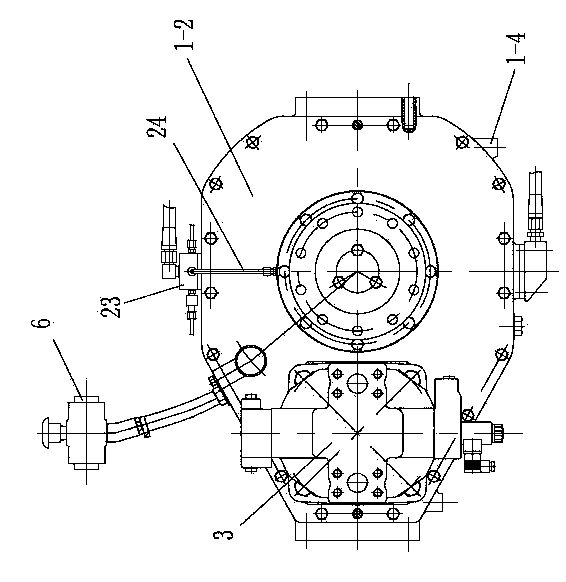

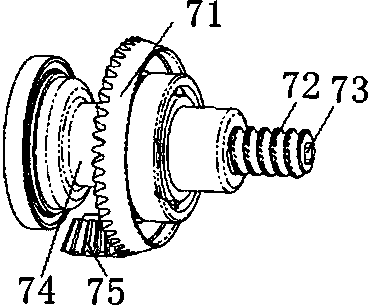

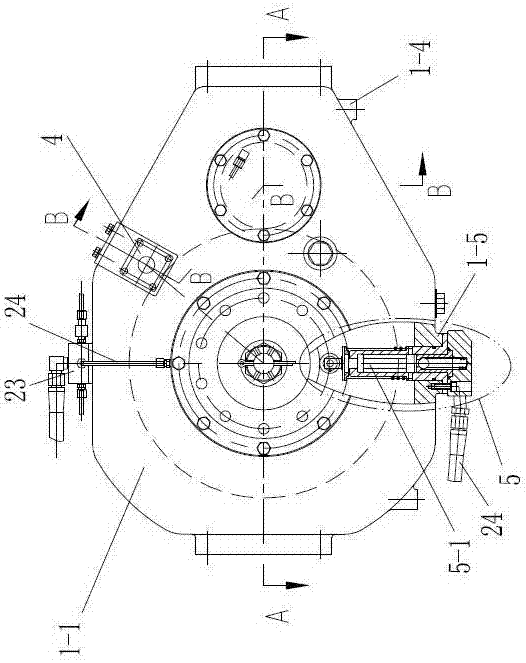

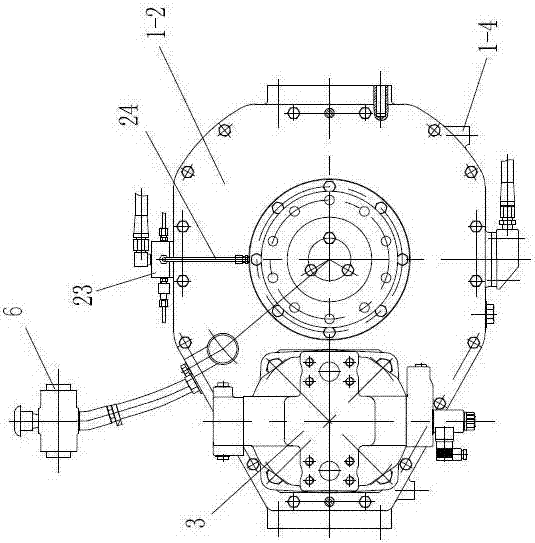

Power transmission case

ActiveCN103671805ASimple structureLow positioning accuracy requirementsGearboxesGearing controlClutchSubdivision surface

The invention discloses a power transmission case comprising a case body, an input shaft, an output shaft, a driving gear, a driven gear, a shift clutch, a toggle mechanism and a hydraulic motor. The case body comprises left case body and a right case body, subdivision surfaces of the left case body and the right case body are vertical planes, a bearing seat and an internal spline are arranged in a gear hole of the driving gear, two ball bearings are mounted in the bearing seat, the input shaft is provided with an external spline, the shift clutch is composed of a shift meshing sleeve, a meshing sleeve positioning mechanism and the internal spline of the driving gear, the meshing sleeve positioning mechanism is mounted on the input shaft, the shift meshing sleeve is provided with an internal spline and an external spline, the internal spline of the shift meshing sleeve is meshed with and in axial sliding fit with the external spline of the input shaft, the external spline of the shift meshing sleeve can be meshed with or separated from the internal spline of the driving gear, and the toggle mechanism comprises a toggle cylinder, a fork pull rod and a fork. The power transmission case is simple and reasonable in structure and easy to manufacture, the requirements for high-speed running and low-constant speed operating, running and driving of a rapid multifunctional operating vehicle are met.

Owner:CHANGZHOU RUITAI ENG MASCH CO LTD +1

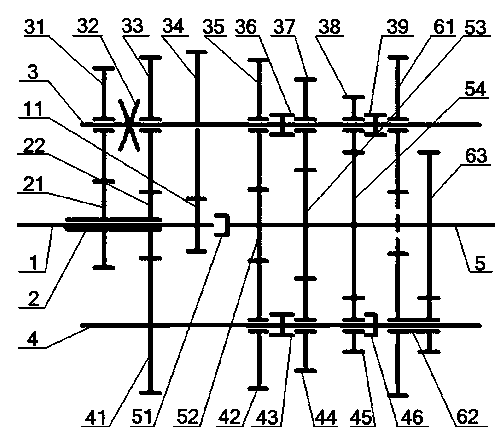

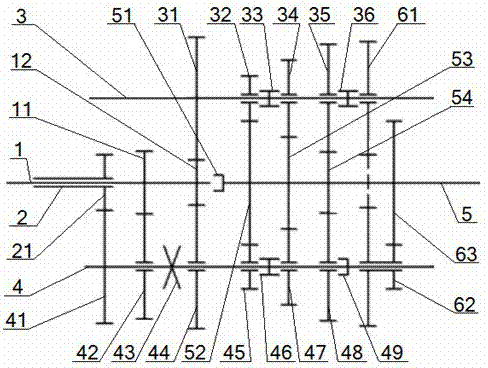

Double middle shaft transmission structure with hollow shaft synchronism and shifting method thereof

ActiveCN103821882ASave production cost and layout spaceShorten the lengthToothed gearingsGearing controlSynchronismMechanical engineering

The invention relates to a double middle shaft transmission structure with hollow shaft synchronism and a shifting method thereof. The structure comprises a solid input shaft and a hollow input shaft, wherein the solid input shaft is in transmission matching with an output shaft through an odd-shift middle shaft, the hollow input shaft is in transmission matching with an output shaft through an even-shift middle shaft, the hollow input shaft is sequentially sheathed with a fixing connecting synchronous gear of the hollow shaft and a fixing connecting gear of the hollow shaft from front end to tail end, the fixing connecting gear of the hollow shaft is respectively engaged with a hollow sheath synchronous gear of the odd-shift middle shaft and a fixing connecting gear of the even-shift middle shaft, the fixing connecting synchronous gear of the hollow shaft is engaged with the hollow sheath synchronous gear of the odd-shift middle shaft, the odd-shift middle shift is respectively in transmission matching with the hollow sheath synchronous gear of the odd-shift middle shaft and the hollow sheath gear of the odd-shift middle shaft through synchronous friction wheels, the fixing connecting gear of the odd-shift middle shaft is engaged with the fixing connecting gear of the solid input shaft, and the fixing connecting gear of the solid input shaft is sheathed on the solid input shaft. The structure has the advantages that the structure is simple, the arrangement space is little, the overhauling is convenient, and the production cost is low.

Owner:DONGFENG COMML VEHICLE CO LTD

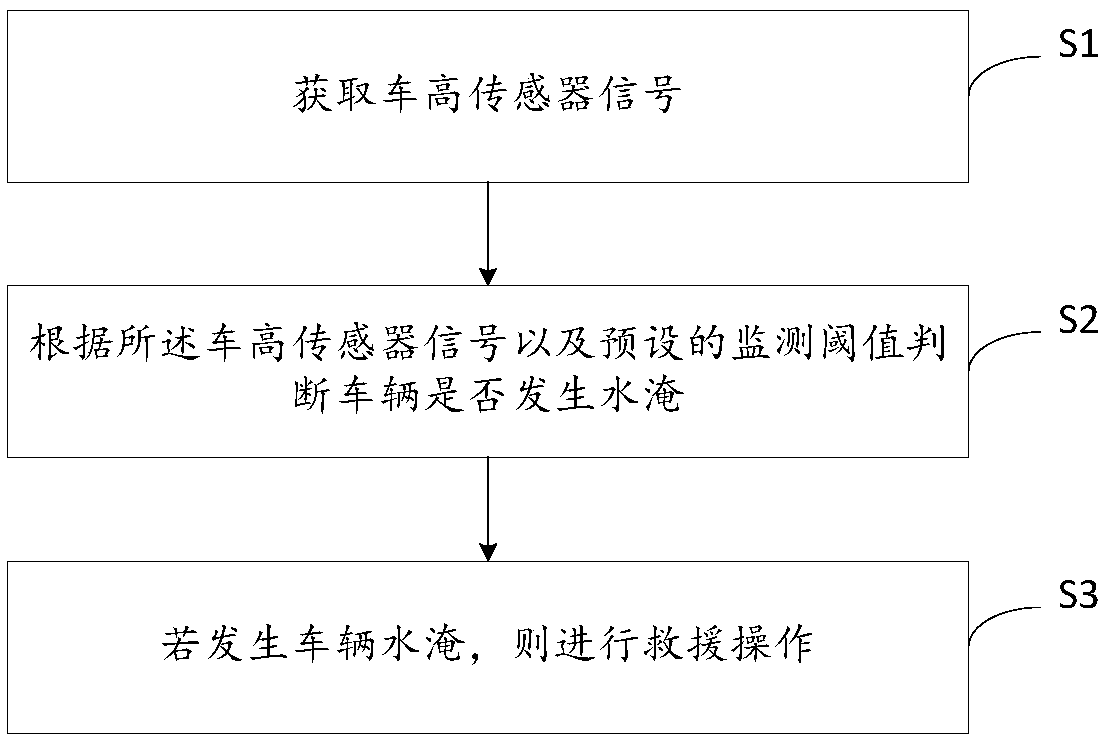

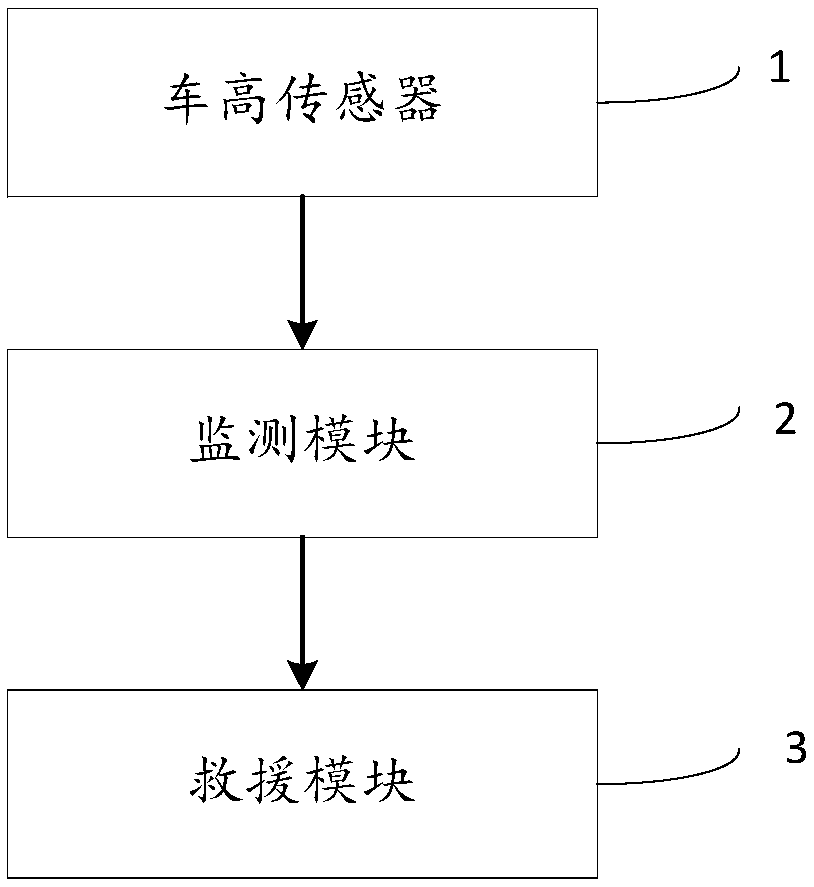

A vehicle water logging monitoring rescue method and system, a controller and a medium

InactiveCN110228433AWidely used valueImprove accuracyElectric/fluid circuitLoggingAutomotive engineering

The invention relates to a vehicle water logging monitoring rescue method and system, a controller and a medium. The method includes the steps of acquiring a vehicle height sensor signal; determiningwhether the vehicle is flooded according to the vehicle height sensor signal and a preset monitoring threshold; and performing a rescue operation if the vehicle is flooded. According to the invention,vehicle water logging is monitored through the vehicle height sensor signal, and a corresponding rescue measure is taken, thereby raising the accuracy and reliability of vehicle water logging monitoring.

