Flexible super capacitor and preparing method thereof

A supercapacitor and flexible technology, applied in the manufacture of hybrid/electric double-layer capacitors, electrodes of hybrid capacitors, etc., can solve the problems of weak bonding between semiconductor materials and flexible fibrous substrates, low specific energy of capacitors, and long electron transmission paths. To achieve the effect of easy promotion, reducing magnification difference, and reducing the appearance of easy damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of above-mentioned flexible supercapacitor comprises the steps:

[0022] (1) Select two linear flexible fibrous substrates, and bend one end of one of them into a helical shape.

[0023] (2) Covering the helical flexible fibrous substrate and the linear flexible fibrous substrate obtained in step (1) with a semiconductor material having pseudocapacitive properties as the first electrode and the second electrode, respectively.

[0024] When the semiconductor material with pseudocapacitive properties is nickel cobaltate with nanostructure, the step further includes the following steps:

[0025] (2-1) Prepare a mixed solution of nickel chloride, cobalt chloride, ammonium fluoride and urea, wherein the concentration of nickel chloride is 0.03~0.12mol / L, and the concentration of cobalt chloride is 0.06~0.24mol / L , the concentration of ammonium fluoride is 0-0.45 mol / L, and the concentration of urea is 0.12-0.18 mol / L.

[0026] (2-2) Pour the above so...

Embodiment 1

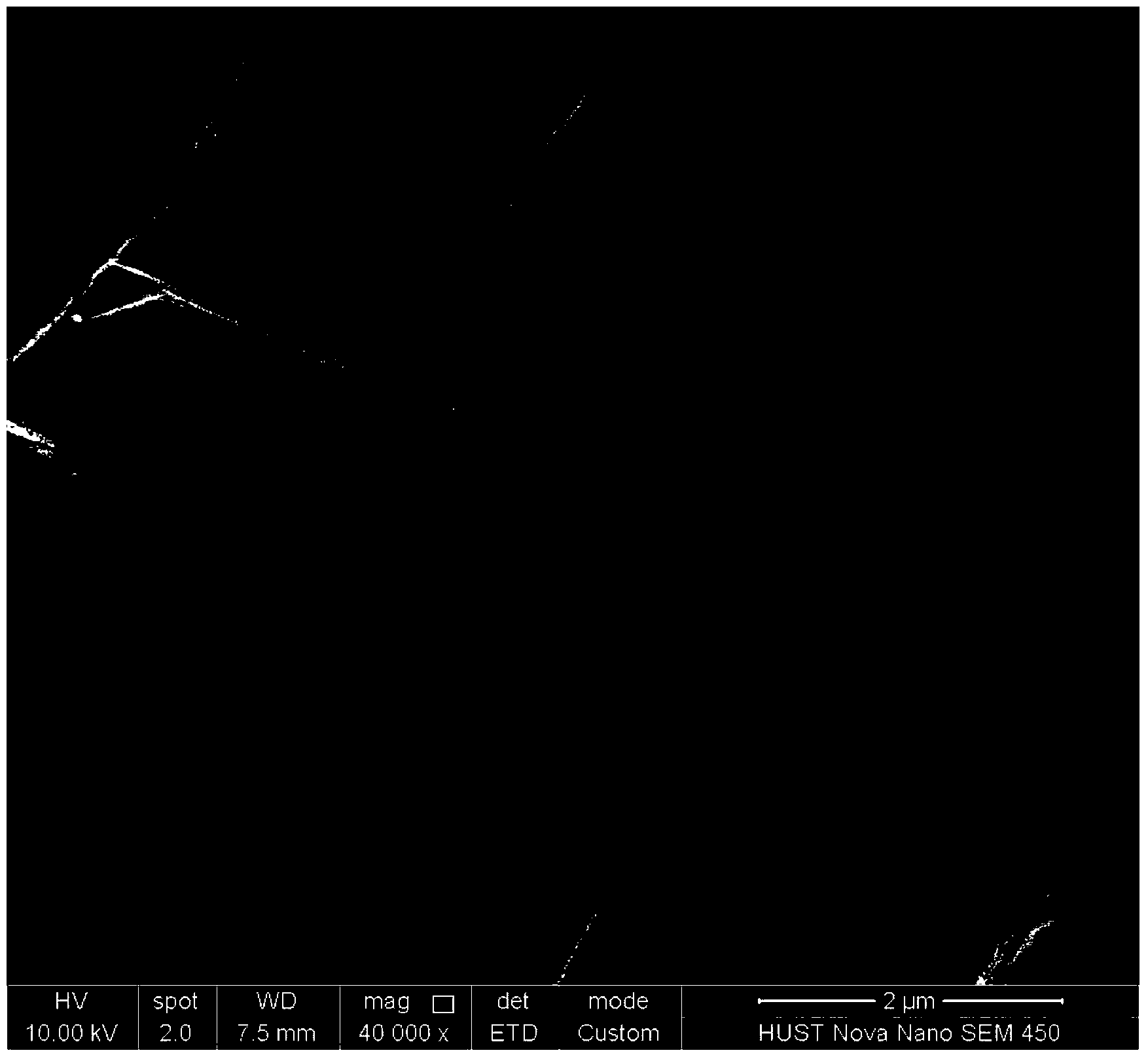

[0035] Clean a nickel wire with a diameter of 200 microns in acetone, water and ethanol in sequence, and after drying, bend one end of a nickel wire into a spiral shape with an inner diameter of about 1 mm and put it into a high-pressure tube together with another wire-shaped nickel wire. In the lining of the autoclave; pour 30mL of the mixed solution of nickel chloride, cobalt chloride and urea into the lining of the autoclave, wherein the concentration of nickel chloride is 0.03mol / L, and the concentration of cobalt chloride is 0.06mol / L L, the concentration of urea is 0.12mol / L; put the reactor into a drying oven at 120°C to react for 6 hours, and cool to room temperature naturally after the reaction; take out the sample and calcinate it in a muffle furnace at 300°C for 3 hours, A first electrode and a second electrode of nickel cobaltate covered with nanostructures are obtained. From the scanning electron microscope photos, it can be seen that the needle-like nanowires are...

Embodiment 2

[0038]Clean a nickel wire with a diameter of 200 microns in acetone, water and ethanol in sequence, and after drying, bend one end of a nickel wire into a spiral shape with an inner diameter of about 1 mm and put it into a high-pressure tube together with another wire-shaped nickel wire. In the lining of the autoclave; pour 30mL of the mixed solution of nickel chloride, cobalt chloride and urea into the lining of the autoclave, wherein the concentration of nickel chloride is 0.12mol / L, and the concentration of cobalt chloride is 0.24mol / L L, the concentration of urea is 0.12mol / L; put the reaction kettle into a 150°C oven for 12 hours, and cool to room temperature naturally after the reaction; take out the sample and calcinate it in a muffle furnace at 300°C for 3 hours, A first electrode and a second electrode of nickel cobalt oxide covered with nanostructures are obtained. From the scanning electron microscope photos, it can be seen that the nanowires are obviously thicker a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com