Finite element method and strength evaluation method for bolt

A finite element and bolt technology, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve the problems of heavy workload, affecting the development process, and low accuracy, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] 1) Establish a finite element model of the bolt, which includes the material properties and geometric dimensions of the bolt.

[0032] The bolt material is 30CrMnSiA, the elastic modulus is 200GP, the Poisson's ratio is 0.3, the yield stress is 735MPa, the ultimate strength is 1030MPa, and the elongation after fracture is 10%;

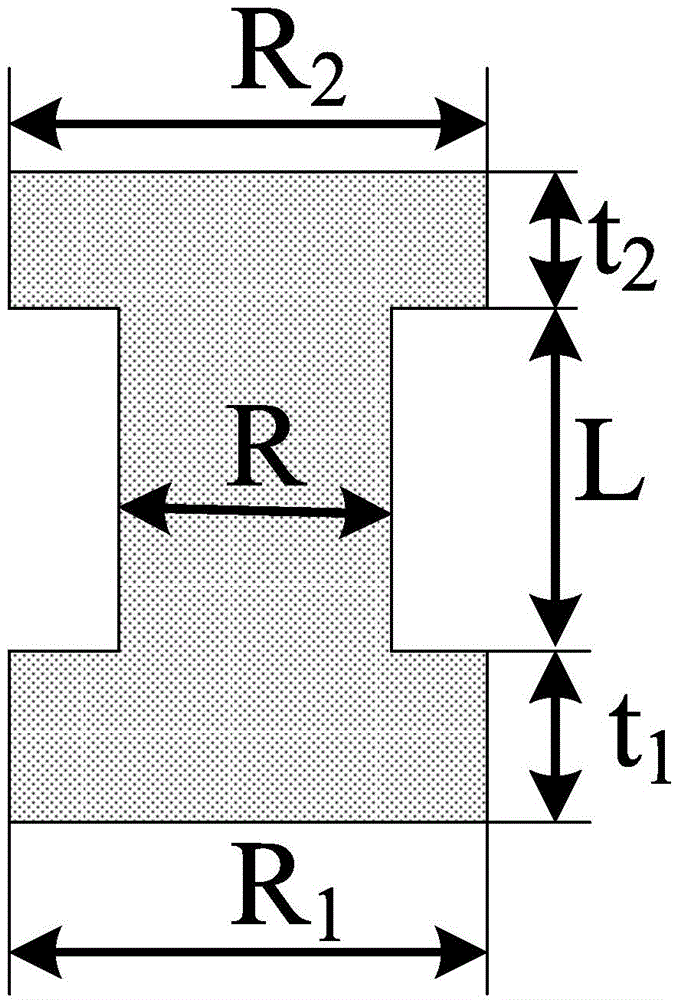

[0033] The geometric parameters of the bolts are as attached figure 1 As shown, the parameter values are: screw diameter R is 8mm, length L is 12mm, screw head diameter R 1 12mm, thickness t 1 3mm, nut diameter R 2 12mm, thickness t 2 Is 3mm;

[0034] 2) Establish a finite element model for the flange, which includes the material properties and geometric dimensions of the flange.

[0035] Flange material is 30CrMnSiA, elastic modulus is 200GP, Poisson's ratio is 0.3, yield stress is 735MPa, ultimate strength is 1030MPa, elongation after fracture is 10%;

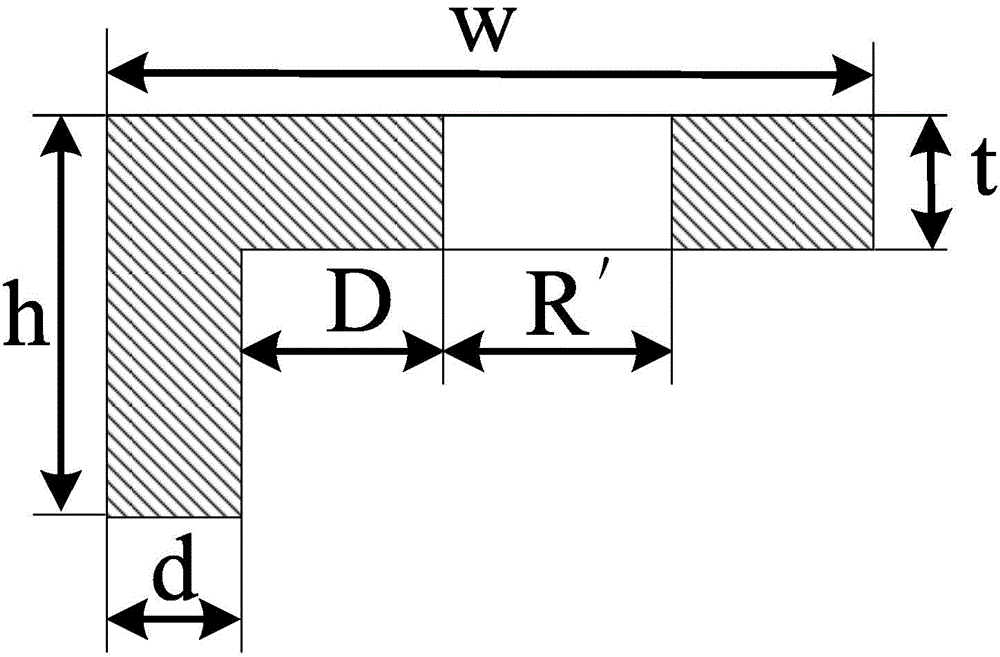

[0036] The geometric parameters of the flange are as attached figure 2 As shown, the parameter val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com