Owner:NIO ANHUI HLDG CO LTD

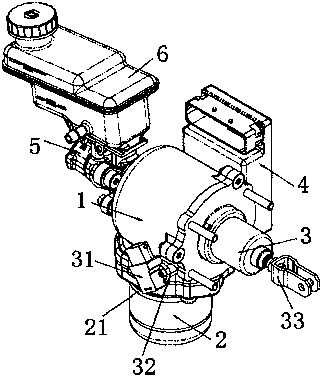

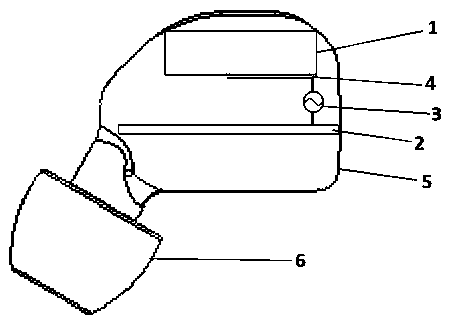

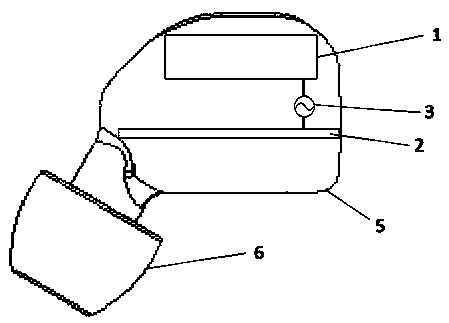

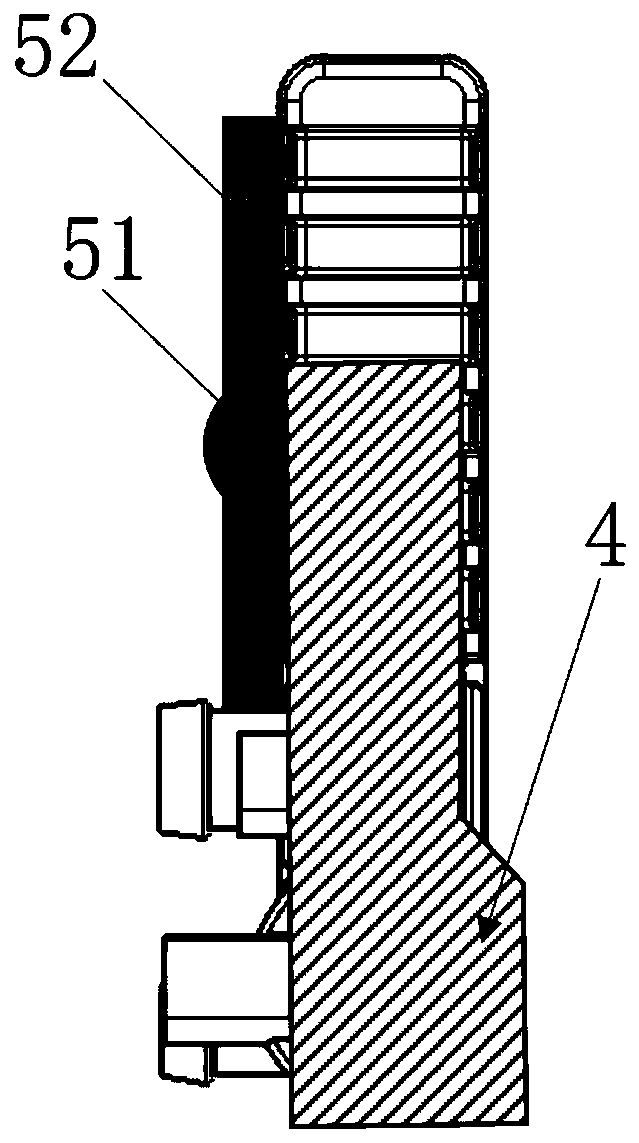

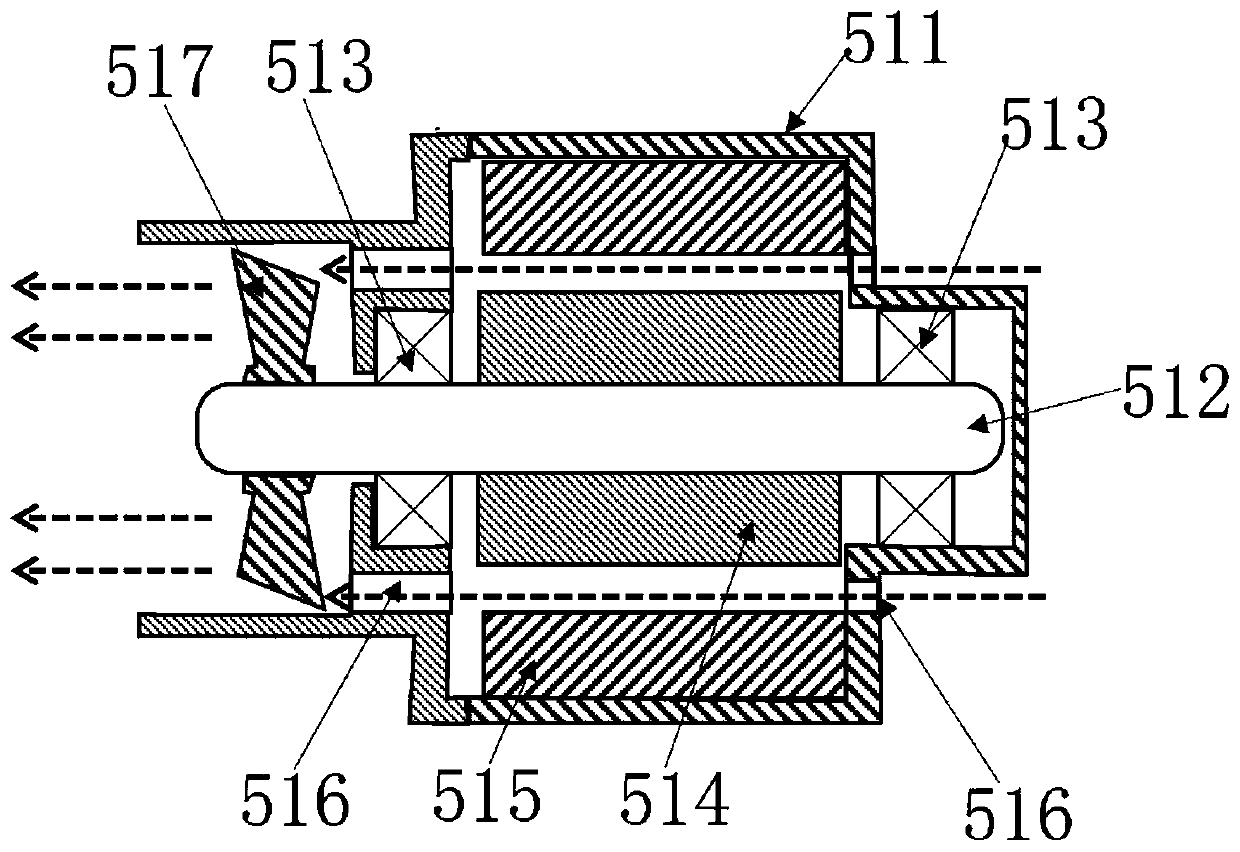

Motor protection type electric-controlled brake booster

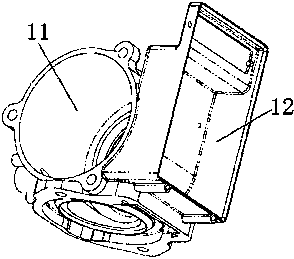

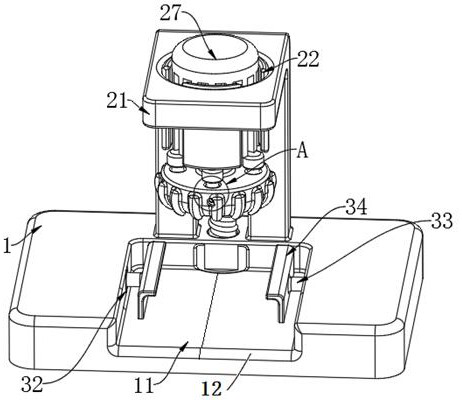

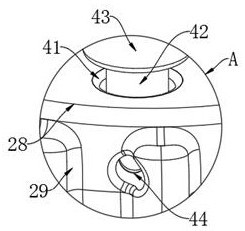

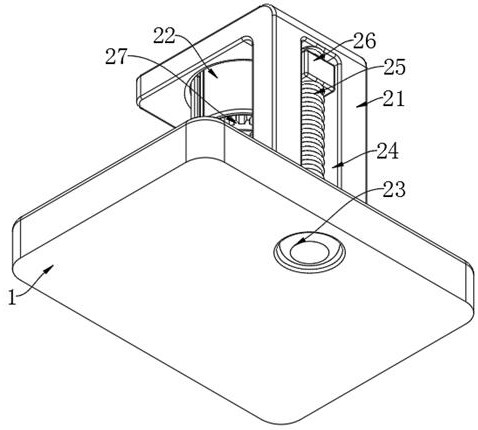

PendingCN107554510AImplement waterproofing measuresExtended service lifeBraking action transmissionRubber ringElectric machinery

The invention discloses a motor protection type electric-controlled brake booster, which comprises an electric motor, a driving mechanism, a pedal input mechanism, a shell body component, an electronic control unit, a main brake cylinder and a fluid storage tank; the pedal input mechanism is fixedly installed at the back end part of the shell body component, and the electric motor is fixedly installed at the lower end part of the shell body component; the main brake cylinder is further fixedly equipped with one fluid storage tank, and the driving mechanism is fixedly installed at the inner endpart of the shell body component. Through sheathing an annular motor cover on the outer surface of the electric motor and coating glue water to the joint between the motor cover and the shell body component or sealing by a rubber ring, while sealing the joint between the annular motor cover and the motor by the rubber ring also, the waterproof measure of the motor is effectively realized, the using environment requirement of arranging the booster assembly at an engine cabin is satisfied, and the service life of the motor is prolonged.

Owner:GELUBO TECH CO LTD

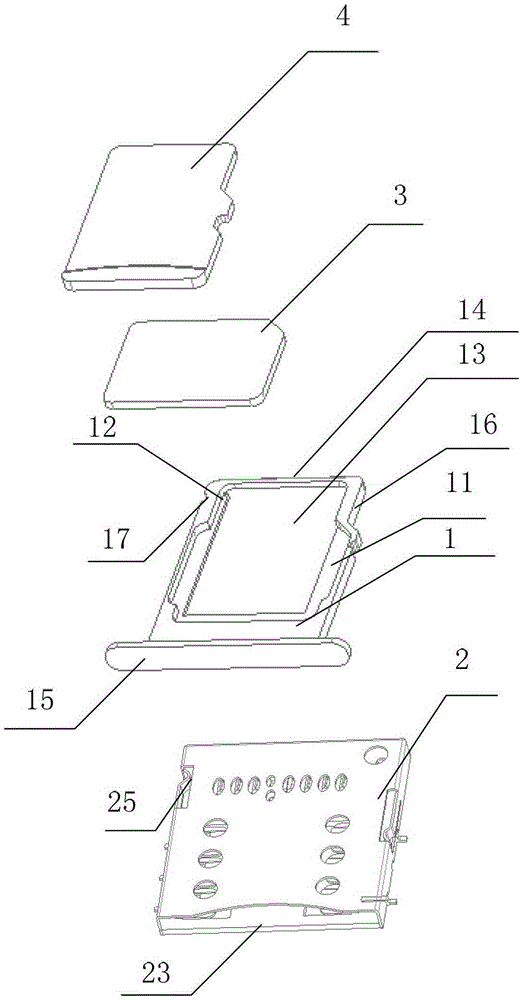

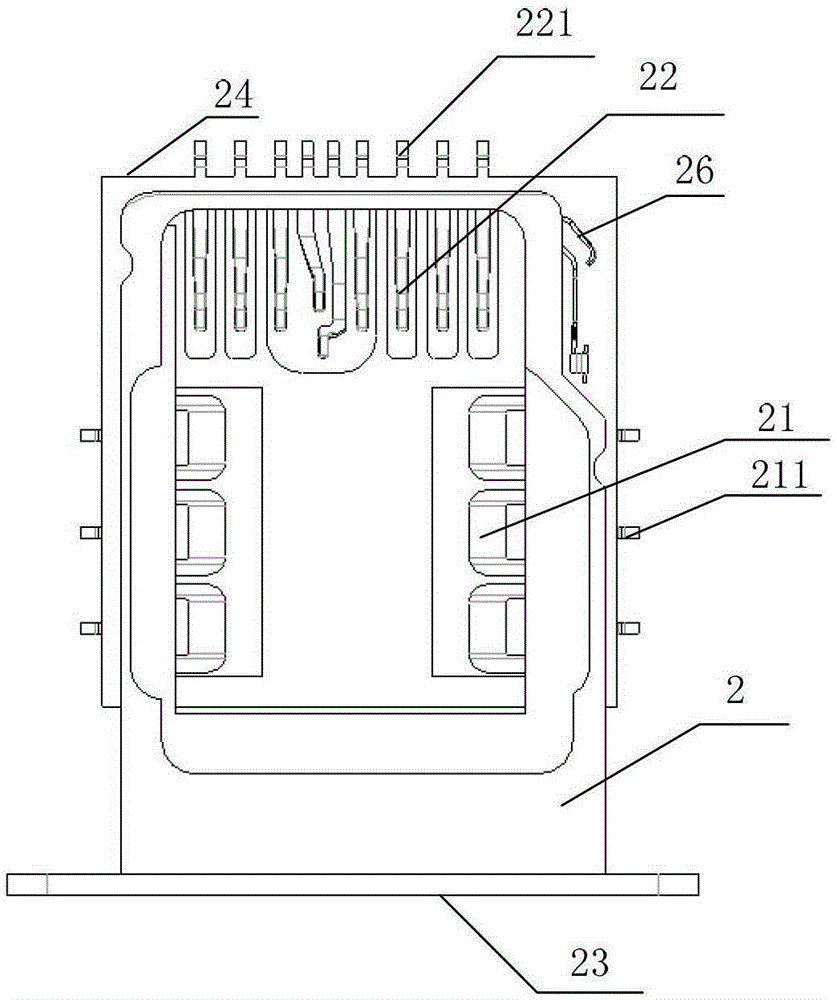

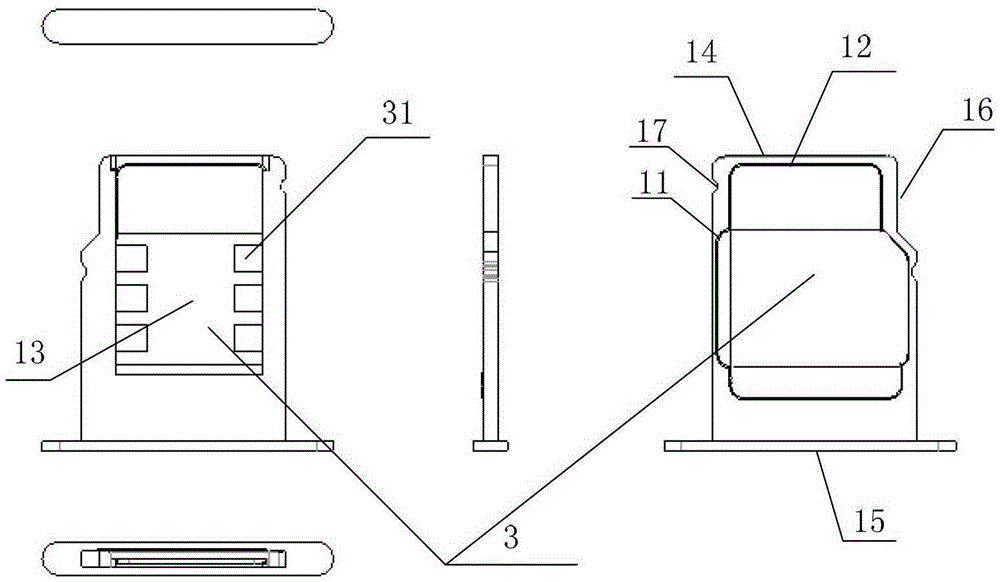

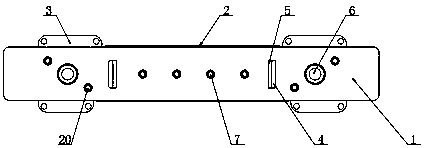

Digital card holder

ActiveCN103367951BSmall footprintMeet different card usage needsConveying record carriersDigital data processing detailsSoftware engineeringEngineering

The embodiment of the present invention discloses a digital card fixing device, comprising: a tray and a deck; the tray includes: a first groove for accommodating the first digital card; a second groove, perpendicular to the first groove It is set for accommodating the second digital card; the first groove and the second groove have partially overlapped hollow parts; the deck includes: a first elastic piece and a second elastic piece; wherein, when the tray is inserted into the deck, the second An elastic piece and a second elastic piece are exposed from the hollow part; when the first digital card is placed in the first groove, the first elastic piece is in contact with the metal contact of the first digital card; when the second digital card is placed in the second When the groove is inserted, the second elastic piece is in contact with the metal contact of the second digital card. The embodiment of the present invention implements a digital card fixing device compatible with SIM cards and SD cards. On the premise of not increasing the layout space, a digital card fixing device can flexibly meet different card usage requirements of users.

