Spiral distribution convergent micropore texture mechanical seal

A mechanical seal and microporous technology, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems affecting the reliability and service life of seals, limited hydrodynamic and static pressure effects, and end face rubbing, etc., to improve the start-stop. effect, large axial stiffness, stable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

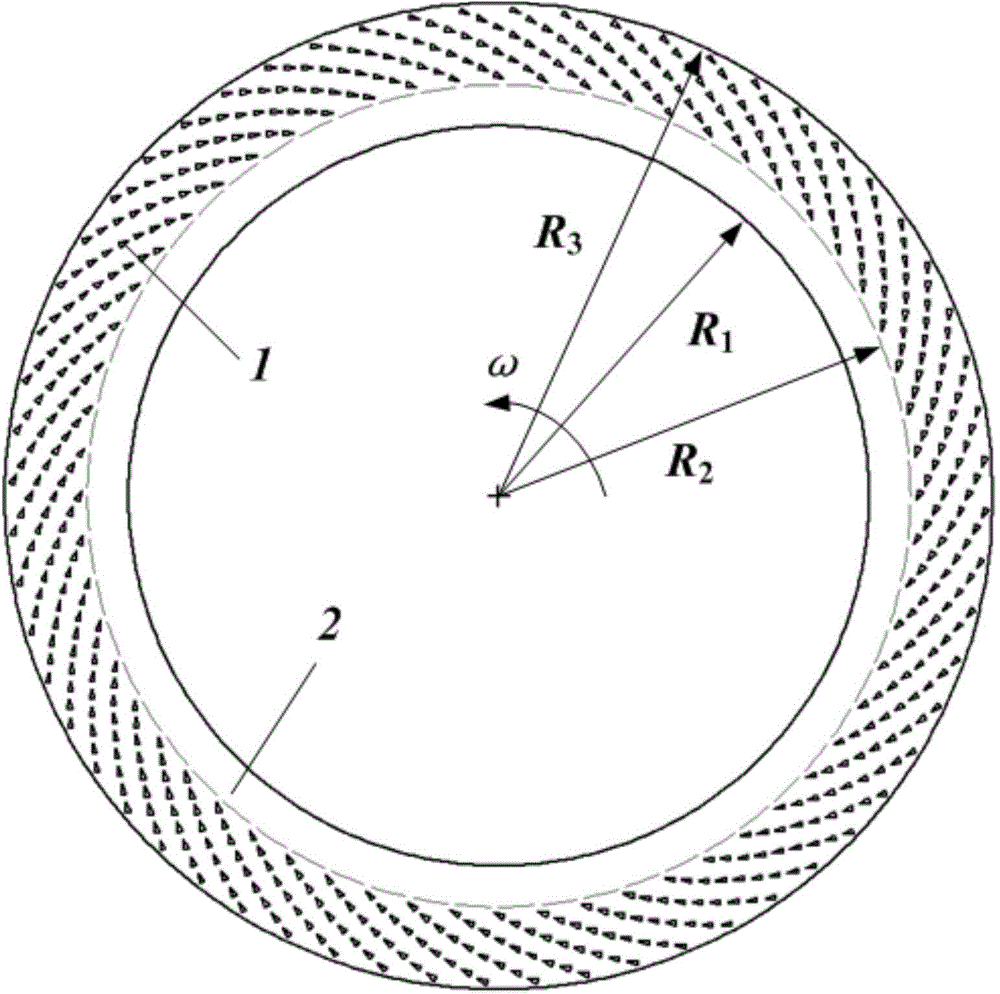

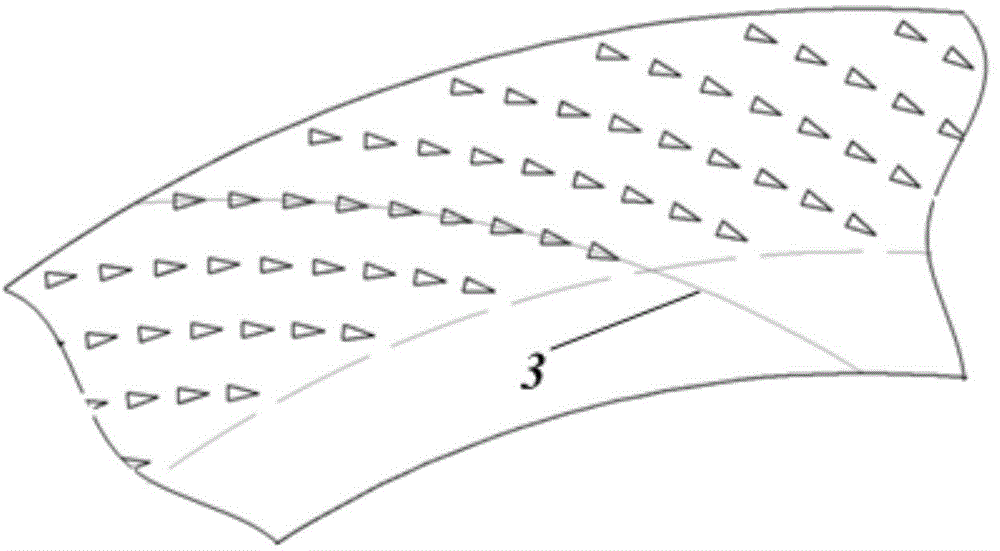

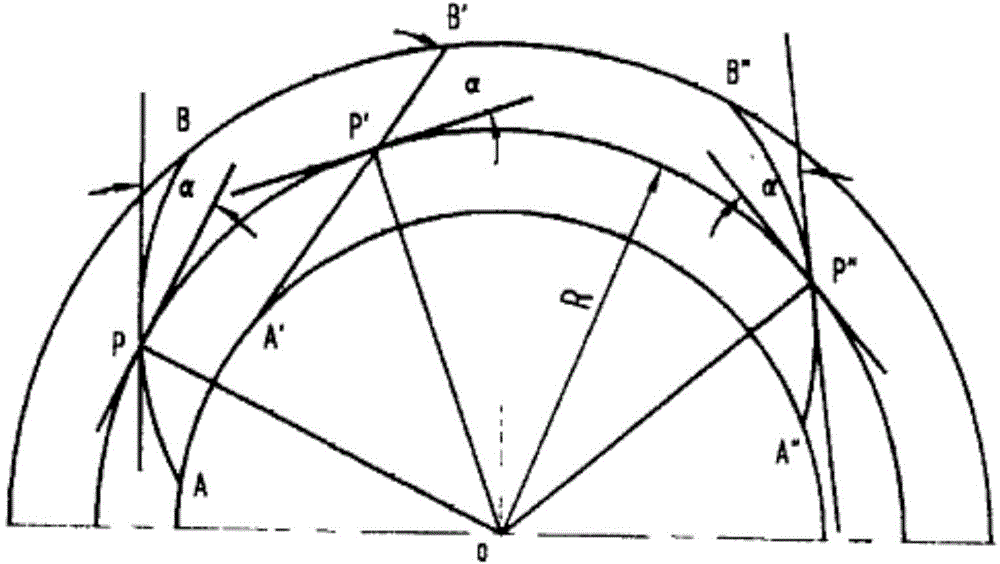

[0030] figure 1 It is a schematic diagram of Embodiment 1 of the present invention. figure 1 In the seal shown, the outer side of the sealing ring end face is the high pressure side, that is, the upstream side, and the inner side of the sealing end face is the low pressure side, that is, the downstream side. On the static ring 5 and the moving ring 4 (or one of them), the spirally distributed convergent microporous texture is processed, the texture band 1 is located on the end surface close to the outer diameter side, and the dam area 2 is located on the end surface close to the inner diameter side.

Embodiment 2

[0032] Figure 6 It is a schematic diagram of Embodiment 2 of the present invention. Figure 6 In the seal shown, the outer side of the sealing ring end face is the high pressure side, that is, the upstream side, and the inner side of the sealing end face is the low pressure side, that is, the downstream side. On the static ring 5 and the moving ring 4 (or one of the two), the spirally distributed convergent microporous texture is processed, and the texture band 1 covers the entire ring surface without a dam area.

Embodiment 3

[0034] Figure 7 It is a schematic diagram of Embodiment 3 of the present invention. Figure 7In the seal shown, the inner side of the sealing ring end face is the high pressure side, that is, the upstream side, and the outer side of the sealing end face is the low pressure side, that is, the downstream side. On the static ring 5 and the moving ring 4 (or one of them), the spirally distributed convergent microporous texture is processed, the texture band 1 is located on the end surface close to the inner diameter side, and the dam area 2 is located on the end surface close to the outer diameter side.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com