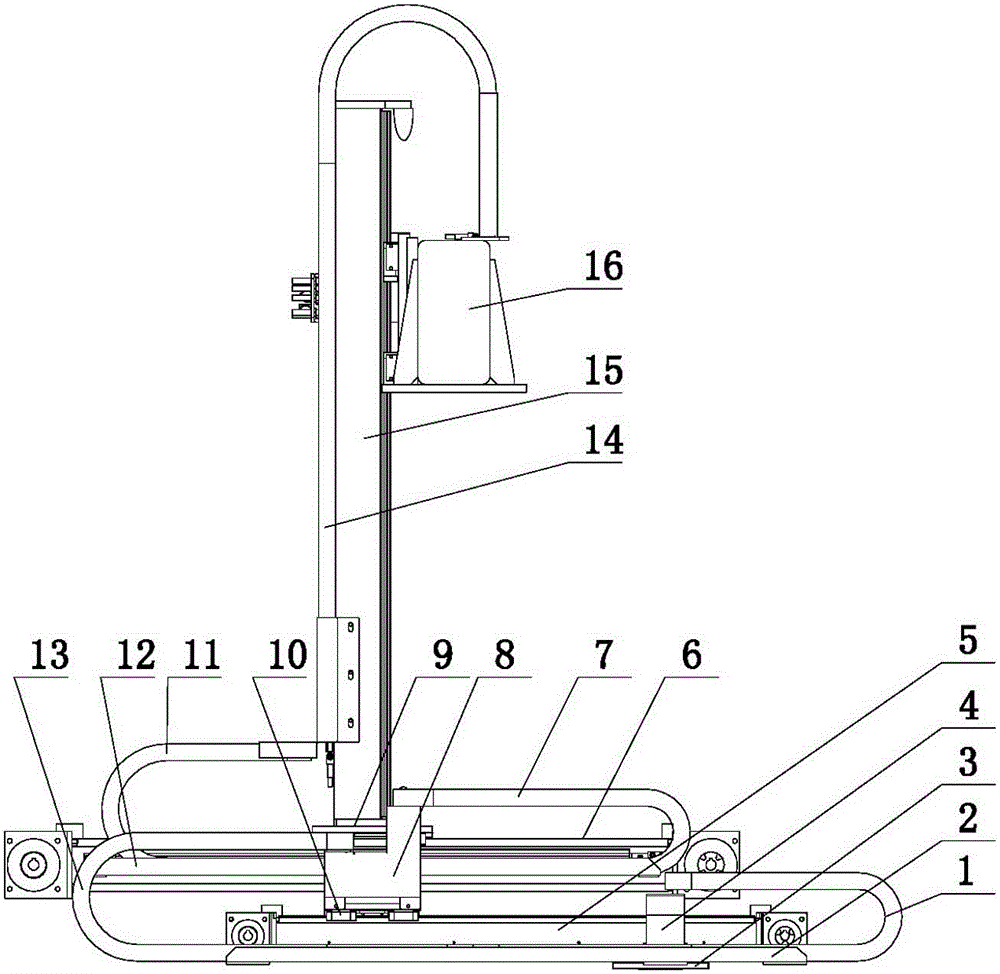

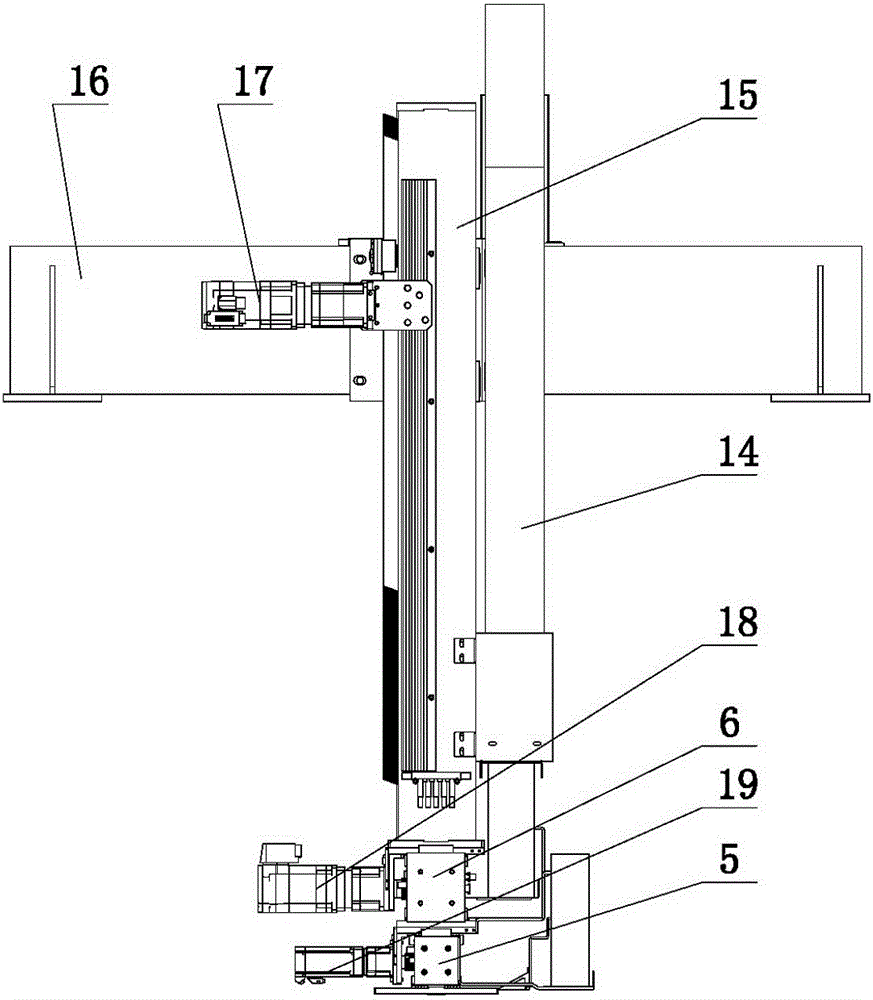

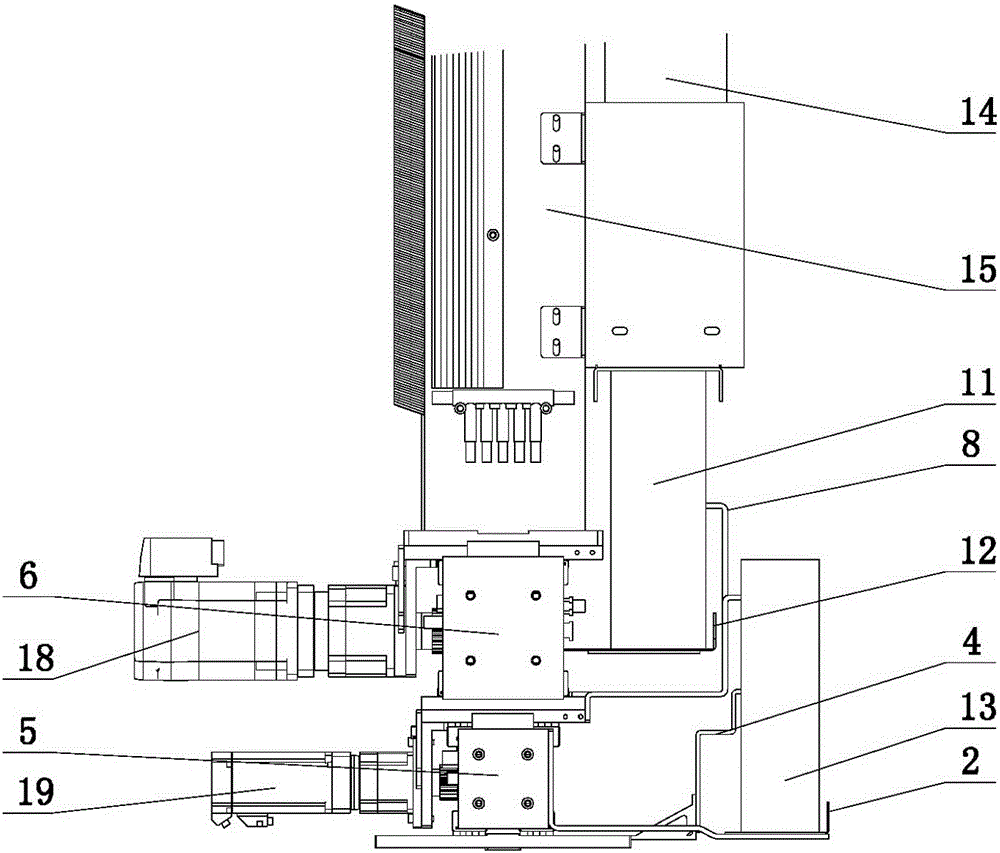

Press four-arm manipulator

A manipulator and articulated arm technology, which is applied in the field of four-arm manipulators of presses, can solve the problems of short running time at constant speed, long occupation time, and low work efficiency, and achieve the effects of reasonable layout, increased wear, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention includes a column 15 connected to a vertical driving device 17, and is characterized in that: the lower end of the column 15 is provided with a first-level crossbeam 6 through a first-level upper slider 9, and the first-level upper slider 9 is provided with a first-level drive for a first-level crossbeam 6 Device 18; the first-level crossbeam 6 is provided with a first-level synchronous belt 21 fixedly connected with the first-level upper slider 9; the first-level lower slider 10 connected with the same level of synchronous belt 21 is arranged below the first-level crossbeam 6 , the first-level lower slider 10 is connected with the second-level beam 5; the first-level lower slider 10 is provided with a secondary driving device 19 for the second-level beam 5, and the second-level lower slider 10 is provided with the same-level lower slider 10 to fix The connected secondary synchronous belt; the secondary lower slider 3 connected with the secondary sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com