Owner:HUAWEI DEVICE CO LTD

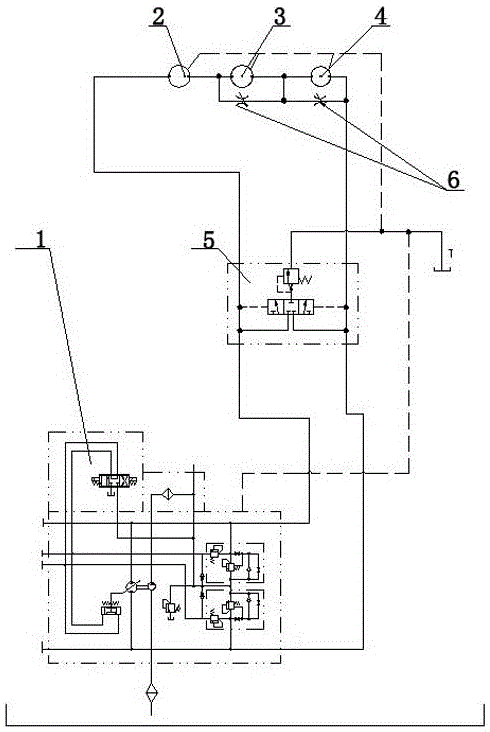

A channel device hydraulic control system for sugarcane harvester

InactiveCN104154063BAvoid congestionReduce connection spaceHarvestersServomotorsHydraulic motorCarrying capacity

Owner:HENAN UNIV OF SCI & TECH

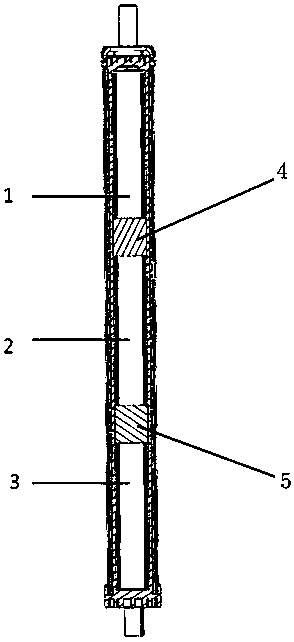

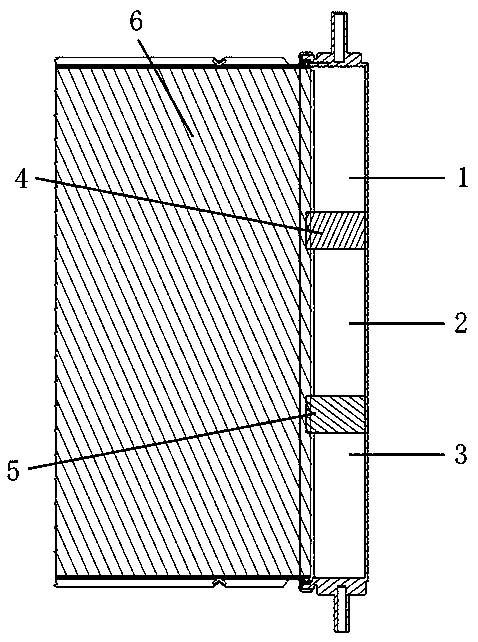

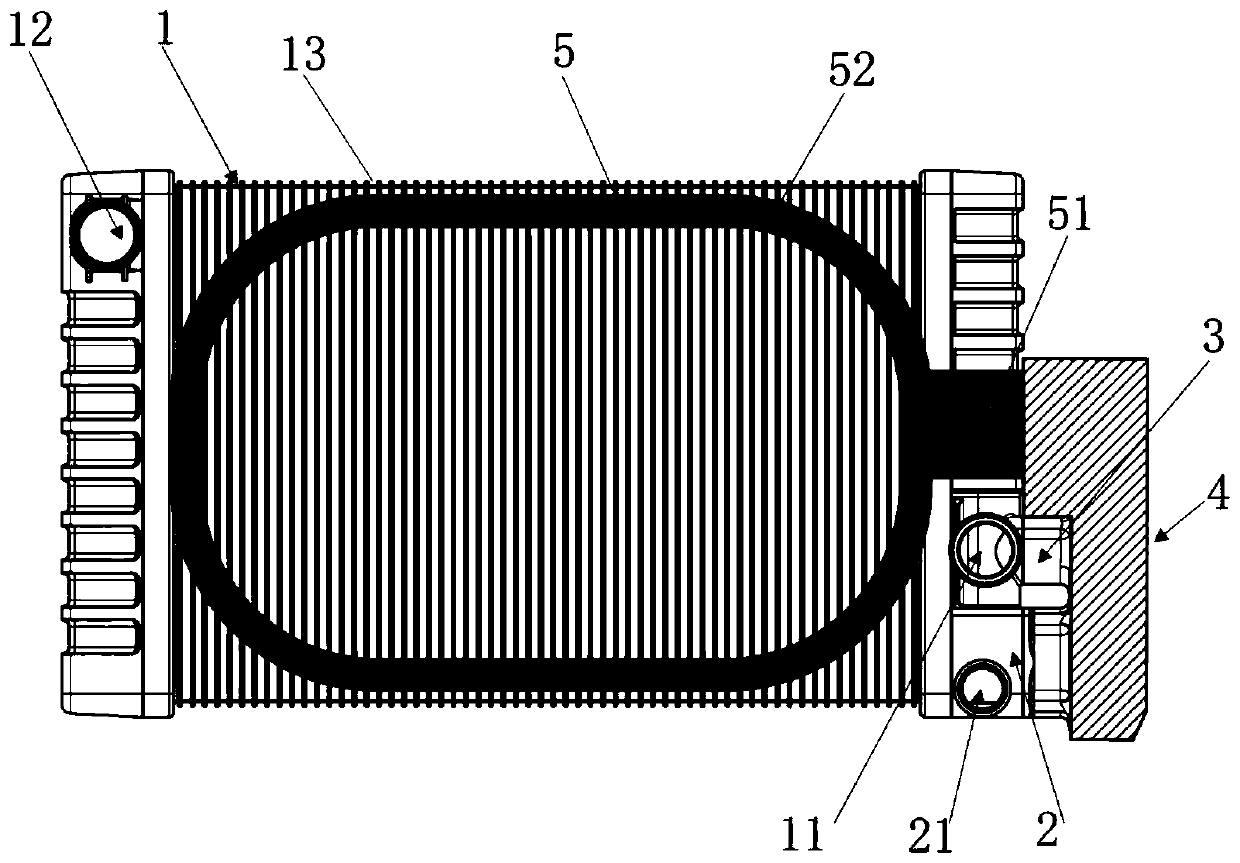

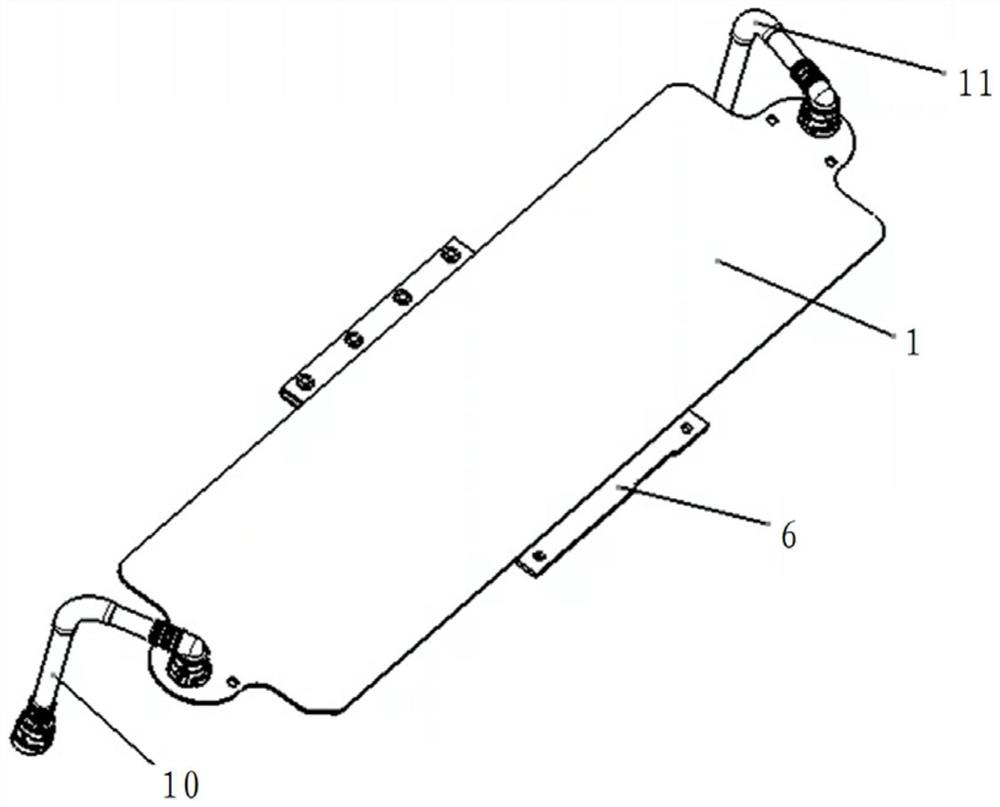

Self-adjusting composite radiator

InactiveCN109595066ASave layout spaceOptimize usage efficiencyCoolant flow controlMachines/enginesDeuteron radiationHeat spreader

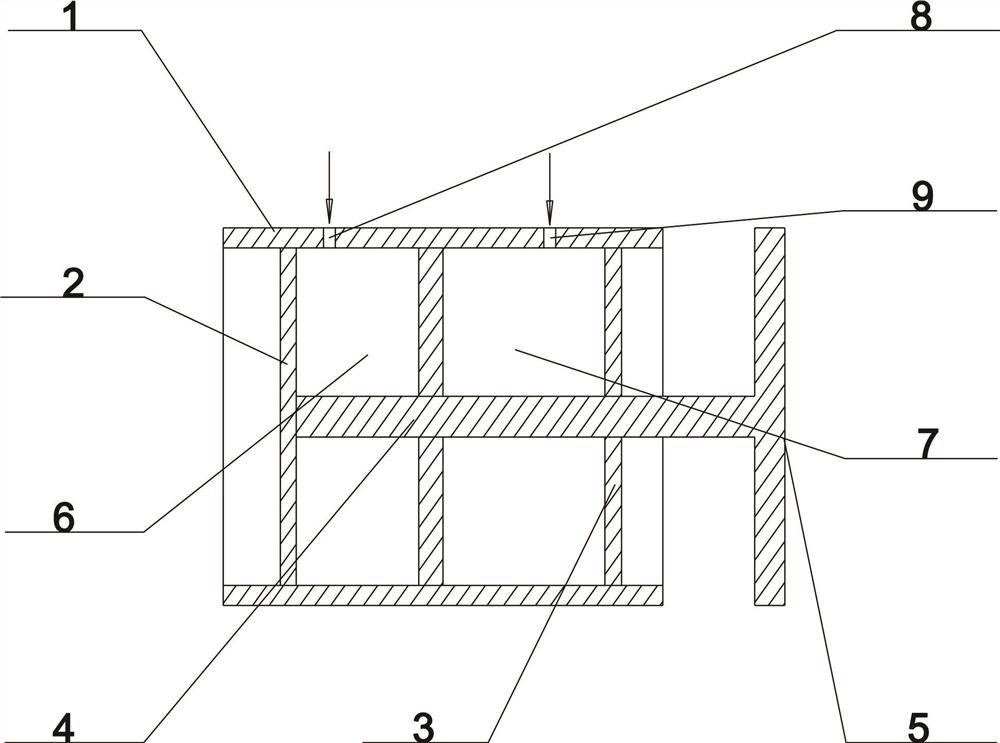

The invention discloses a self-adjusting composite radiator. The self-adjusting composite radiator comprises a first radiator water chamber (1), a second radiator water chamber (2), a third radiator water chamber (3), a radiator water chamber upper separator (4) and a radiator water chamber lower separator (5); the radiator water chamber upper separator is arranged between the first radiator waterchamber and the second radiator water chamber, and the radiator water chamber lower separator is arranged between the second radiator water chamber and the third radiator water chamber; the radiatorwater chamber upper separator and the radiator water chamber lower separator are externally connected with a temperature control device, and after the temperature control device controls the upper partition of the radiator water chamber to be opened, the first radiator water chamber and the second radiator water chamber are combined; and after the temperature control device controls the water chamber of the radiator to be opened, the water chamber of the second radiator and the water chamber of the third radiator are combined. The heat dissipation area of the radiator can be adjusted accordingto heat dissipation requirements, and thus the purpose of fully utilizing the heat dissipation area is achieved, and the arrangement space and the cost are reduced.

Owner:SAIC MOTOR

True wireless Bluetooth earphone antenna structure and true wireless Bluetooth earphone

PendingCN110324739AReduce overall layout spaceLow efficiencyMicrophonesLoudspeakersCommunication qualityEngineering

The invention relates to the technical field of communication, in particular to a true wireless Bluetooth headset antenna structure and a true wireless Bluetooth headset. The structure comprises a battery, a PCB and a feed-in part. The feed-in part is arranged between the battery and the PCB. One end of the feed-in part is connected to the PCB, and the other end of the feed-in part is connected to the battery in a feed-in mode. The battery is a radiation part of an antenna structure, and the battery, the feed-in part and the grounding end form the antenna structure. According to the antenna structure, the battery is fed into the feed-in part, and the battery is integrated into the radiation part of the antenna structure, so that the use space of the antenna structure in the earphone is saved, and the problem that the communication quality of the antenna in the earphone is influenced due to space shape limitation is solved.

