Step-by-step teaching robot based on motor power and control method thereof

A teaching robot and motor-assisted technology, applied in computer control, manipulator, program control, etc., can solve problems such as high requirements for detection systems and computing systems, lag, and inability to eliminate the movement resistance of multi-joint arms in time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

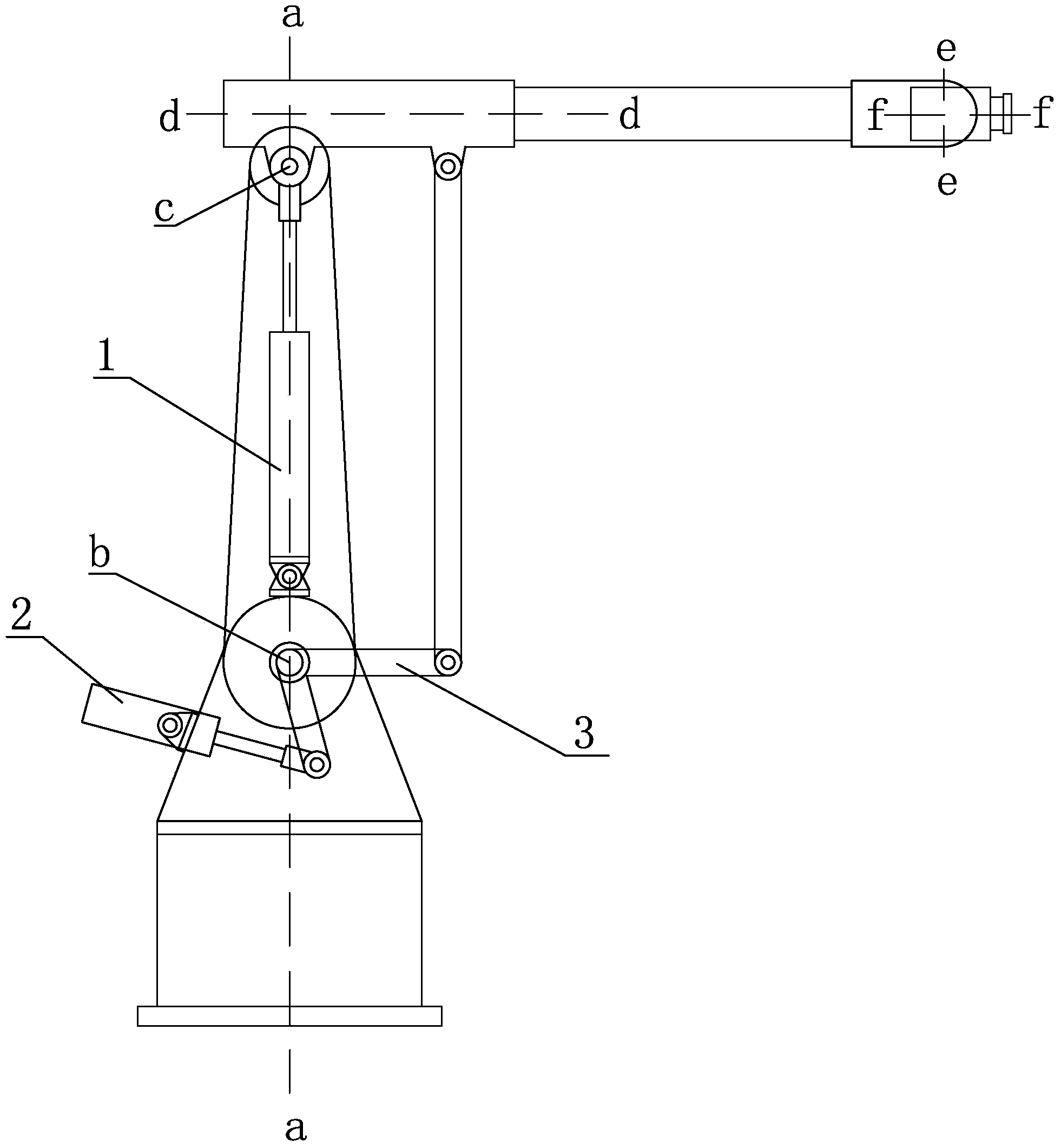

[0025] refer to figure 1 , the hand-held teaching robot based on motor assistance includes a large arm seat supported on the base that can rotate around the vertical axis a-a (J1 joint axis), supported on the large arm seat and can swing back and forth around the axis b (J2 joint axis) Boom, supported on the forearm seat that can swing up and down around the axis c (J3 joint axis), installed in the forearm seat, and can rotate around its axis d-d (J4 joint axis), installed at the end of the forearm The wrist swing section that can swing around the axis e-e (J5 joint axis) is installed on the wrist swing section that can rotate around the axis f-f (J6 joint axis) and is used for installing tools.

