Cooling devices for rotors of electromechanical machines

A cooling device and mechanical technology, applied in cooling/ventilation devices, electromechanical devices, electric components, etc., can solve problems such as cost and achieve the effect of simple support and guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following detailed examples are preferred embodiments of the present invention.

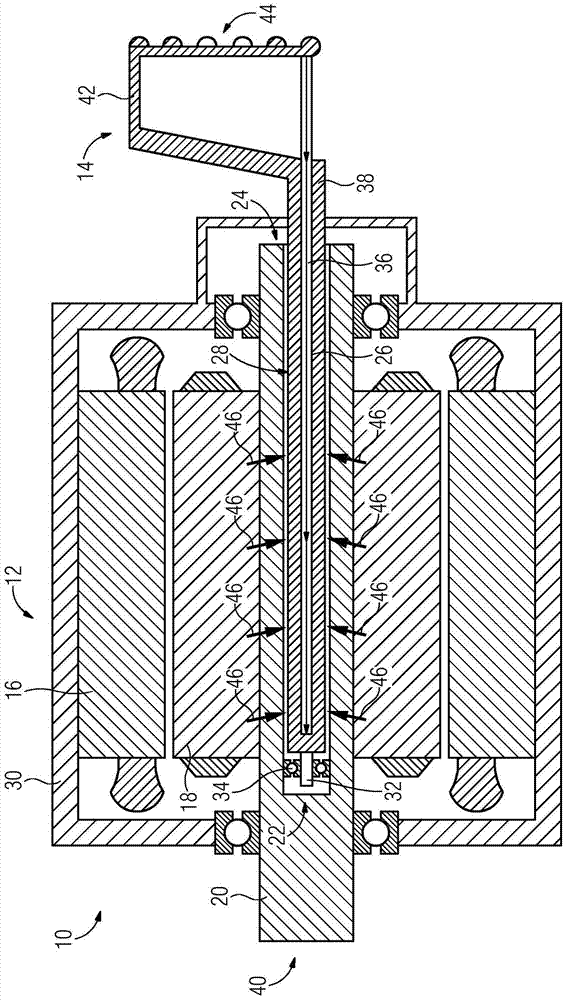

[0020] The drawing shows a sectional side view of the mechanical device 10 . The mechanical device 10 includes an electric machine 12 and a cooling member 14 described in more detail below.

[0021] The mechanical device 10 can be arranged, for example, in an electric vehicle for driving one or more drive wheels. In this case, the cooling component 14 can be associated with a cooling circuit of the electric vehicle. The cooling component 14 can also be associated with a cooling circuit of the electric machine 12 .

[0022] Electric machine 12 includes a stator 16 and a rotor 18 . The rotor 18 is mechanically connected to a shaft 20 . In this case, the shaft 20 includes a cutout 22 . The cutout 22 is preferably introduced as a bore into the shaft 20 from a first end side 24 thereof. In this case, the cutout 22 is designed as a blind hole which is inserted centrally into the shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com