Owner:TYMPHANY ACOUSTIC TECH (HUIZHOU) CO LTD

Automobile anti-collision beam structure based on bionic design

InactiveCN111547137ASimplify the installation processReduce connections and layout of spaceUnderstructuresEnergy absorptionMechanical engineering

The invention discloses an automobile anti-collision beam structure based on bionic design, and particularly relates to the field of automobile anti-collision beams. The automobile anti-collision beamstructure comprises a cross beam body, the cross beam body is in an arc shape, a second cell-shaped groove is formed in the cross beam body in the length direction, energy absorption boxes are fixedly installed at the two ends of one side of the cross beam body in the transverse direction respectively, and a reinforcing assembly is fixedly installed on the portion, between the two energy absorption boxes, of the cross beam body. The energy absorption box comprises screws inserted into the two transverse ends of the cross beam body, energy absorption sleeve bases are fixedly installed at the ends, close to the reinforcing assemblies, of the screws, the ends, close to the energy absorption sleeve bases, of the outer surfaces of the screws are sleeved with reinforcing pieces, and nuts are fixedly arranged at the ends of one ends of the screws. The anti-collision beam has a high-strength structure and also has the effect of rapidly transmitting, decomposing and absorbing collision energy,the installation process is simplified, connection between parts and arrangement of space are reduced, the assembly complexity is reduced, and the lightweight design of the anti-collision beam is achieved.

Owner:丹阳市车船装饰件有限公司

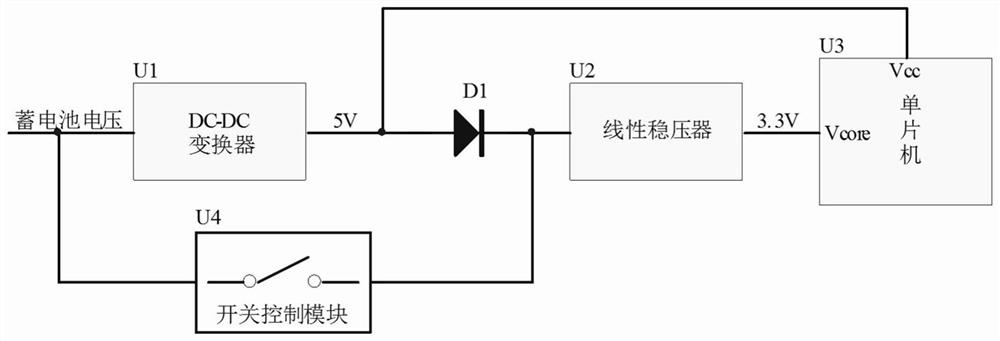

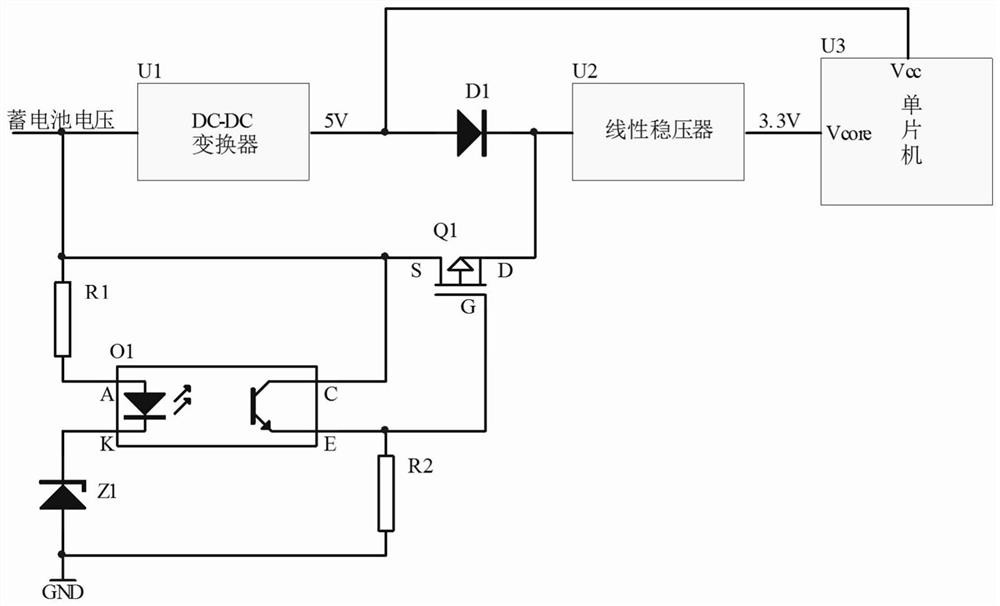

A power supply module for expanding the working power range of the diesel engine electronic control system

ActiveCN111049218BReduce overall layout spaceLow costBatteries circuit arrangementsVolume/mass flow measurementElectronic control systemEngineering

The present invention provides a power supply module for expanding the working power range of a diesel engine electronic control system, including a DC-DC converter U1, a linear voltage regulator U2, a single-chip microcomputer U3, an anti-current backflow diode D1 and a switch control module. The DC converter U1, the anti-current backflow diode D1, the linear voltage regulator U2 and the core power supply terminal Vcore of the single-chip microcomputer U3 are sequentially connected, and the output terminal of the DC-DC converter U1 is also connected to the interface power supply terminal Vcc of the single-chip microcomputer U3; Both the DC-DC converter U1 and the input terminals of the switch control module are connected to the battery voltage. The invention adds a switch control module on the basis of the traditional power supply technology to realize the expansion of the working power supply range, has few components, low cost, hardly increases the layout space of components, and has strong implementability and popularization.

Owner:CHINA NORTH ENGINE INST TIANJIN

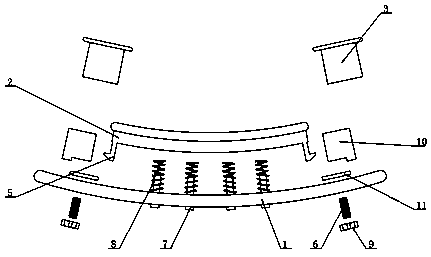

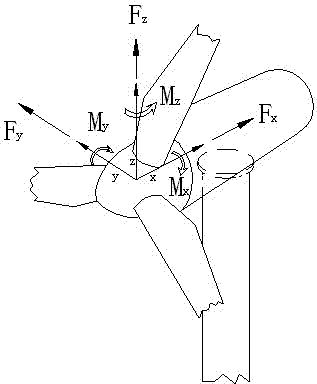

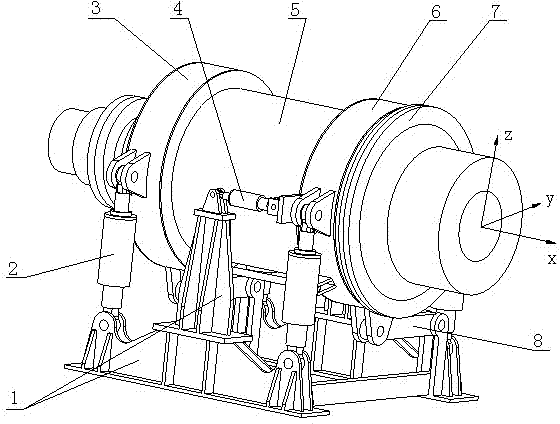

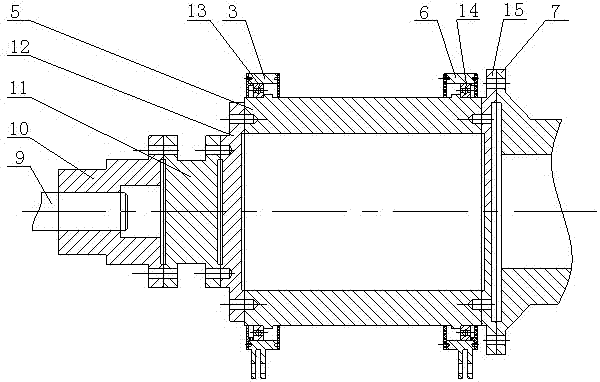

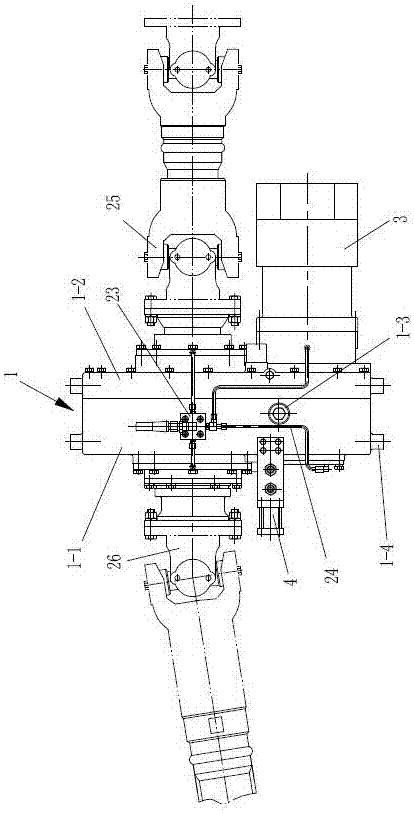

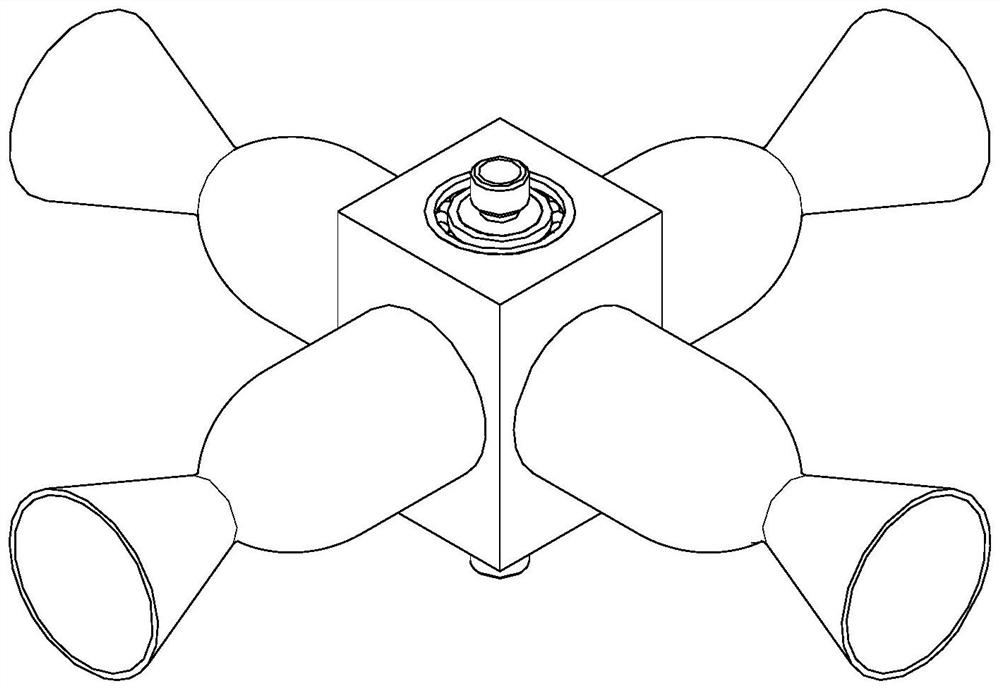

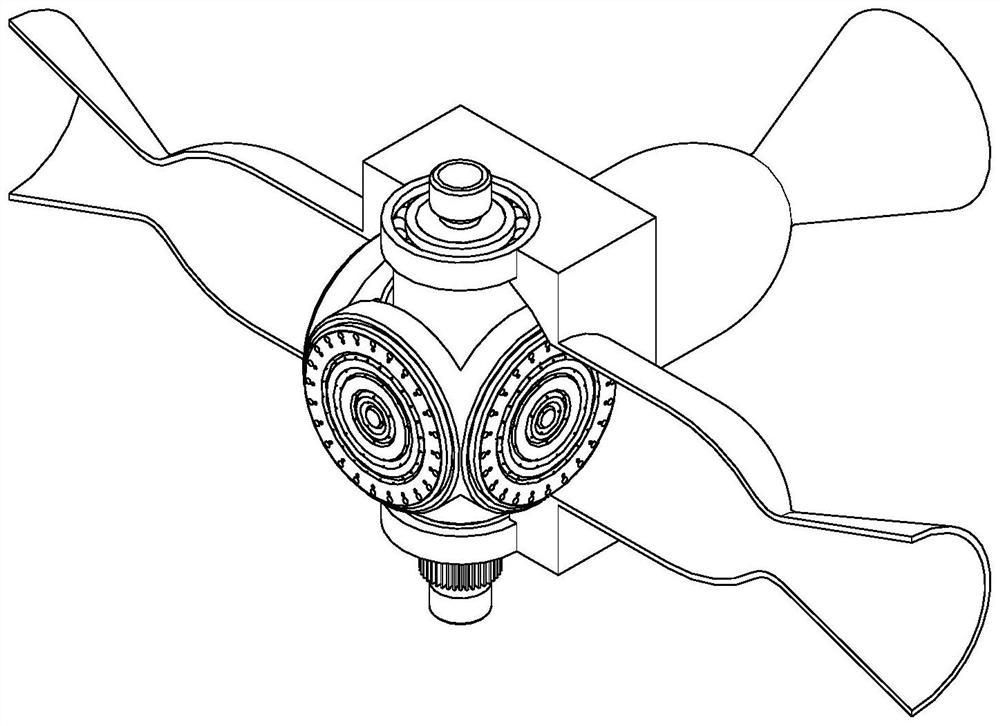

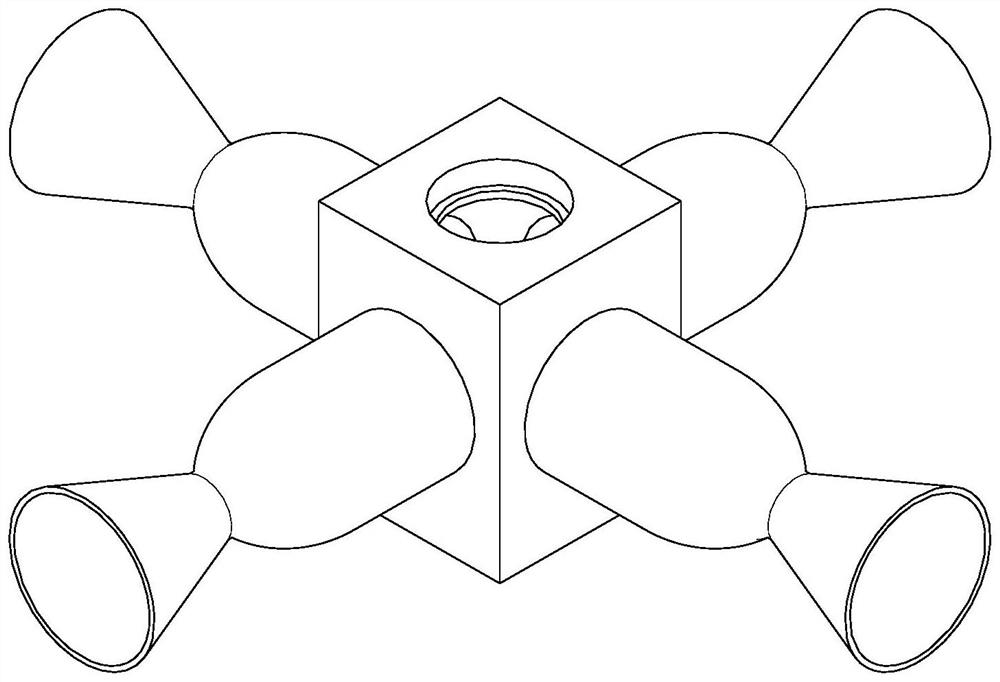

Loading simulation device for test bed of wind turbine

The invention discloses a loading simulation device for a test bed of a wind turbine. A driving shaft is connected with a flange and a mainshaft flange of the wind turbine by a single-flange flexible shaft coupler, a torque sensor, a flange and a loading shaft; two ends of the loading shaft are supported in the bearing seat respectively; one end of each of four vertical dual-action oil cylinders is connected with a base; the other end of each of the four vertical dual-action oil cylinders is symmetrically connected at two sides of a loading bearing seat respectively; one end of each of two axial dual-action oil cylinders is connected with the base respectively; the other end of each of the two axial dual-action oil cylinders is connected with the loading bearing seat close to the mainshaft flange end of the wind turbine mainshaft; one end of each of two connecting rods is connected on the base; and the other end of each of the two connecting rods is connected with the lower part of each of the two loading bearing seats. The loading simulation device can be used for simulating various loads under practical running conditions of the wind turbine; the oil cylinder in only one direction is arranged in radial plane; the vertical force is converted into horizontal force by the connecting rods, thus realizing the loading of any radial forces; the loading simulation device has a simple and compact structure, has the advantages of reducing the arrangement space and cost, and can be controlled conveniently.

