Motor protection type electric-controlled brake booster

A technology for electronically controlled braking and motor protection, applied in the direction of brakes, brake transmissions, vehicle components, etc., can solve the problems of increasing product development costs, unable to protect the motor from waterproofing, increasing the motor damage rate, etc., to reduce the space layout and the complexity of the system, the effect of reducing the modification of parts and extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

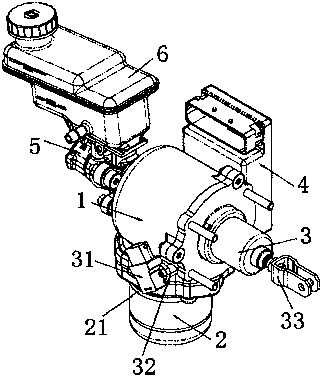

[0030] Such as figure 1 Shown is a schematic diagram of the overall structure of the present invention, an electronically controlled brake booster, including a motor 2, a transmission mechanism, a pedal input mechanism 3, a housing assembly 1, an electronic control unit 4, a brake master cylinder 5 and a liquid storage tank 6. The pedal input mechanism 3 is fixedly installed at the rear end of the housing assembly 1, the motor 2 is fixedly installed at the lower end of the housing assembly 1, the brake master cylinder 5 is fixedly installed at the front end of the housing assembly 1, and the brake master The other end of the cylinder 5 is also fixedly installed with a liquid storage tank 6 , and the transmission mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com