Power transmission case

A technology of power transmission box and box body, which is applied in the direction of transmission box, transmission device, transmission device parts, etc., can solve the problems that do not fully meet the needs of fast multi-functional work vehicles, mature products of power transmission box that do not meet working conditions, etc., and achieve structural Simple and practical, simple structure, large moment bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

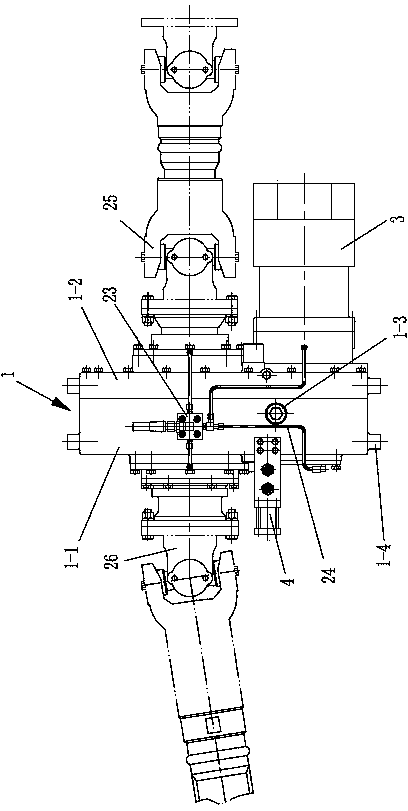

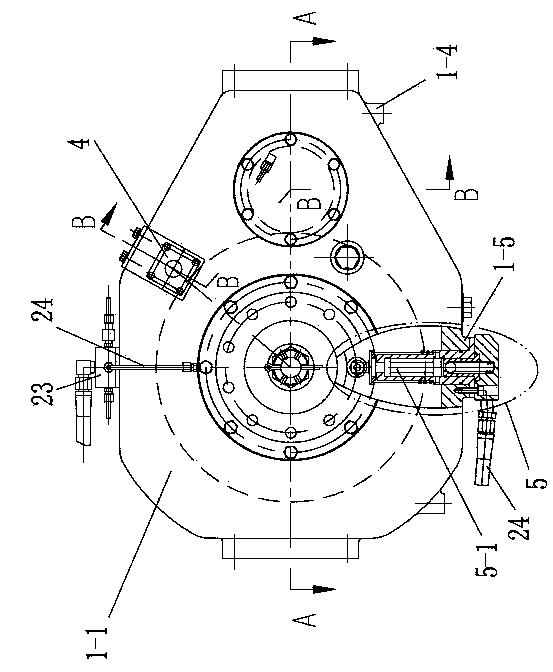

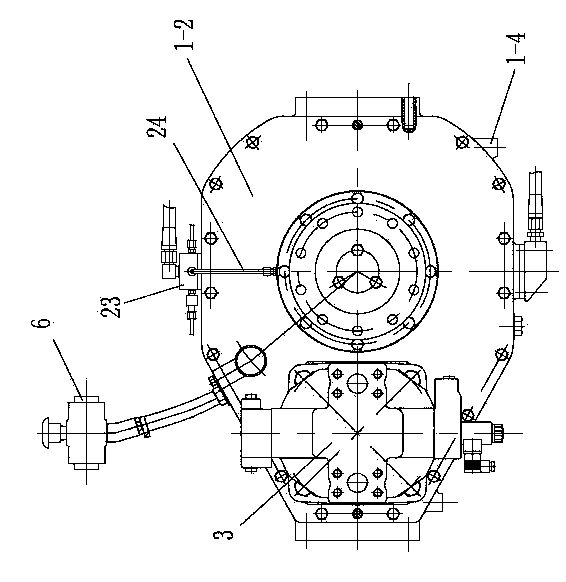

[0031] Such as figure 1 , 2 , 3, 4, and 5, a power transmission box of the present invention includes a box body 1, an input shaft 16, an output shaft 18, a driving gear 13, a driven gear 7, a shift clutch, a toggle mechanism 4, and a hydraulic The motor 3, the toggle mechanism 4 is mounted on the box 1, the hydraulic motor 3 is connected to the input shaft 16, the box 1 includes a left box 1-1 and a right box 1-2, the left box 1 -1 and the right casing 1-2 split planes are vertical planes, the driving gear 13 is constantly meshed with the driven gear 7, and the wheel hole of the driving gear 13 is provided with a bearing seat 13-1 and an internal spline 13-2 , Two ball bearings 12 are installed in the bearing seat 13-1, the driving gear 13 is rotatably supported on the input shaft 16 through the two ball bearings 12, the input shaft 16 has an external spline 16-1, the shift clutch It is composed of a gear shift sleeve 14, a gear sleeve positioning mechanism 17 and a driving ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com