Owner:ZHEJIANG UNIV

Automobile thermal management intelligent radiator module and automobile

PendingCN111516554AIncrease air flowReduce overall layout spaceMultiple way valvesElectric vehicle charging technologyHeat managementControl theory

The invention relates to an automobile thermal management intelligent radiator module and an automobile. The automobile thermal management intelligent radiator module comprises a radiator, an electronic water pump, an electronic ball valve, an airflow generator, and a domain controller; the radiator comprises a housing with a flow channel, and a main water inlet and a main water outlet which are disposed on the housing and are communicated with the flow channel; the electronic water pump and the radiator are integrally arranged; the electronic water pump is provided with a first water inlet close to the main water inlet and a first water outlet communicated with the housing; the electronic ball valve and the radiator are integrally arranged; the electronic ball valve comprises at least onevalve body; the at least one valve body is arranged at the main water inlet so as to adjust flow flowing to the flow channel from the main water inlet; the airflow generator is connected with the radiator and used for increasing the air flow of the radiator; and the domain controller is in signal connection with the electronic water pump, the electronic ball valve and the airflow generator. The electronic water pump, the electronic ball valve and the radiator are integrated, so that the overall arrangement space and pipeline arrangement of the automobile thermal management intelligent radiator module are reduced; and the air flow generator connected with the radiator is arranged and used for increasing the air flow of the radiator.

Owner:苏州玲珑汽车科技有限公司

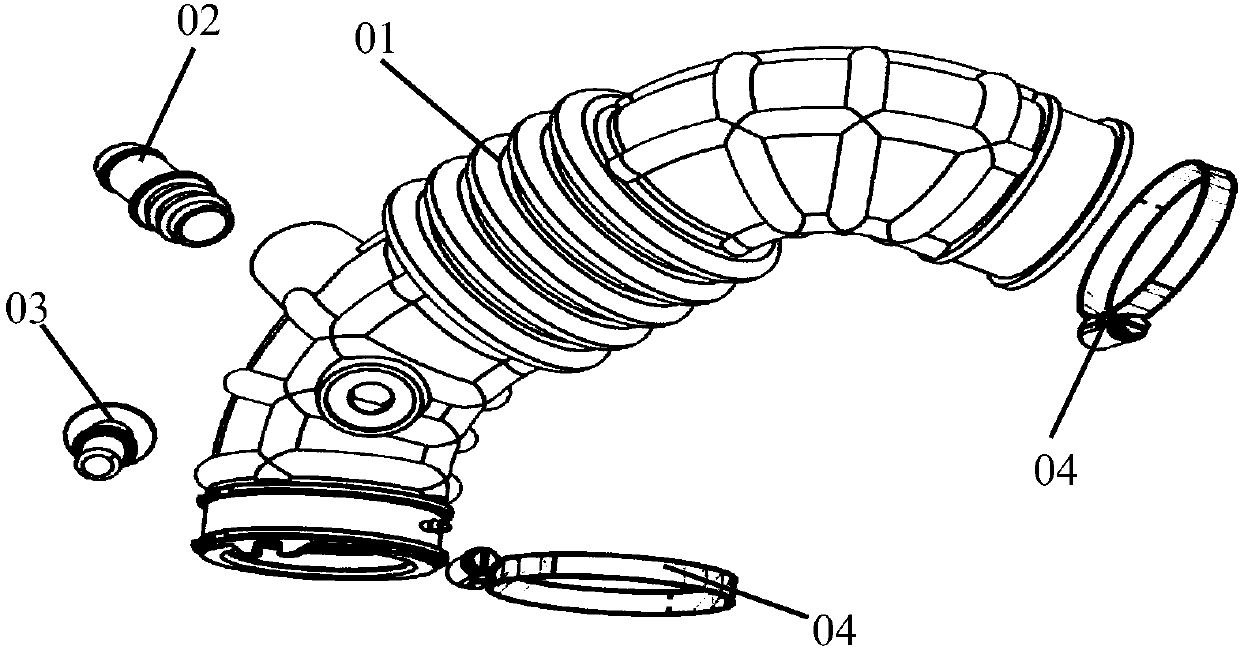

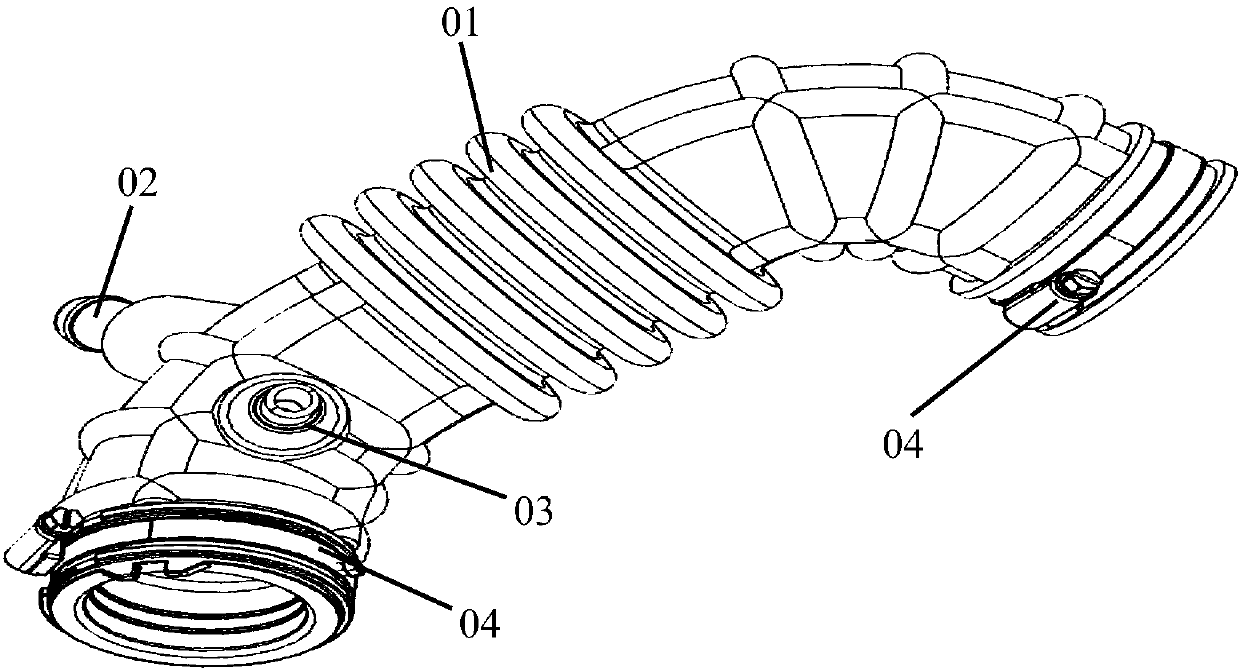

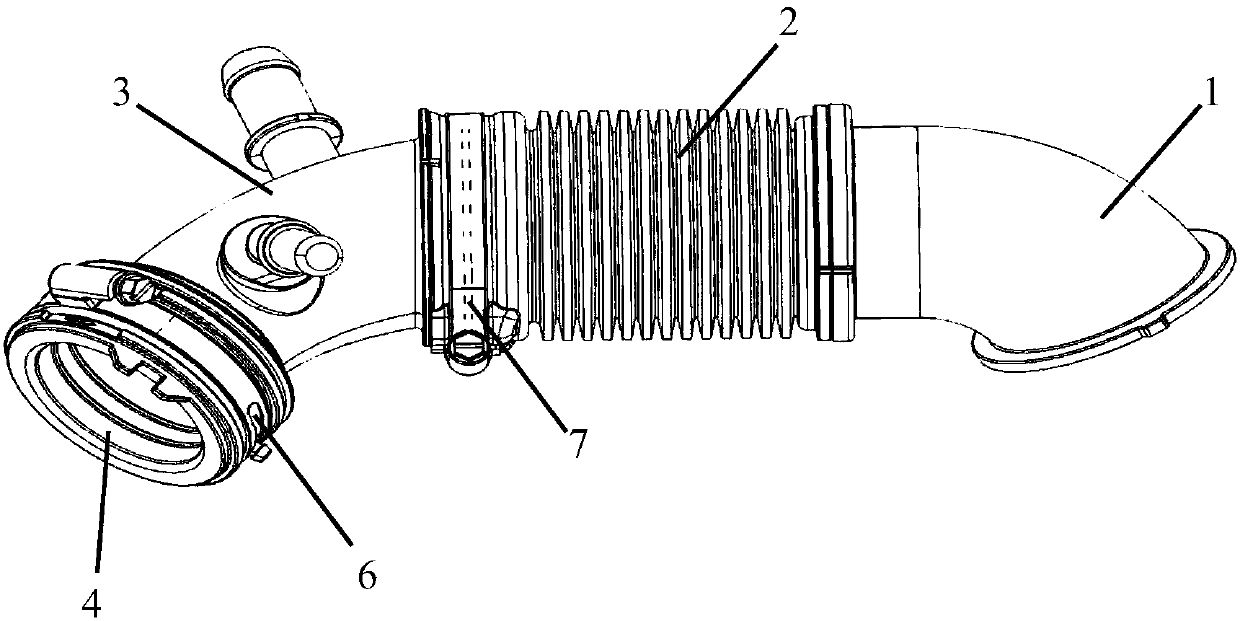

Air filter air outlet pipe

PendingCN110529308APlay the role of vibration isolationSimple preparation processCombustion-air/fuel-air treatmentMachines/enginesElastomerAir filter

The invention discloses an air filter air outlet pipe. The air filter air outlet pipe comprises a first air filter air outlet pipe, a third air filter air outlet pipe, a rubber sleeve and a second airfilter air outlet pipe made of an elastomer material, at least three circles of ripples are annularly arranged on the second air filter air outlet pipe, and the left end part of the first air filterair outlet pipe is fixedly connected with the right end part of the second air filter air outlet pipe. The left end part of the second air filter air outlet pipe is detachably and fixedly connected with the right end part of the third air filter air outlet pipe, the left end of the third air filter air outlet pipe is detachably connected with the right end of the rubber sleeve in an inserted mode,the right end of the first air filter air outlet pipe is fixedly connected with the air filter upper shell, and the left end of the rubber sleeve is detachably and fixedly connected with an engine connector in a sealed mode. According to the air filter air outlet pipe, the usage amount of the rubber hose is reduced, the part cost is reduced, the sealing performance is improved, the arrangement space is small, the interference between the air filter air outlet pipe and the peripheral parts is avoided, the abrasion risks are eliminated, the manufacturing process is simple, the manufacturing errors are reduced, and the vibration isolation performance is improved.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

power transmission box

ActiveCN103671805BImprove machining accuracyGuaranteed coaxialityGearboxesGearing controlHydraulic motorBall bearing

The invention discloses a power transmission case comprising a case body, an input shaft, an output shaft, a driving gear, a driven gear, a shift clutch, a toggle mechanism and a hydraulic motor. The case body comprises left case body and a right case body, subdivision surfaces of the left case body and the right case body are vertical planes, a bearing seat and an internal spline are arranged in a gear hole of the driving gear, two ball bearings are mounted in the bearing seat, the input shaft is provided with an external spline, the shift clutch is composed of a shift meshing sleeve, a meshing sleeve positioning mechanism and the internal spline of the driving gear, the meshing sleeve positioning mechanism is mounted on the input shaft, the shift meshing sleeve is provided with an internal spline and an external spline, the internal spline of the shift meshing sleeve is meshed with and in axial sliding fit with the external spline of the input shaft, the external spline of the shift meshing sleeve can be meshed with or separated from the internal spline of the driving gear, and the toggle mechanism comprises a toggle cylinder, a fork pull rod and a fork. The power transmission case is simple and reasonable in structure and easy to manufacture, the requirements for high-speed running and low-constant speed operating, running and driving of a rapid multifunctional operating vehicle are met.

