A hollow shaft synchronous double countershaft transmission structure and its shifting method

A technology of double intermediate shafts and intermediate shafts, which is applied to vehicle gearboxes, components with teeth, gear transmissions, etc., can solve the problems of high manufacturing cost, small layout space, and large layout space, so as to reduce production costs, The effect of small layout space and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

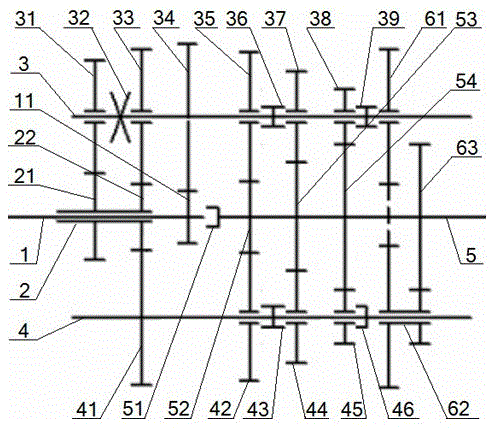

[0072] see figure 1 , a hollow-shaft synchronous double countershaft transmission structure, including a solid input shaft 1 and a hollow input shaft 2, the solid input shaft 1 is driven and matched with the output shaft 5 through an odd-numbered gear counter shaft 3, and the hollow input shaft 2 is passed through Even-number gear intermediate shaft 4 is in transmission cooperation with output shaft 5; the hollow input shaft 2 is sequentially sleeved with hollow shaft fixed synchronous gear 21 and hollow shaft fixed gear 22 from its head end, and the hollow shaft fixed gear 22 respectively meshes with the idler gear 33 of the odd-numbered gear intermediate shaft and the fixed gear 41 of the even-numbered gear intermediate shaft. The shaft 3 is sequentially set with an odd-numbered intermediate shaft idler synchronous gear 31, a synchronous friction wheel 32, an odd-numbered intermediate shaft idler gear 33, an odd-numbered intermediate shaft fixed gear 34, and an odd-numbered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com