Loading simulation device for test bed of wind turbine

A technology of wind power generators and loading devices, which is applied in the direction of engine testing, measuring devices, and testing of machine/structural components. The effect of layout space and cost, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

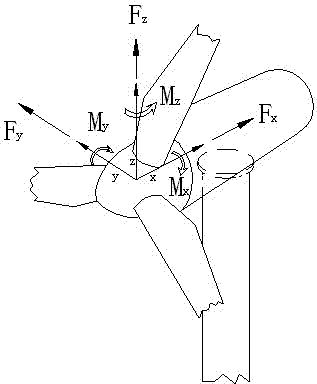

[0016] Such as figure 1 As shown, when the wind turbine is actually running, it is subjected to axial force , radial force and , the torque around the x-axis , the bending moment around the y-axis and the z-axis and The load of six degrees of freedom, therefore, to ensure the accuracy of the test results of the wind turbine test bench, it is necessary to simulate the load under the actual operating conditions of the wind turbine.

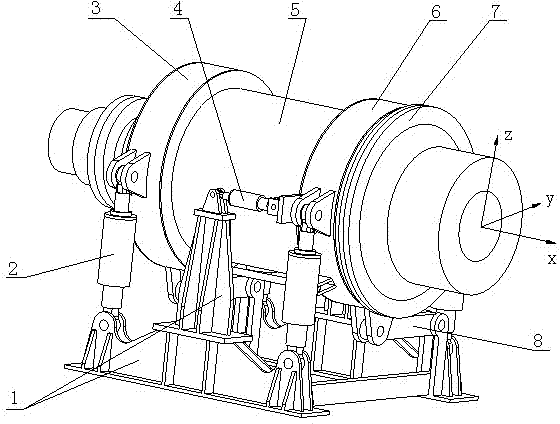

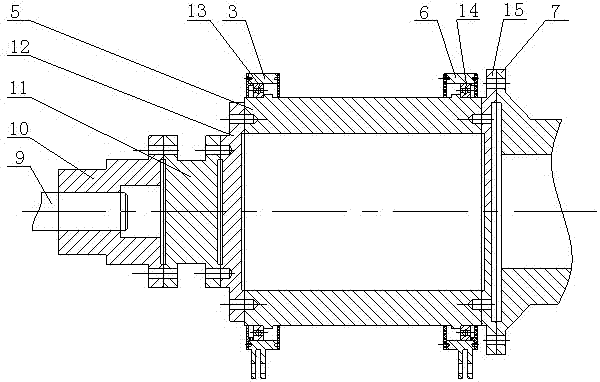

[0017] The structure of the present invention is as figure 2 , image 3 As shown, the present invention includes a torque sensor 11, a loading shaft 5, two loading bearing seats 3,6, four vertical double-acting oil cylinders 2, two axial double-acting oil cylinders, and two connecting rods 8; the drive shaft 9 passes through Single flange flexible coupling 10, torque sensor 11, flange 12 are connected to loadin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com