Owner:CHANGZHOU RUITAI ENG MASCH CO LTD +1

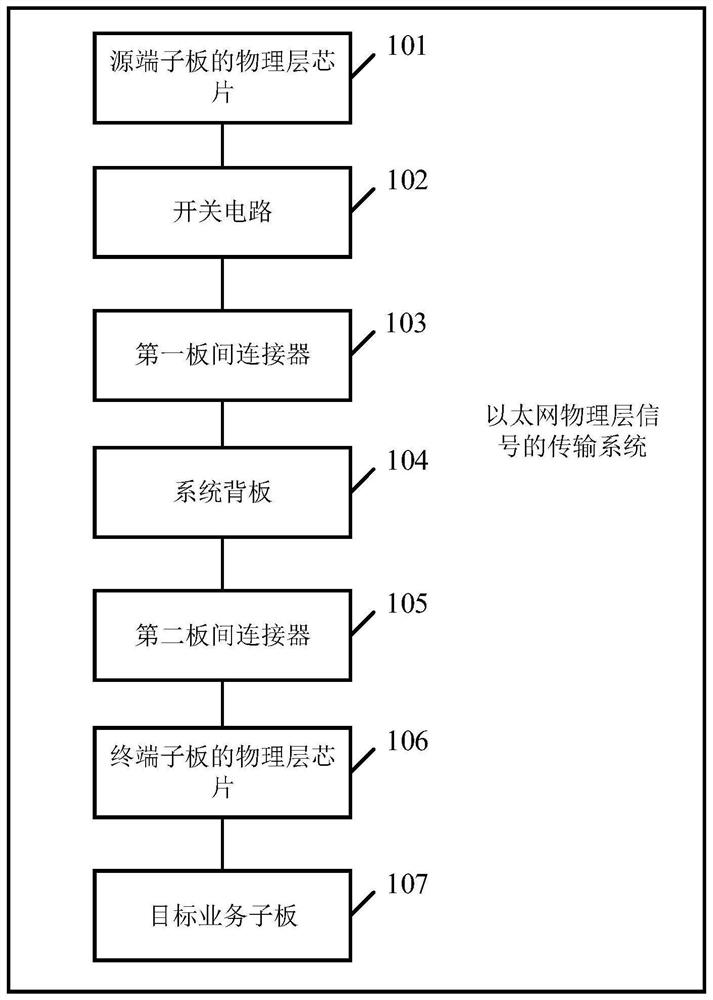

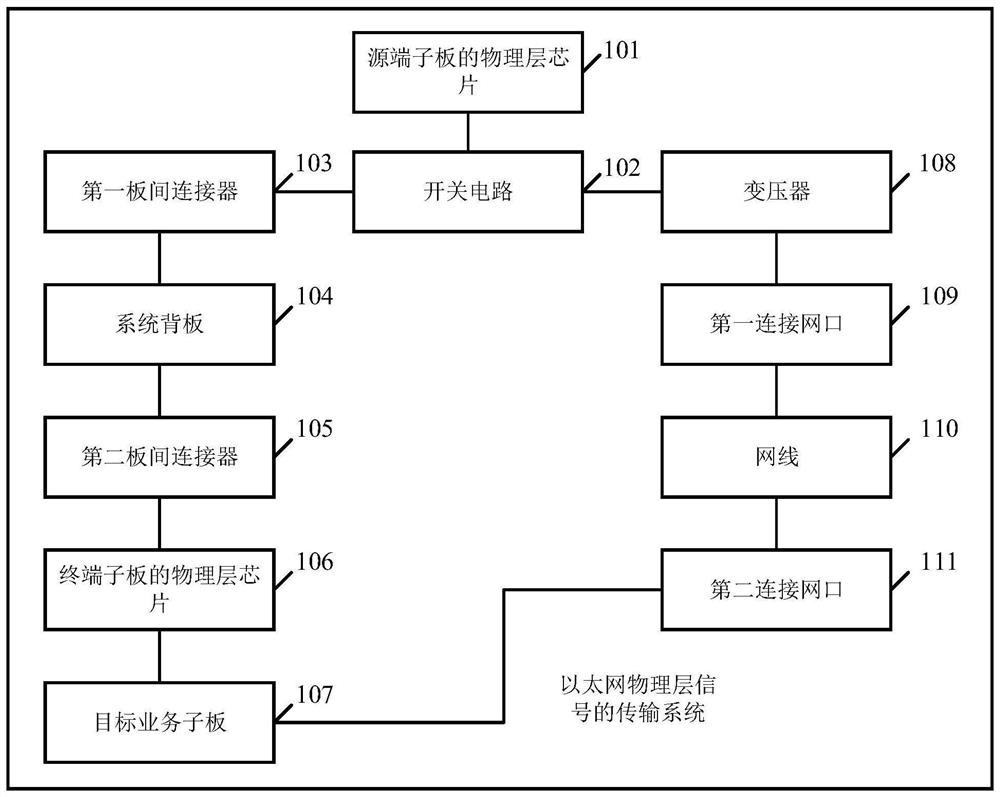

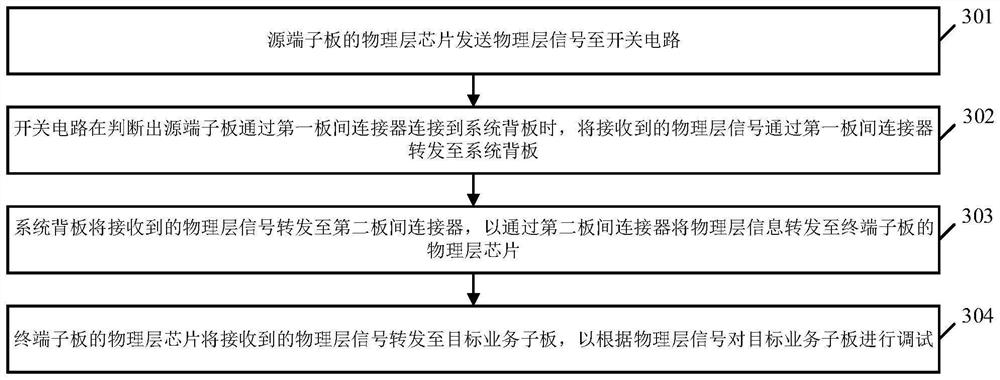

A transmission system and signal transmission method of an Ethernet physical layer signal

ActiveCN111131087BReduce overall layout spaceLow implementation costData switching networksPhysical layerEngineering

The embodiment of the present invention relates to the technical field of Ethernet, and more specifically, relates to a transmission system and a signal transmission method of Ethernet physical layer signals, the physical layer chip of the source terminal board included in the system is used to send the physical layer signal to the switch circuit ; When the switch circuit judges that the source terminal board is connected to the system backplane through the first inter-board connector, the received physical layer signal is forwarded to the system backplane through the first inter-board connector; The physical layer signal is forwarded to the second inter-board connector, so that the physical layer information is forwarded to the physical layer chip of the terminal sub-board through the second inter-board connector; the physical layer chip of the terminal sub-board forwards the received physical layer signal to The target service sub-board is used to debug the target service sub-board according to the physical layer signal. The embodiment of the present invention can reduce the implementation cost of the Ethernet system architecture.

