Lamp string and manufacturing method thereof

A light string, a pair of technology, applied in the field of semiconductor lighting, can solve the problems of low efficiency, difficult welding, etc., to achieve high efficiency, low welding difficulty, and facilitate the effect of quantitative production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

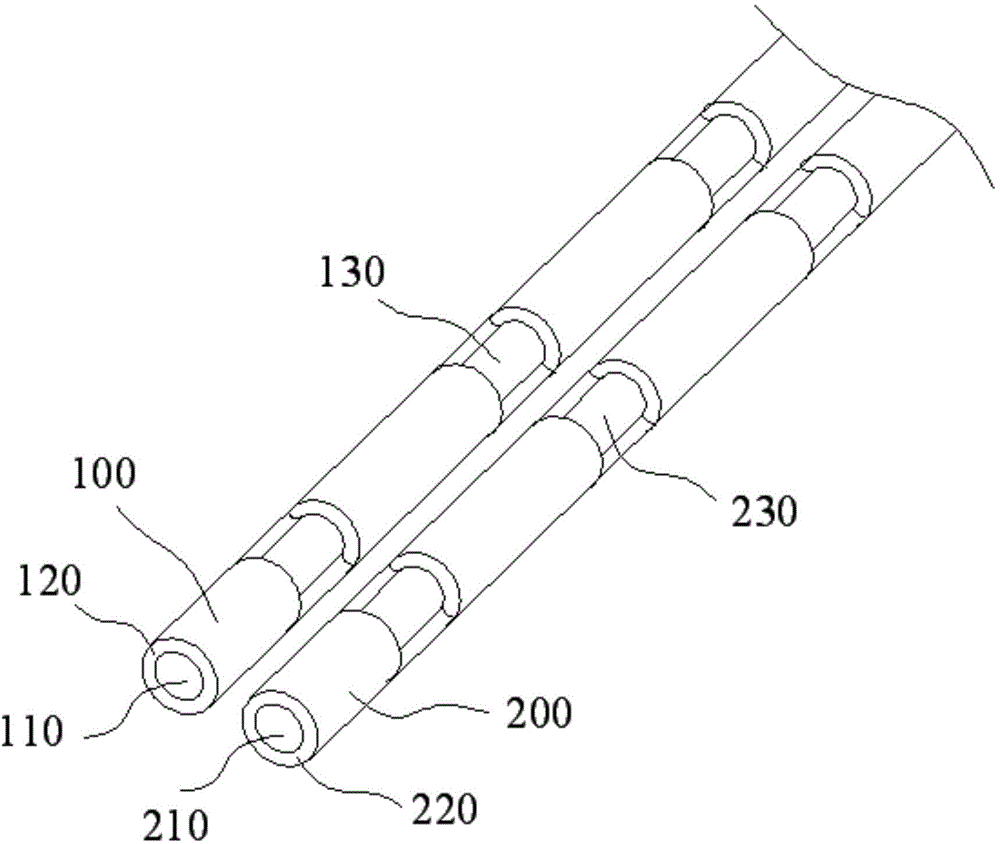

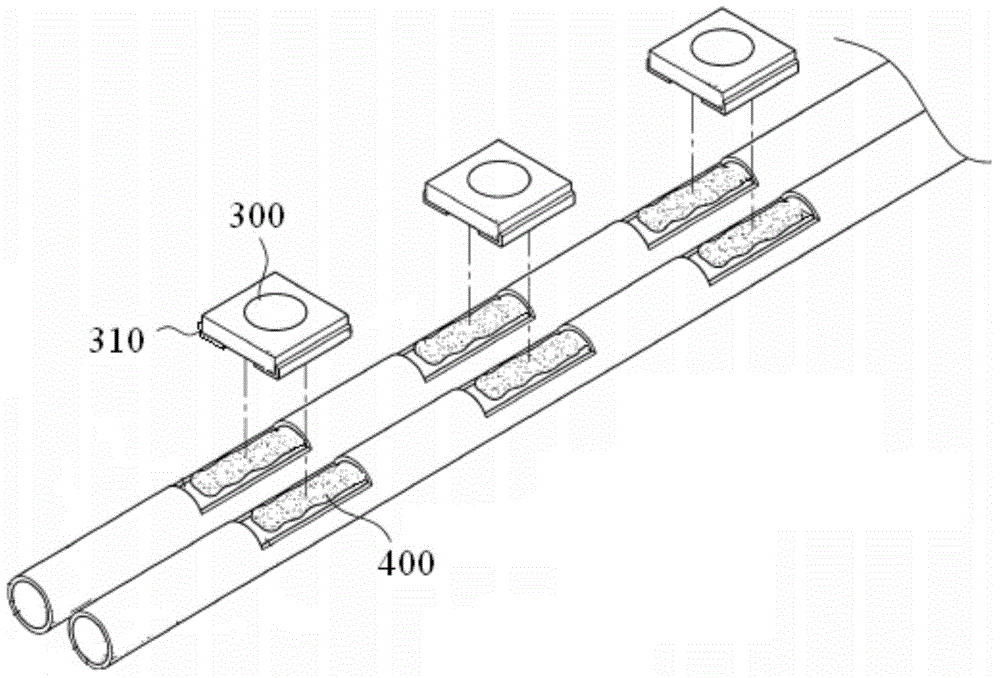

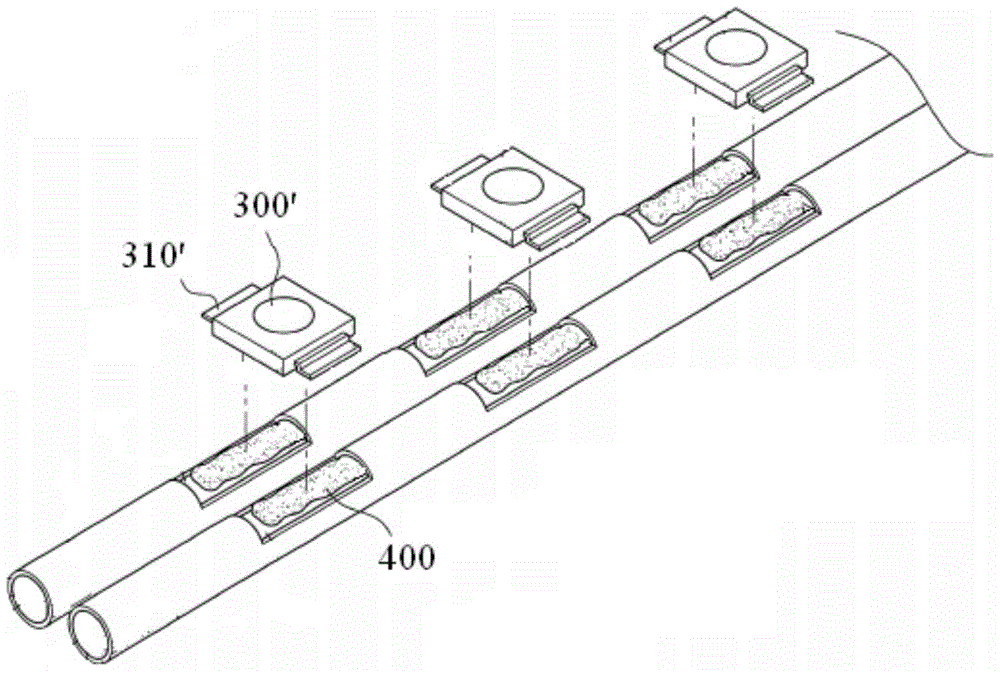

[0020] The light string provided by the present invention includes a plurality of light-emitting components and two wires arranged in parallel. Each wire is composed of a conductor and an insulating layer wrapped outside the conductor. opening, and a conductor contact surface is formed between the conductor at the opening and the insulating layer, the conductor contact surfaces at the corresponding positions of the two wires form a pair of conductor contact surfaces, and each of the light-emitting components is connected across the two wires A pair of conductor contact surfaces. Wherein, the light-emitting components can be LED light-emitting components, and the wires can be PVC wires, PE wires or electric wires. The two wires can be independent wires, or the two conductors can be covered under the same insulating layer, and the two conductors can be separated by an insulating material layer. The conductor can be a copper conductor, or it can be made of multiple copper wires ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com