Battery module supporting device and vehicle

A technology for a support device and a battery module, which is applied in the field of vehicles, can solve the problems of bending and deformation of the liquid-cooling plate, affecting the service life of the liquid-cooling plate, etc., to ensure the flatness, reduce the space required for layout, and improve the structural stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

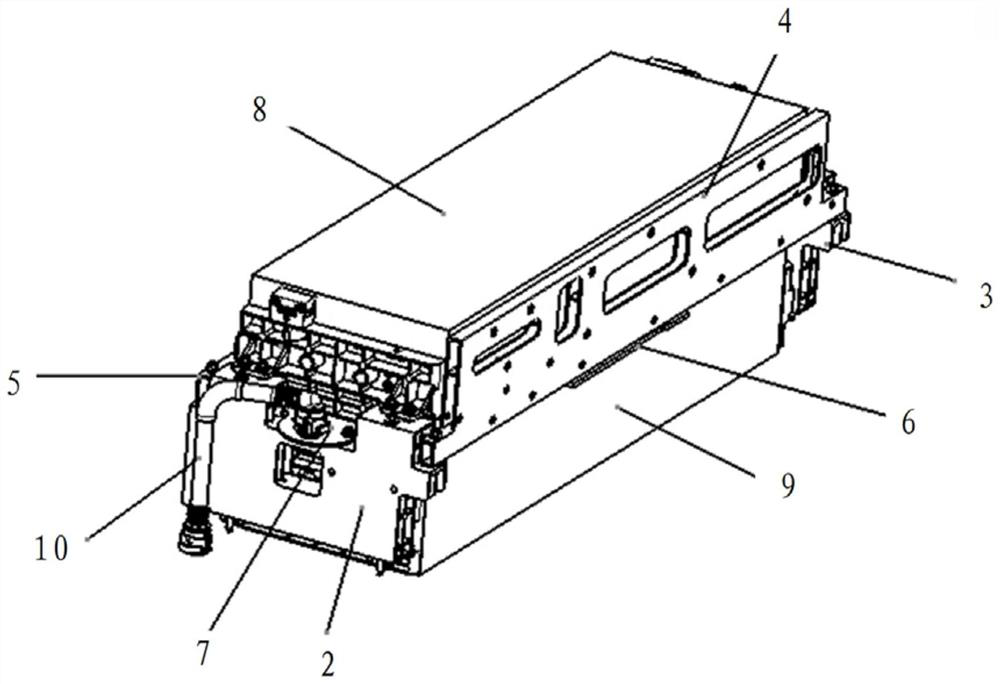

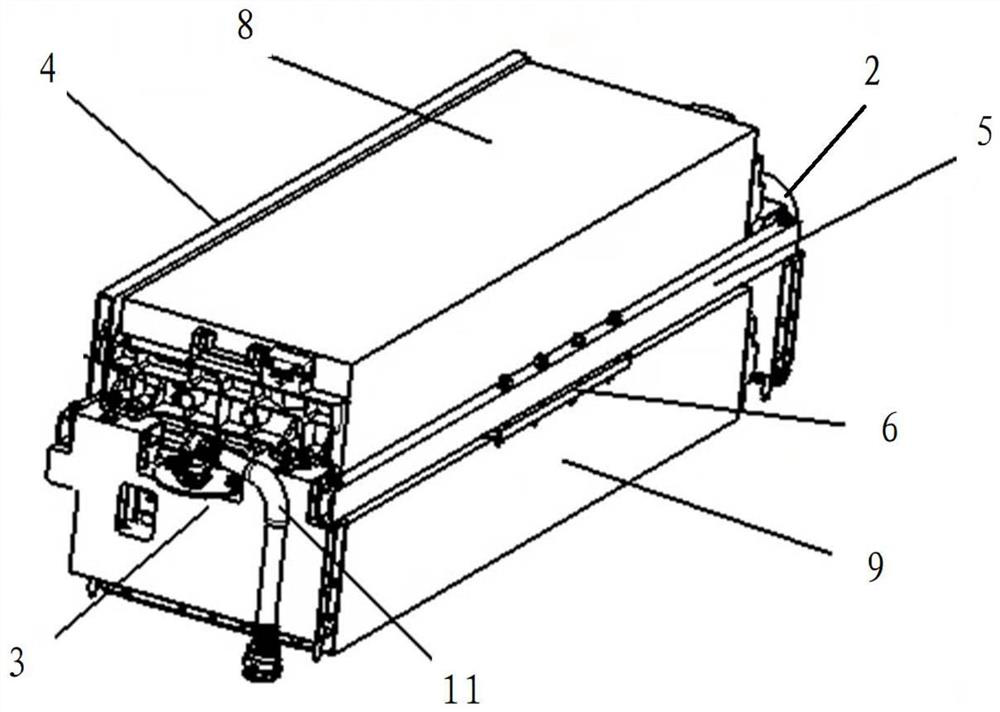

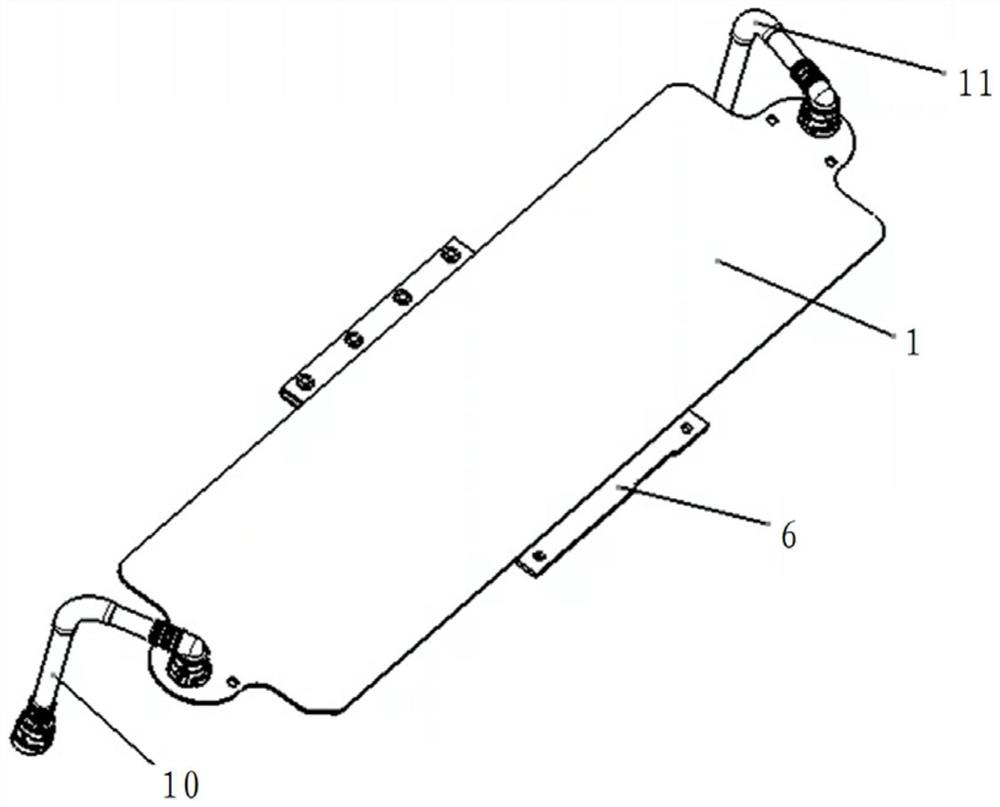

[0022] see Figure 1-3 , A battery module supporting device provided by an embodiment of the present invention includes: a liquid cooling plate 1 , a first bracket 2 , a second bracket 3 , a BMS bracket 4 and a suspension beam 5 .

[0023] The first end of the BMS support 4 is fixedly connected to the first support 2 , the second end of the BMS support 4 is fixedly connected to the second support 3 , and the first support 2 is opposite to the second support 3 .

[0024] The first end of the suspension beam 5 is fixedly connected to the first bracket 2 , and the second end of the suspension beam 5 is fixedly connected to the second bracket 3 .

[0025] The first end of the liquid cooling plate 1 is fixedly connected to the first bracket 2 , and the second end of the liquid cooling plate 1 is fixedly connected to the second bracket 3 .

[0026] Both sides of the liquid cooling plate 1 are fixedly connected to the BMS support 4 and the suspension beam 5 respectively.

[0027] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com