Owner:GUANGDONG VTRON TECH CO LTD

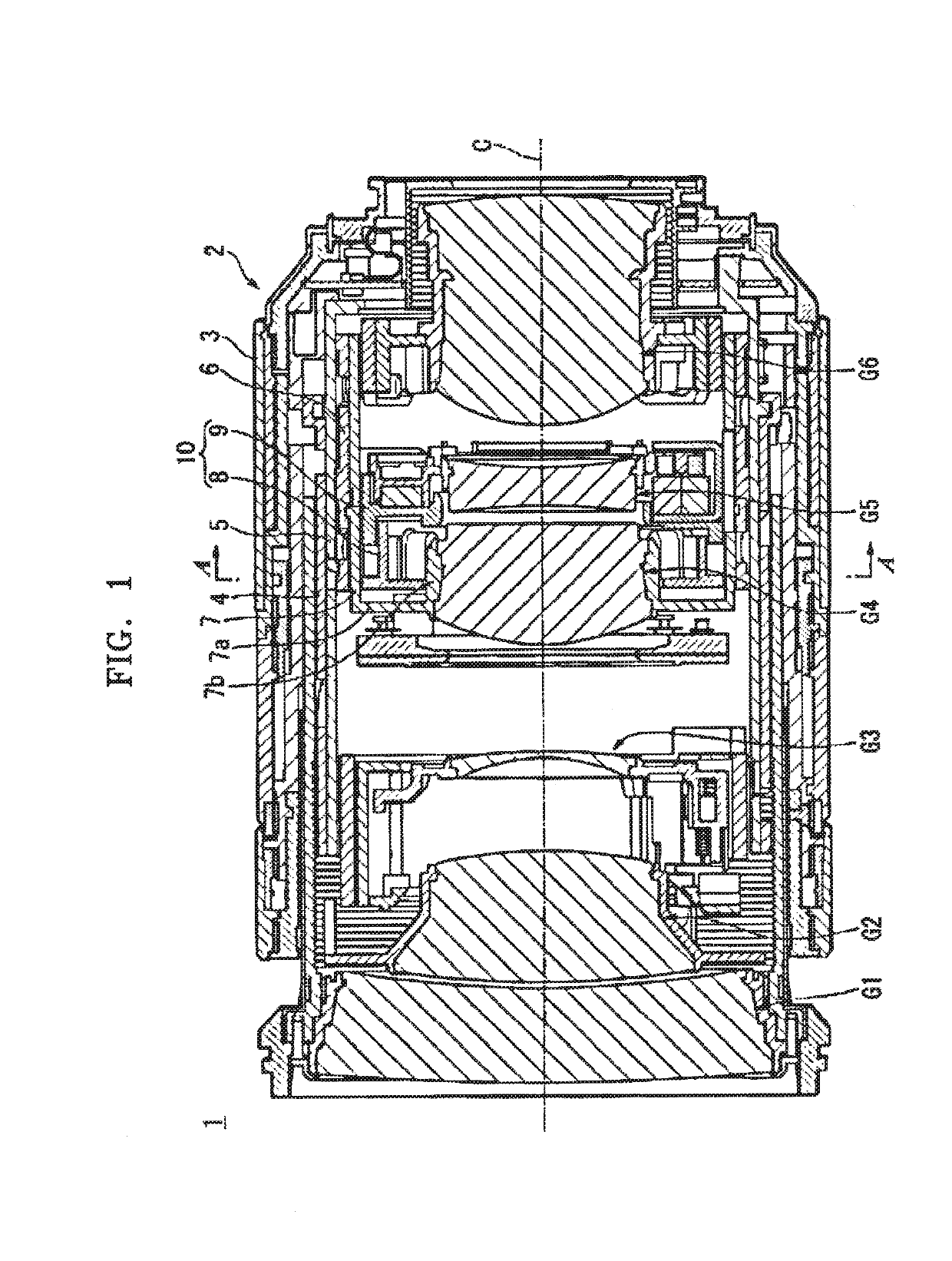

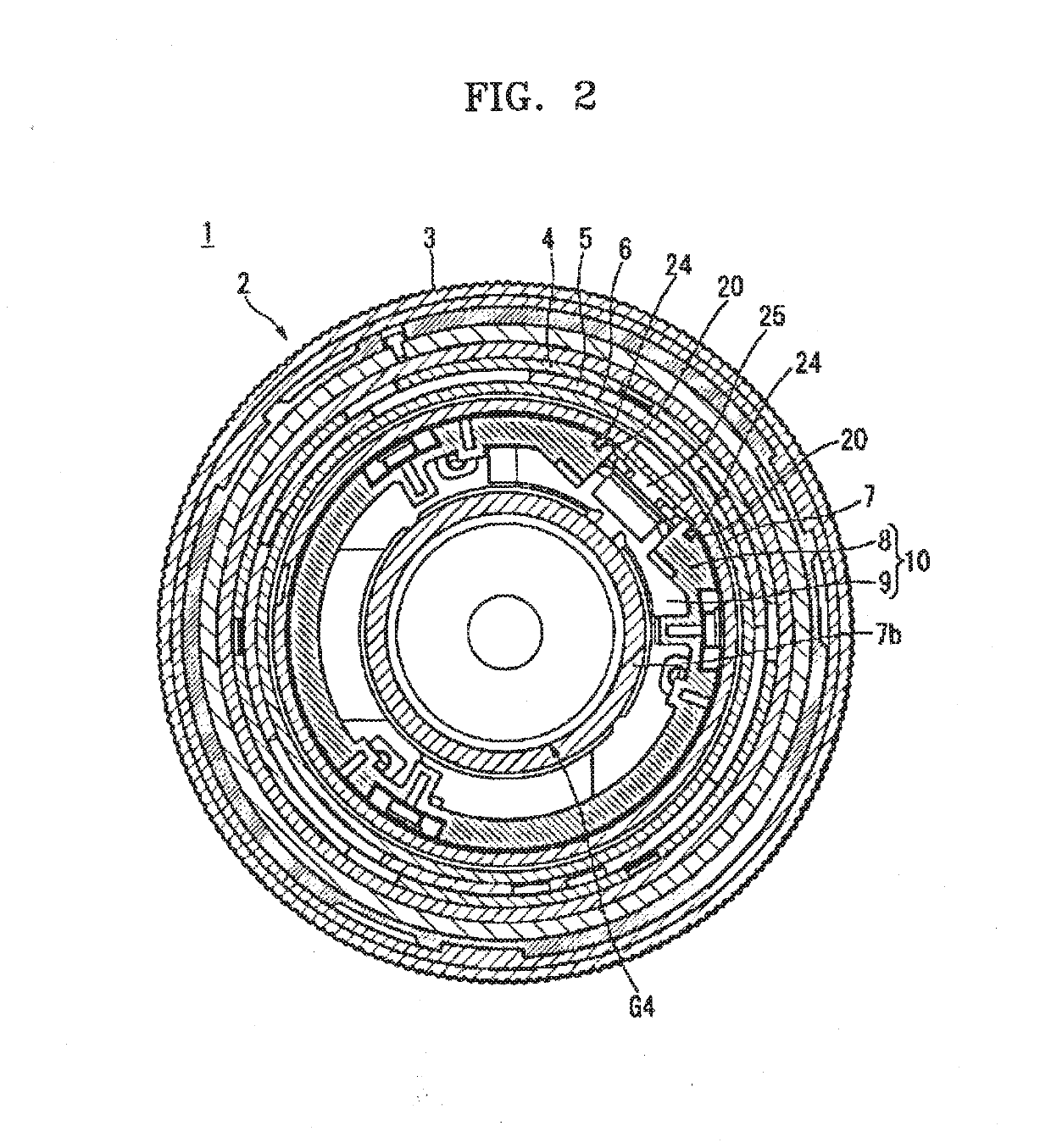

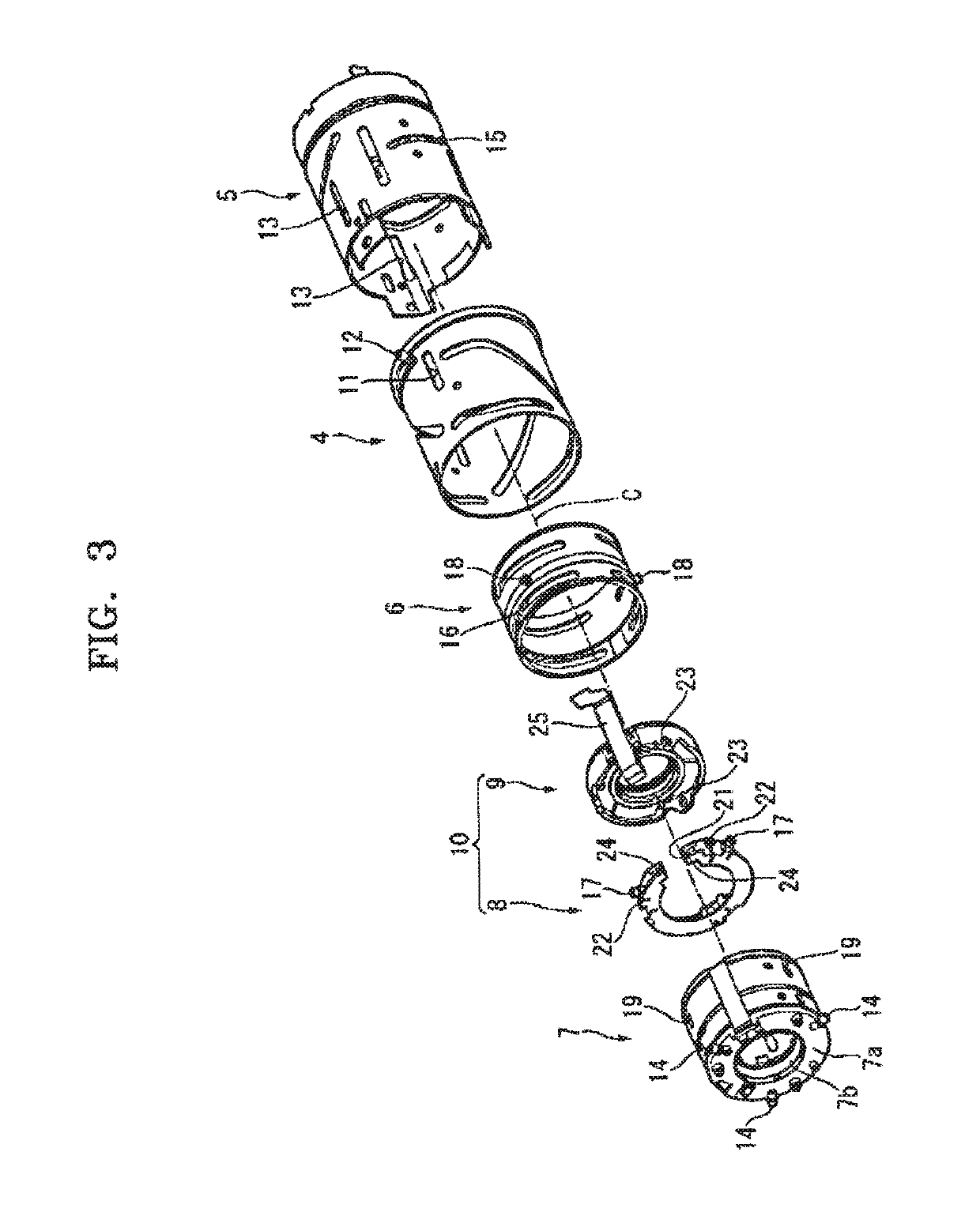

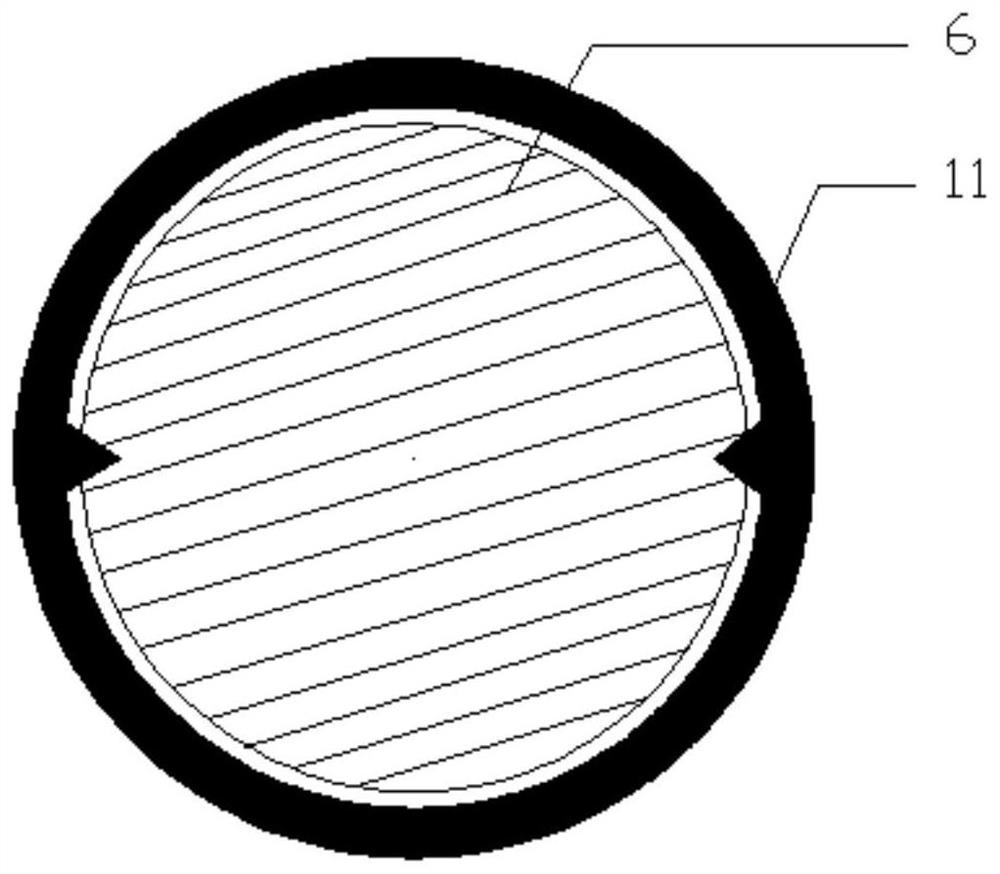

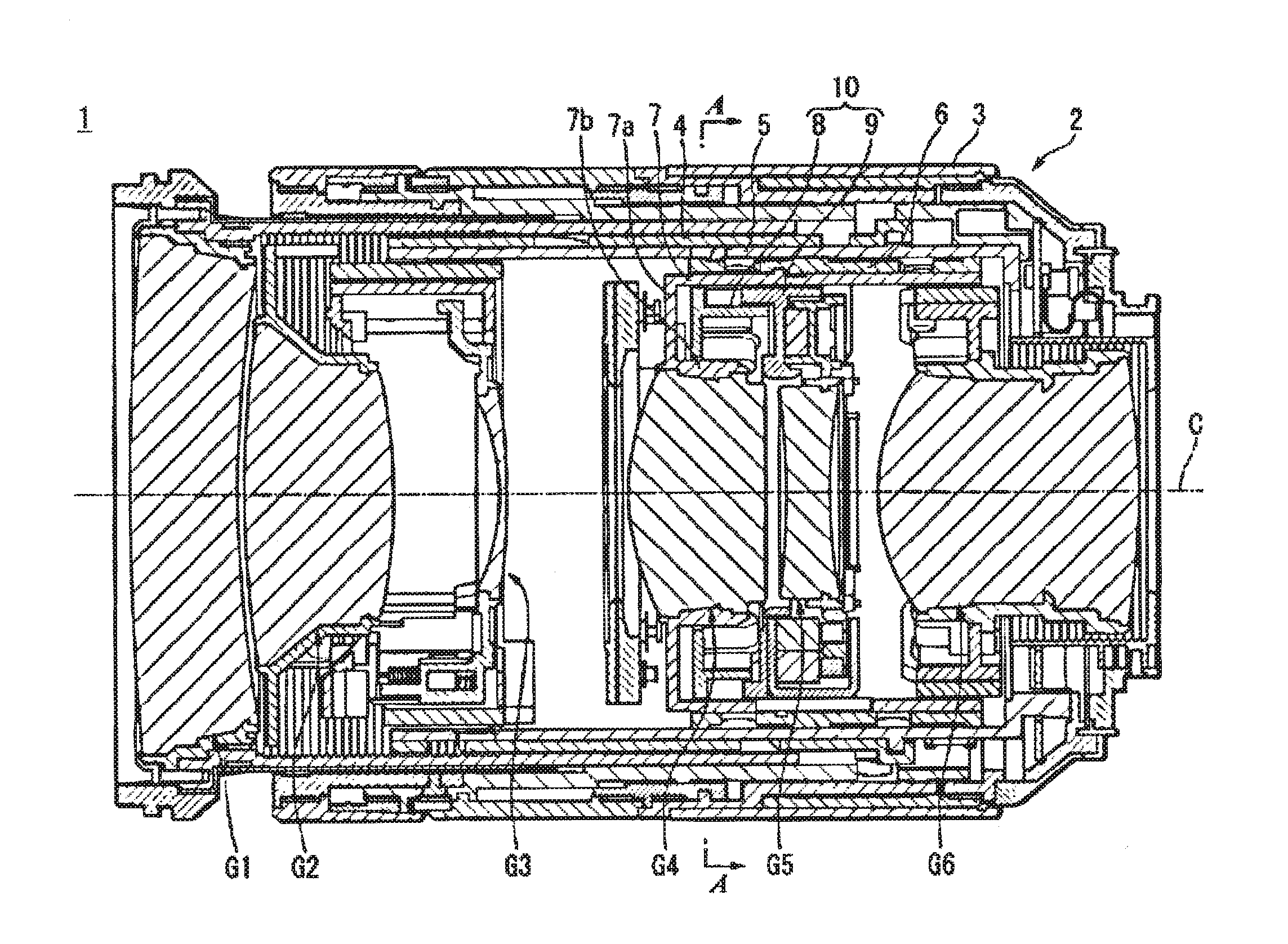

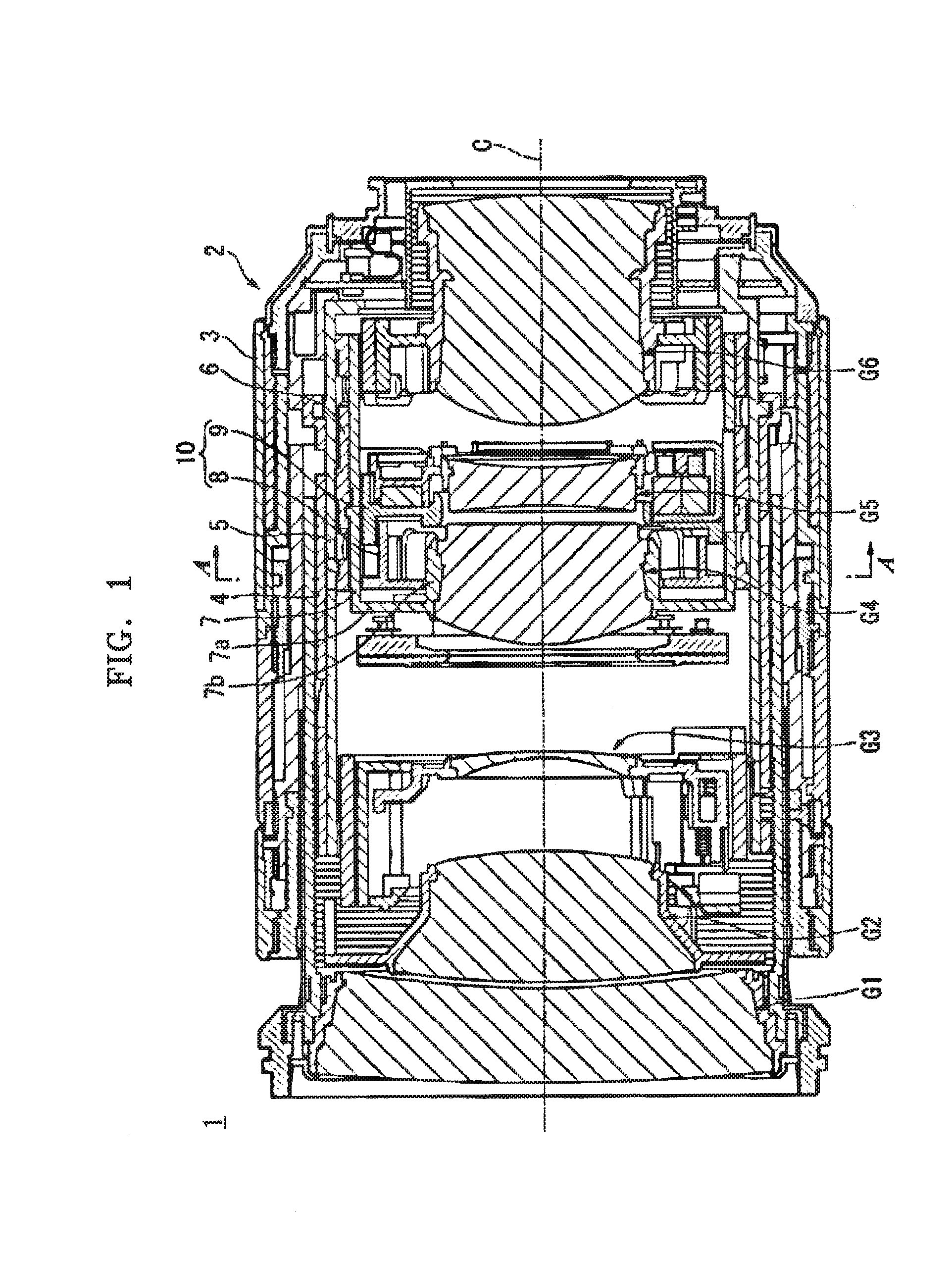

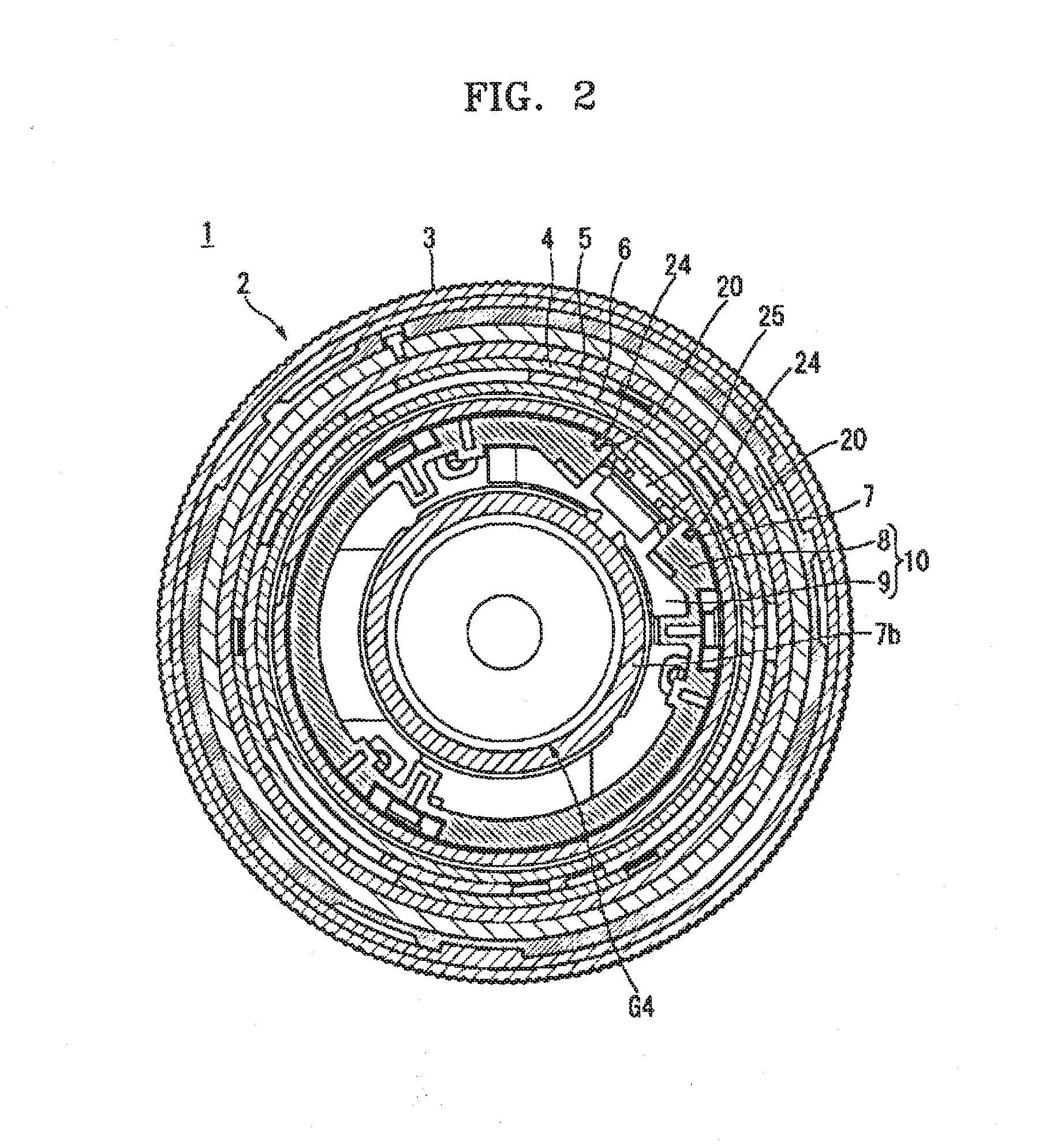

Lens barrel and optical apparatus

A lens barrel having a reduced size and a related optical apparatus is disclosed. The lens barrel includes a cylindrical fixed frame and a cylindrical movable frame. The cylindrical first frame includes an outer wall extending around the optical axis and a cylindrical second frame is inserted thereto the first frame. The first frame includes a notch having first assembly portions at both side portions. The second frame includes second assembly portions that are assembled to be fixed to the first assembly portions.

