Centralized control method for precision machine room air-conditioner system

A precision air conditioner and centralized control technology, which is applied in heating and ventilation control systems, heating and ventilation safety systems, heating methods, etc., can solve the problem of lack of a unified control system for multiple precision air conditioners, frequent start and stop of a single air conditioner, and increased machine room maintenance Cost and other issues, to achieve strong economic value, reduce the number of starts and stops, and reduce maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

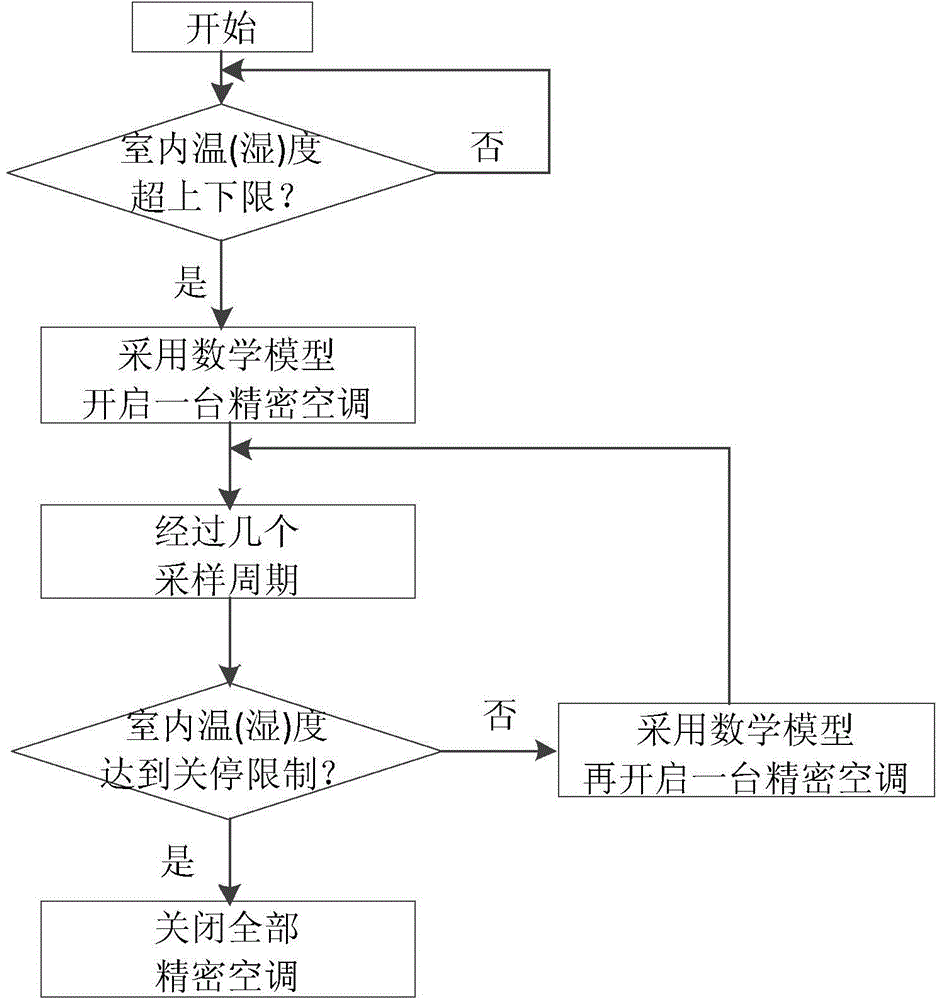

[0024] The centralized control method for the precision air-conditioning system in a machine room provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

