Sloping shoulder type male die

A punch and oblique shoulder technology, applied in the field of stamping dies, can solve the problems of large punch head size, increase the installation space of the punch, and increase the cost of the mold, and achieve the effects of preventing damage, compact installation structure, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

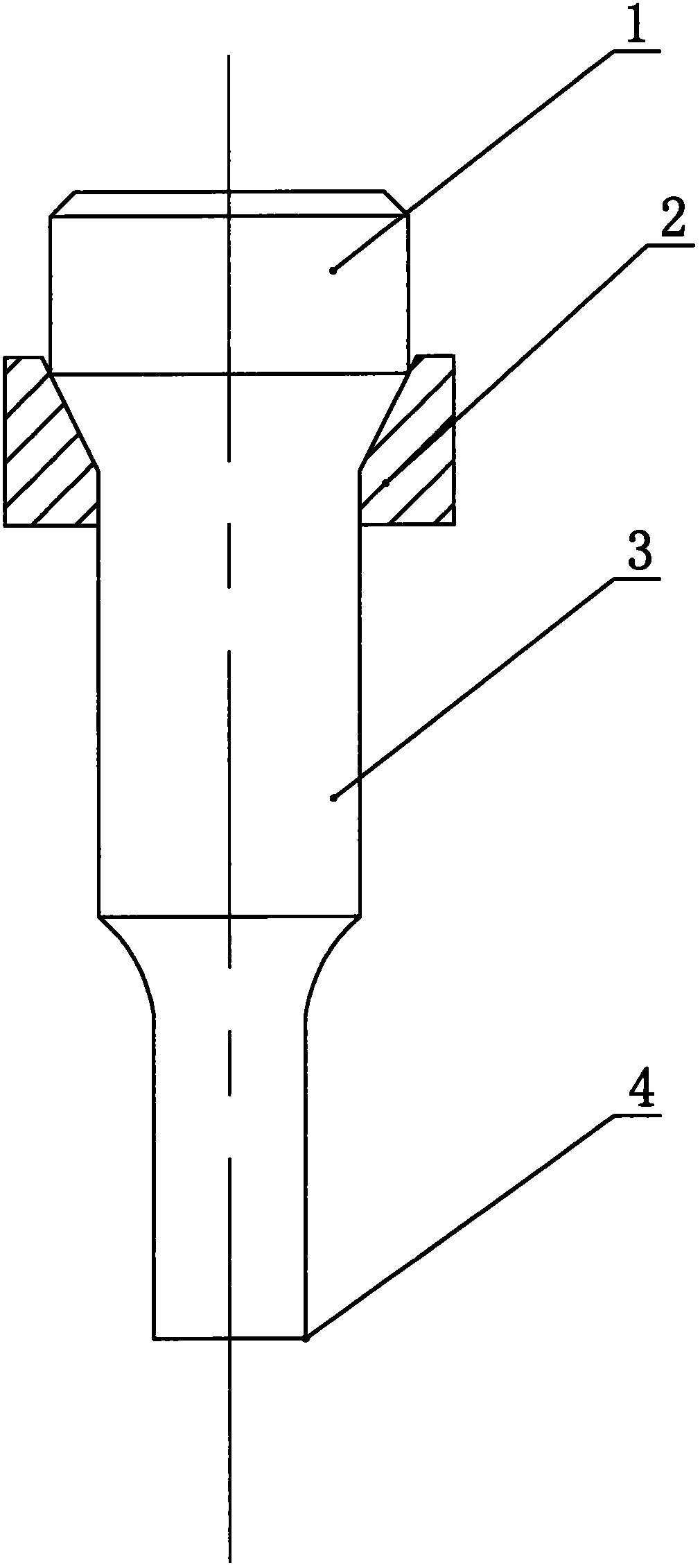

[0010] As shown in Figure 1, it is the inclined shoulder type punch of the present invention; comprise punch head 1, punch bar 3 and cutting edge 4, establish transitional inclined shoulder between punch head 1 and punch bar 3; For the convenience of punch The fixed installation of the slanted shoulder is equipped with a tapered ring 2; in order to prevent the axial core of the punch from being misaligned, the punch is damaged due to the application of external torque, and the top surface of the punch head 1 becomes an inclined surface.

[0011] In the oblique shoulder type punch structure of the present invention, a transitional oblique shoulder is set at the filtering place between the punch head 1 and the punch rod 3, which can prevent the punch head 1 from being damaged due to stress concentration, and does not need to increase the outer surface of the punch head 1. The size of the diameter can make the installation structure of the punch compact and reduce the manufacturin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com