Owner:SAMSUNG ELECTRONICS CO LTD

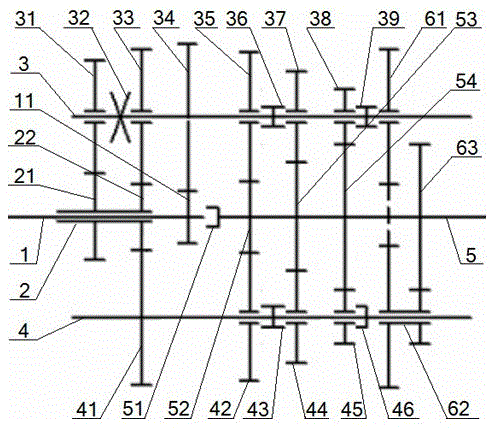

Structure and gear shifting method of a solid-shaft synchronous double-countershaft transmission

ActiveCN103821883BShorten the lengthImprove mechanical propertiesToothed gearingsGearing detailsEngineeringMechanical engineering

The invention discloses a dual-countershaft transmission structure with a synchronous solid shaft and a shifting method of the dual-countershaft transmission structure. The dual-countershaft transmission structure comprises a solid input shaft and a hollow input shaft, wherein the solid input shaft is in transmission matching with an output shaft through an odd-gear countershaft, the hollow input shaft is in transmission matching with the output shaft through an even-gear countershaft, the solid input shaft is sequentially sleeved with a solid shaft fixed connecting synchronous gear and a solid shaft fixed connecting gear from the first end to the tail end, the solid shaft fixed connecting gear is respectively meshed with an odd-gear countershaft fixed connecting gear and an even-gear countershaft hollow sleeve gear, the solid shaft fixed connecting synchronous gear is meshed with an even-gear countershaft hollow sleeve synchronous gear, the even-gear countershaft is respectively in transmission matching with the even-gear countershaft hollow sleeve synchronous gear and the even-gear countershaft hollow sleeve gear through a synchronous friction wheel, and the even-gear countershaft fixed connecting gear is meshed with a hollow shaft fixed connecting gear on the hollow input shaft. According to the dual-countershaft transmission structure disclosed by the invention, the structure is simple, the arrangement space is small, the maintenance is convenient, and the production cost is low.

Owner:DONGFENG COMML VEHICLE CO LTD

A hollow shaft synchronous double countershaft transmission structure and its shifting method

ActiveCN103821882BShorten the lengthImprove mechanical propertiesToothed gearingsGearing controlMedial axisGear wheel

The invention relates to a double middle shaft transmission structure with hollow shaft synchronism and a shifting method thereof. The structure comprises a solid input shaft and a hollow input shaft, wherein the solid input shaft is in transmission matching with an output shaft through an odd-shift middle shaft, the hollow input shaft is in transmission matching with an output shaft through an even-shift middle shaft, the hollow input shaft is sequentially sheathed with a fixing connecting synchronous gear of the hollow shaft and a fixing connecting gear of the hollow shaft from front end to tail end, the fixing connecting gear of the hollow shaft is respectively engaged with a hollow sheath synchronous gear of the odd-shift middle shaft and a fixing connecting gear of the even-shift middle shaft, the fixing connecting synchronous gear of the hollow shaft is engaged with the hollow sheath synchronous gear of the odd-shift middle shaft, the odd-shift middle shift is respectively in transmission matching with the hollow sheath synchronous gear of the odd-shift middle shaft and the hollow sheath gear of the odd-shift middle shaft through synchronous friction wheels, the fixing connecting gear of the odd-shift middle shaft is engaged with the fixing connecting gear of the solid input shaft, and the fixing connecting gear of the solid input shaft is sheathed on the solid input shaft. The structure has the advantages that the structure is simple, the arrangement space is little, the overhauling is convenient, and the production cost is low.

Owner:DONGFENG COMML VEHICLE CO LTD

Fault-tolerant steering-by-wire device and control method thereof

ActiveCN110949492BEnsure safetyAchieve mechanical connectionSteering linkagesMechanical steeringSteering wheelSteering column

The invention provides a steering-by-wire fault-tolerant device and its control method. The fault-tolerant device includes a signal acquisition unit, an electronic control unit and an actuator. The control unit and the electronic control unit control the locking and disconnection of the steering motor, road sense motor and electromagnetic lock according to the rotation angle signal, so as to realize the mechanical connection between normal steering and failure, and ensure that the vehicle does not lose its steering ability under any circumstances. The device of the invention has a compact structure and takes up little space. When the motor fails, it can be transformed into a motor power steering mode or a purely mechanical steering mode without affecting the steering system.

Owner:JIANGSU UNIV

Lens barrel and optical apparatus

A lens barrel having a reduced size and a related optical apparatus is disclosed. The lens barrel includes a cylindrical fixed frame and a cylindrical movable frame. The cylindrical first frame includes an outer wall extending around the optical axis and a cylindrical second frame is inserted thereto the first frame. The first frame includes a notch having first assembly portions at both side portions. The second frame includes second assembly portions that are assembled to be fixed to the first assembly portions.

Owner:SAMSUNG ELECTRONICS CO LTD

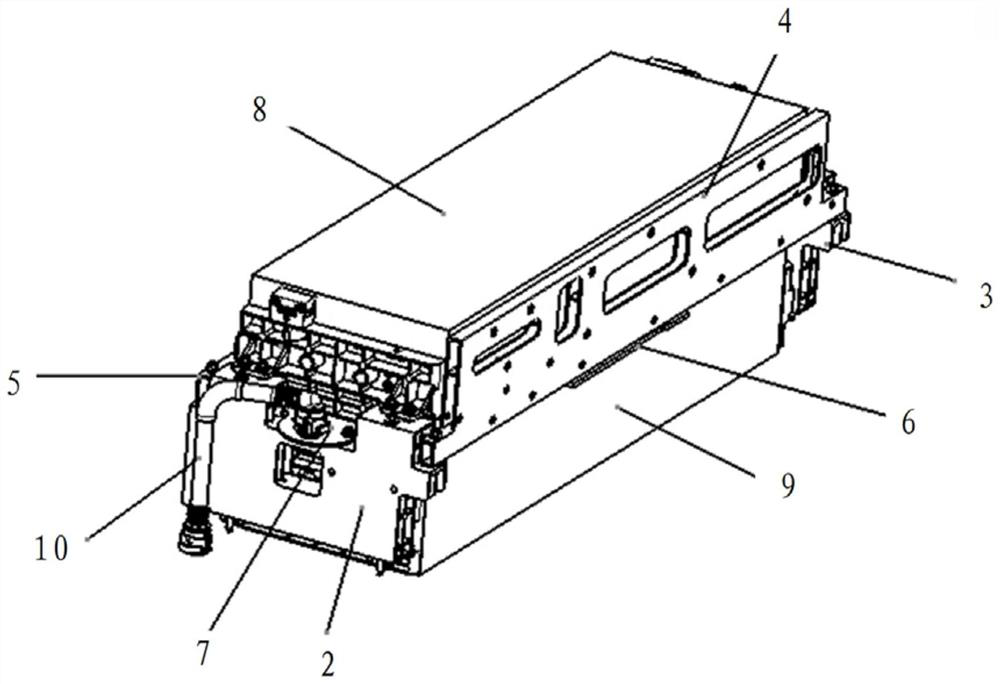

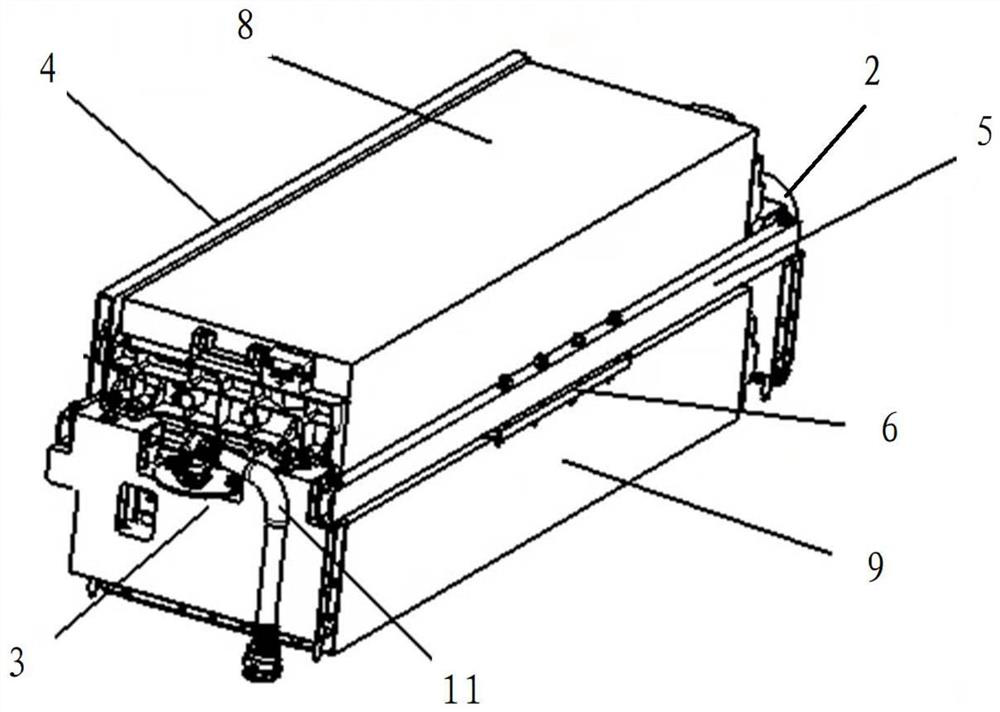

Battery module supporting device and vehicle

ActiveCN113782883AGuaranteed structural strengthAvoid deformationSecondary cellsCell component detailsEngineeringMechanical engineering

The invention discloses a battery module supporting device and a vehicle, and belongs to the technical field of vehicles. The battery module supporting device comprises a liquid cooling plate, a first bracket, a second bracket, a BMS bracket and a suspension cross beam; the first end of the BMS bracket is fixedly connected with the first bracket, the second end of the BMS bracket is fixedly connected with the second bracket, and the first bracket is opposite to the second bracket; the first end of the suspension cross beam is fixedly connected with the first bracket, and the second end of the suspension cross beam is fixedly connected with the second bracket; the first end of the liquid cooling plate is fixedly connected with the first bracket, and the second end of the liquid cooling plate is fixedly connected with the second bracket; and the two sides of the liquid cooling plate are fixedly connected with the BMS bracket and the suspension cross beam respectively. With the battery module supporting device of the invention adopted, the system integration level can be improved, the space required for arrangement is reduced, the structural stability is improved, and the flatness of battery cells in the middle of a battery module is ensured.

Owner:DONGFENG MOTOR GRP

Lightweight modularized liquid attitude and orbit control engine

PendingCN114030655AReduce overall layout spaceReduce weightCosmonautic vehiclesSpacecraft guiding apparatusCombustion chamberControl theory

The invention discloses a lightweight modularized liquid attitude and orbit control engine which comprises a shell, a combustion chamber, an injector, a high-temperature-resistant sealing gasket, a bearing, a propellant inlet connector, a sealing spherical surface, a sealing ring and a shaft type electromagnetic valve. According to the invention, the engine is subjected to lightweight modular design, and a shaft type electromagnetic valve and rotary sliding type injector structure is adopted, so that the working mode of function interchange among the engine injectors is realized on the basis of basically not increasing the weight of a power system and the layout space, and the redundancy and reliability of an engine module are improved. Under a certain condition, the number of the injectors in the engine module can be even reduced, and the layout space and the weight of each engine are reduced.

Owner:贵州航天朝阳科技有限责任公司

Variable braking force device of high-sensitivity brake

PendingCN113483041ASimple designIncrease braking powerBrake actuating mechanismsActuatorsPistonAutomotive engineering

The invention belongs to the technical field of driving braking of high-sensitivity brakes, and discloses a variable braking force device of a high-sensitivity brake. A brake cylinder body is a hollow cylinder with two closed ends, a first piston is fixedly arranged in a brake releasing cavity of the brake cylinder body, and a second piston is fixedly arranged at the position, close to the right side, of a brake rod. The left end of the brake rod is fixedly connected with the middle position of the right side of the first piston, and the right end of the brake rod penetrates through a brake cavity and extends out of the right side of the brake cylinder body. A brake shoe is fixedly arranged at the right end of the brake rod. The brake releasing cavity is fixedly formed in the left side of the brake cylinder body, and the brake cavity is fixedly arranged on the right side of the brake releasing cavity. Under the working condition that the size of the brake is not changed, the braking force can be improved, the machining precision of the brake is improved, and the manufacturing cost of the brake is reduced.

Owner:中实洛阳重型机械有限公司

Mechanical workpiece grooving equipment and grooving method thereof

ActiveCN113600925AReduce the number of settings and layout spaceQuality assuranceMeasurement/indication equipmentsFeeding apparatusPhysicsServo

The invention relates to mechanical workpiece grooving equipment and a grooving method thereof. The mechanical workpiece grooving equipment comprises a metal pin cutter (29), a first servo motor (23) and a clamping and fixing piece (34), and the first servo motor (23) enables the metal pin cutter (29) to move in the vertical direction through a first transmission structure and grooves a metal workpiece (7); and when the metal pin cutter (29) rotates at a high speed to act on the metal workpiece (7), the first servo motor (23) enables the clamping and fixing piece (34) to clamp the metal workpiece (7) through a second transmission structure. According to the mechanical workpiece grooving equipment, the first servo motor is matched with the different transmission structures, so that descending of the metal pin cutter, clamping of the metal workpiece and closing of a camera protection cavity can be achieved at the same time, it is ensured that the metal pin cutter, the metal workpiece and the camera protection cavity act synchronously, and the arrangement number and the arrangement space of driving devices are reduced.

Owner:深圳市宇星塑胶五金制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com