Container built-in remote visual explosion-proof liquid level gauge

A built-in liquid level instrument technology, applied in the field of liquid level instrument, can solve problems such as inaccurate measurement results, medium interference, unreliability, etc., and achieve the effect of high measurement accuracy, stable image, and data realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

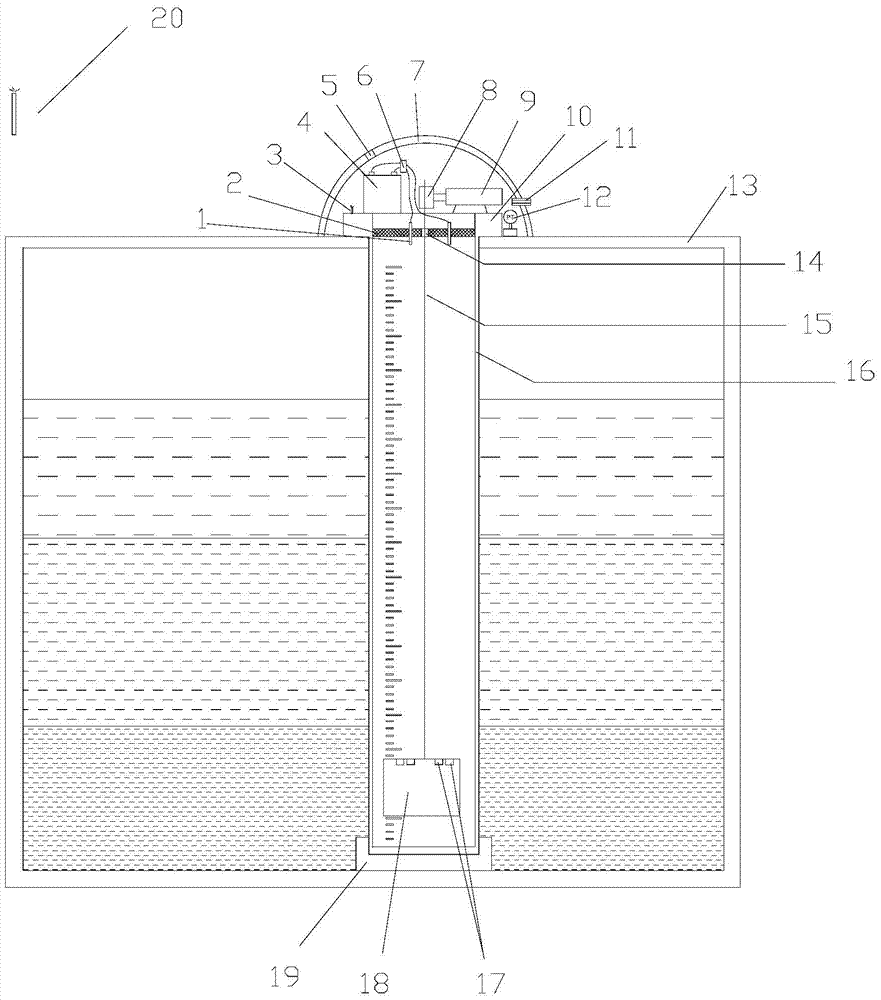

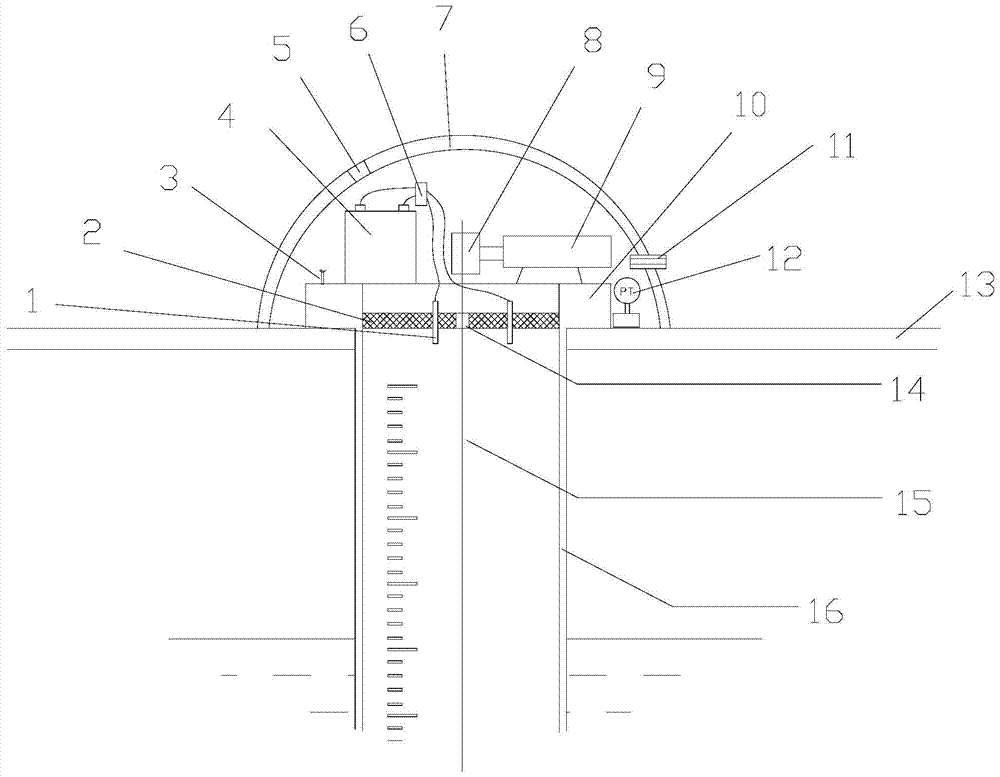

[0032] see figure 1 and figure 2 , the present invention provides a container built-in remote visual explosion-proof liquid level gauge, the following detailed description of the present invention through specific implementation:

[0033] The invention includes a sealing unit, a charging unit, a driving unit, an executing unit and a communication unit. The charging unit, driving unit and execution unit are all located in the sealed cavity formed by the sealing unit.

[0034] The sealing unit is a sealed chamber composed of a sealed cover 7 and a glass casing 16. The sealed chamber is filled with arc-extinguishing explosion-proof gas to ensure that the entire liquid level gauge is sealed and explosion-proof, so it can still penetrate into the container when observing flammable and explosive media. Internally observe the medium to collect stable and reliable information. The sealing cover 7 is installed above the glass protective tube 16 and is sealed with the top surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com