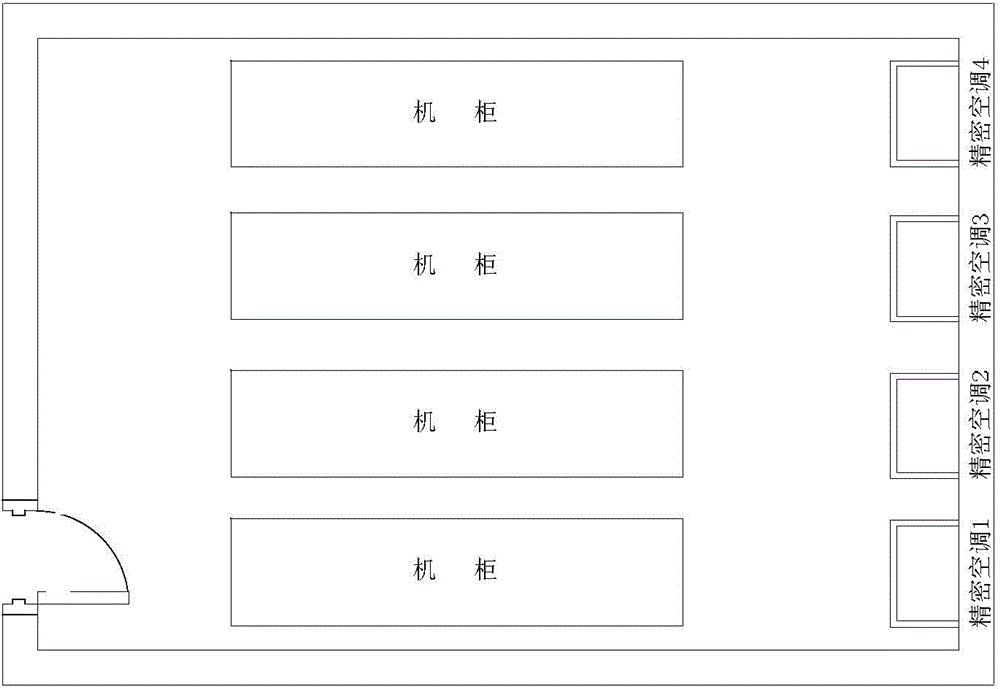

[0025] The present invention assumes that the indoor temperature is evenly distributed, that the air conditioners are placed on the same side of the machine room with uniform intervals, and that a single air conditioner has the ability to reduce the indoor temperature and humidity to a reasonable range. The placement of equipment and air conditioners in the computer room is as follows: figure 1 shown.

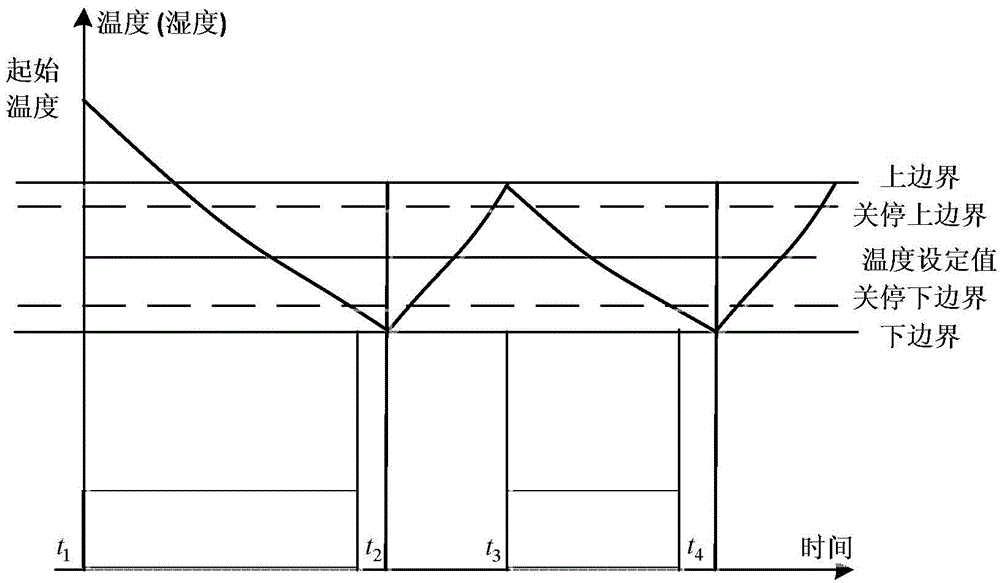

[0026] The basic dynamic process of precision air conditioning is as follows: figure 2 As shown, the indoor temperature (humidity) fluctuates around a certain temperature (humidity) setting value. Once the temperature (humidity) exceeds the upper and lower boundaries, the precision air conditioner will start; after the air conditioner is st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com