Novel reducing square bend and flue gas pipeline system

A new type of elbow technology, applied in the field of new variable diameter square elbow and flue gas pipeline system, can solve the problems of small bending angle of equal diameter elbow, sudden change of elbow section, pipeline vibration and noise, etc., and achieve reduction Effects of flow field resistance, reducing resistance and layout space, reducing vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

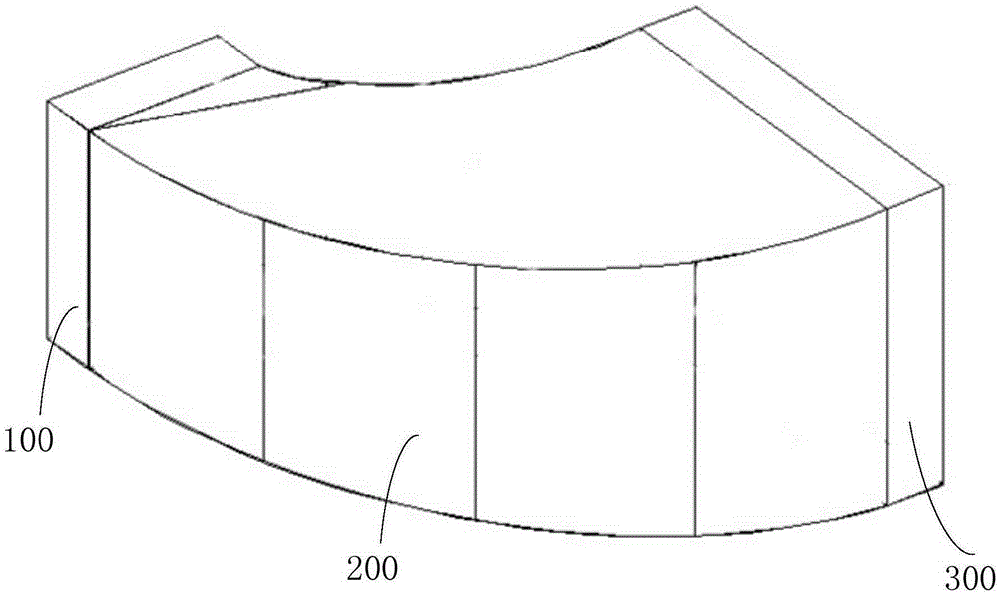

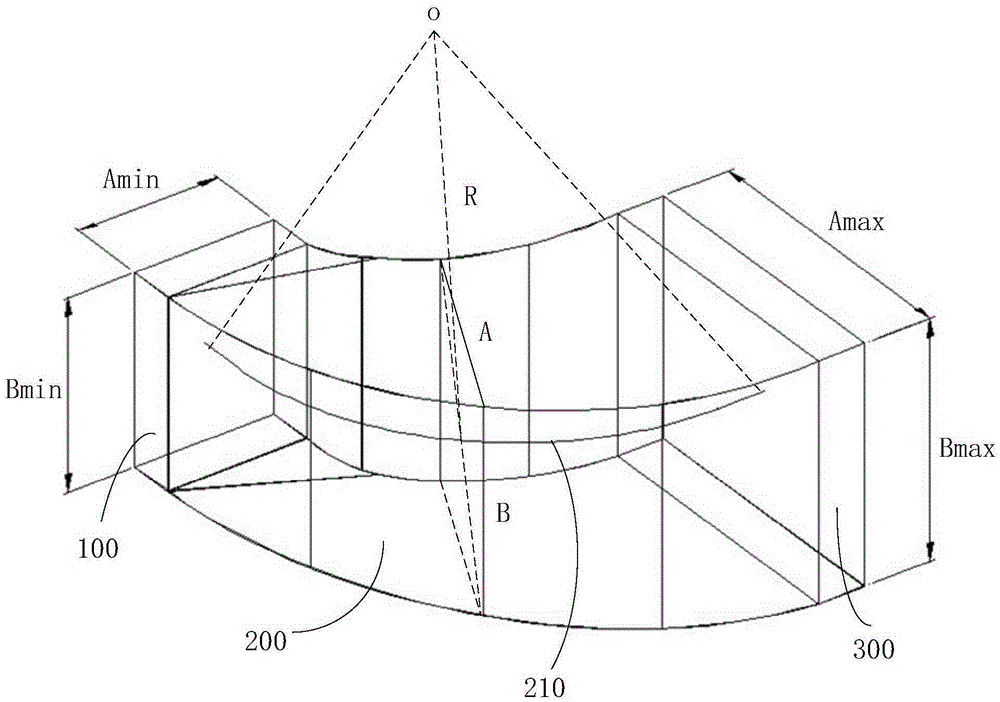

[0022] like Figure 1 to Figure 2 As shown, a new type of reducing square elbow, including a large end 300 and a small end 100, and a smooth transition connecting the large end 300 and small end 100 of the variable diameter section 200, the large end 300, small end 100 and The cross-sections of the reducing section 200 are set to quadrilaterals; and, on the reducing section 200, R=1~5D; wherein, R is the radius of curvature at any point on the center line 210 of the reducing section, D is the length of the longer diagonal of the cross-sectional quadrilateral at that point. Moreover, since the cross-section of the diameter-reducing section 200 changes, the radius of curvature R also changes with the change of the cross-section.

[0023] By controlling the radius of curvature R=1~5D at any point on the center line 210 of the quadrilateral diameter redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com