[0026] The first cylinder 1 is installed on the big arm seat, one end of which is hinged with the big arm seat, and one end of the piston rod is hinged with the supporting shaft of the small arm seat for the balance of the big arm. When the boom rotates to a certain position, the pu...

Embodiment 2

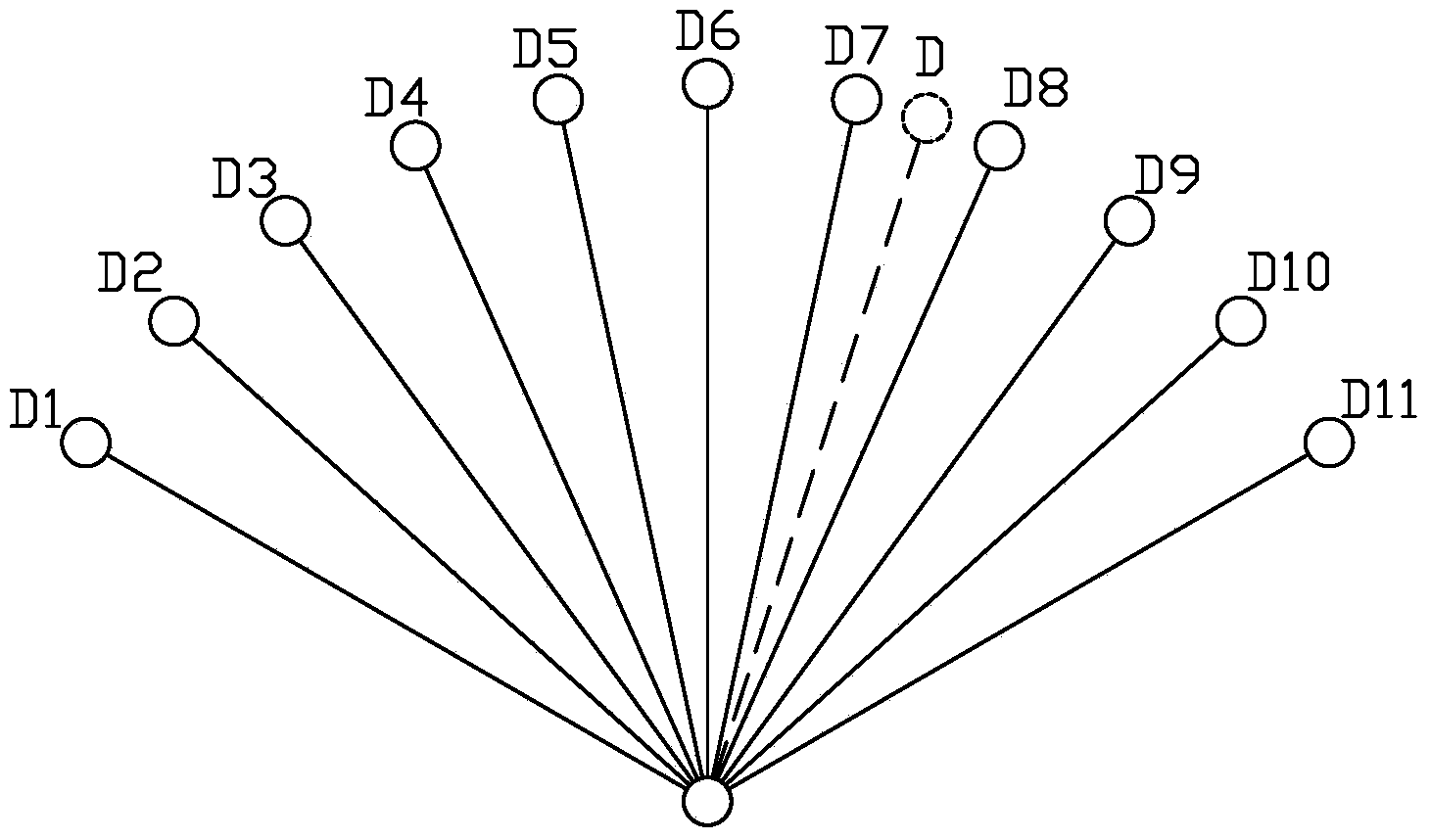

[0033] The magnitude of the assisting torque can be obtained through prior measurement. One of the measurement methods is, for a certain joint axis, apply different torques to the motor at a certain position, and it can be obtained that the joint axis is in the positive direction or the reverse direction at this position. The critical balance moment value just at rest is used as the positive or reverse assist torque value of the joint at this position. By measuring several positions in this way, a power-assisted calculation system associated with the pose of the multi-joint arm can be established. When teaching and controlling, the power-assisted torque required for the joint axis at a specific position can be obtained by searching and interpolating in the power-assisted calculation system. .

