Fully-automatic pencil sharpener assembly machine

A pencil sharpener and assembly machine technology, applied in assembly machines, metal processing, metal processing equipment, etc., can solve the problems of blade deviation, inability to place the knife shell accurately, and achieve the effect of accurate placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 — Figure 10 ;

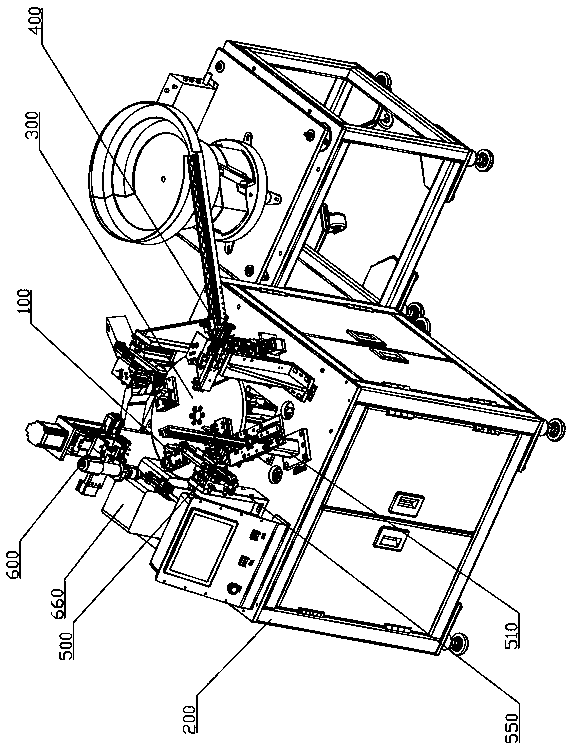

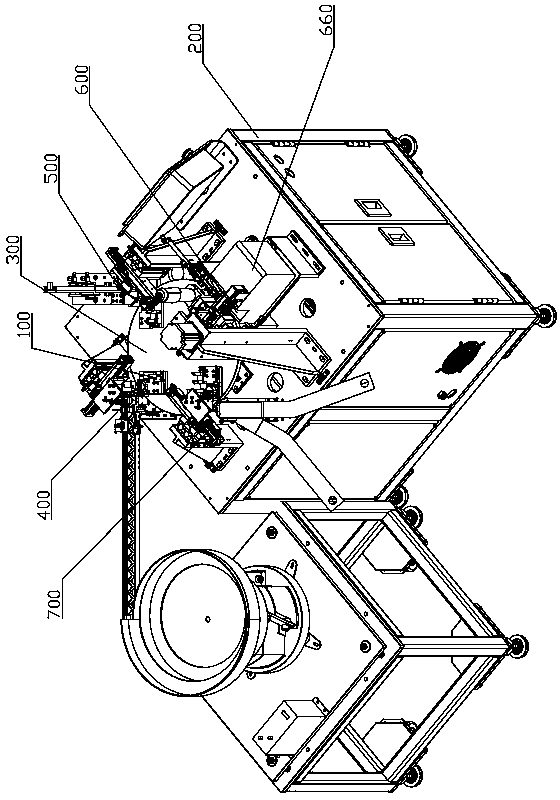

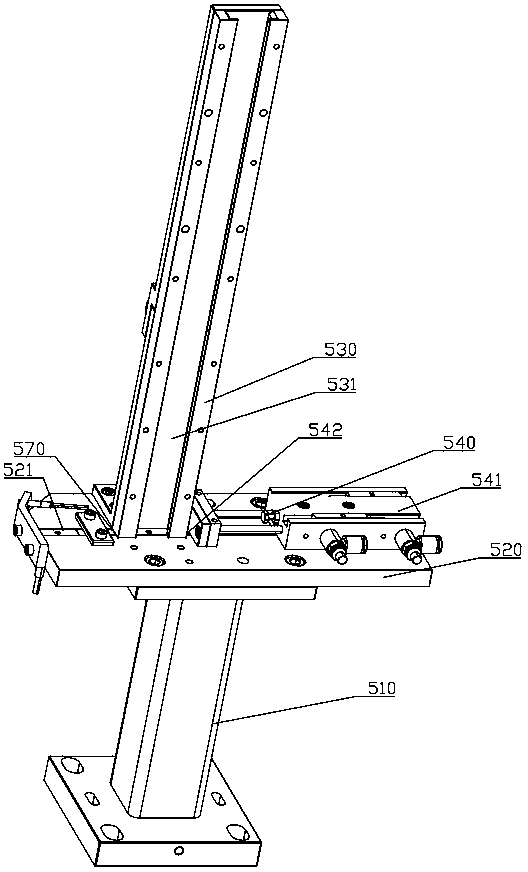

[0027] The fully automatic pencil sharpener assembly machine provided in this embodiment includes a frame 200, a turntable 300 that can rotate intermittently, a clamp 100 for clamping the pencil sharpener housing, a pencil sharpener housing supply device 400, a blade The supply device 500 , the screw fastening device 600 and the pencil sharpener discharge device 700 . The automatic pencil sharpener assembly machine adopts PLC control system to realize automatic assembly of pencil sharpeners. The PLC control system can also monitor the integrity of the pencil sharpener housing, whether the blade is installed on the pencil sharpener housing and whether the screw is used to fasten the blade on the pencil sharpener housing by means of sensors, and these monitoring The information is used as the basis for screening the fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com