[0034] Taking the big arm as an example, although the function of being dragged and taught can be achieved through the balanced design, due to its heavy load, the frictional resistance ...

Embodiment 3

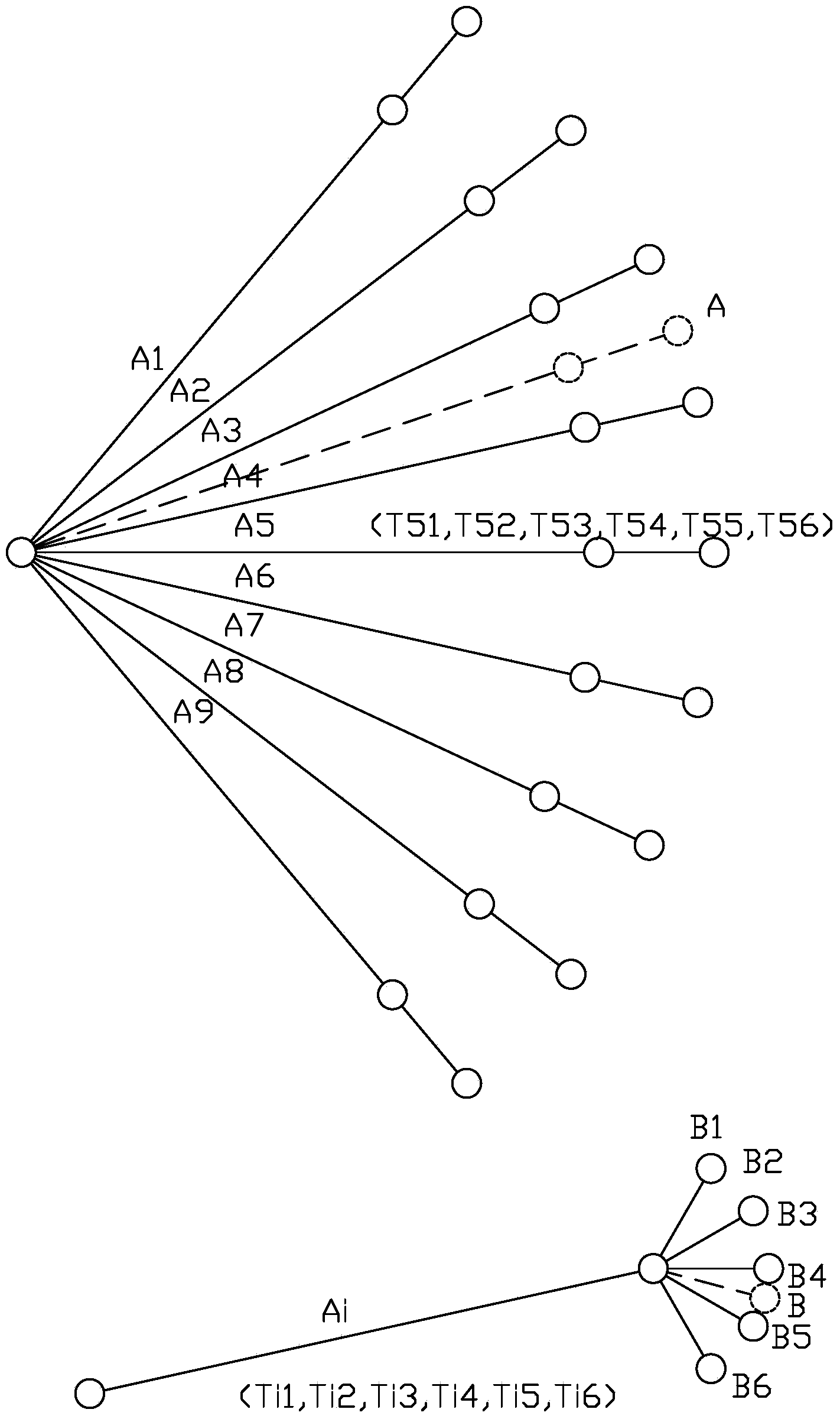

[0037] The balance state of the front-end joint axis is usually related to the posture of the rear-end joint. For example, the J5 joint axis will affect the J3 joint axis. When the influence is not large, it can be ignored for simplifying the processing, and it is enough to only deal with it according to the method of embodiment 1; when this influence needs to be considered, it is necessary to calibrate a certain position of the corresponding front joint axis when the rear joint axis is at The critical balance torque at different positions is obtained from a set of multivariate data. During the teaching control, the determined assist torque should be obtained according to the actual position data of the relevant joint axes.

[0038] Taking the J3 joint axis on the forearm as an example, considering the influence of the posture of the wrist swing segment on the forearm, the influence is more obvious when the load is large and the center of gravity is far away. The calibration met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com