Air volume control device and method for mercury catalyst drying systems

A drying system and air volume control technology, applied in the direction of drying gas arrangement, separation method, drying solid materials, etc., can solve the problems affecting power consumption, product quality of baking time, total increase of heavy metal pollution discharge, human body and environmental hazards, etc. problems, to achieve the effects of shortening baking time, good economic and social benefits, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

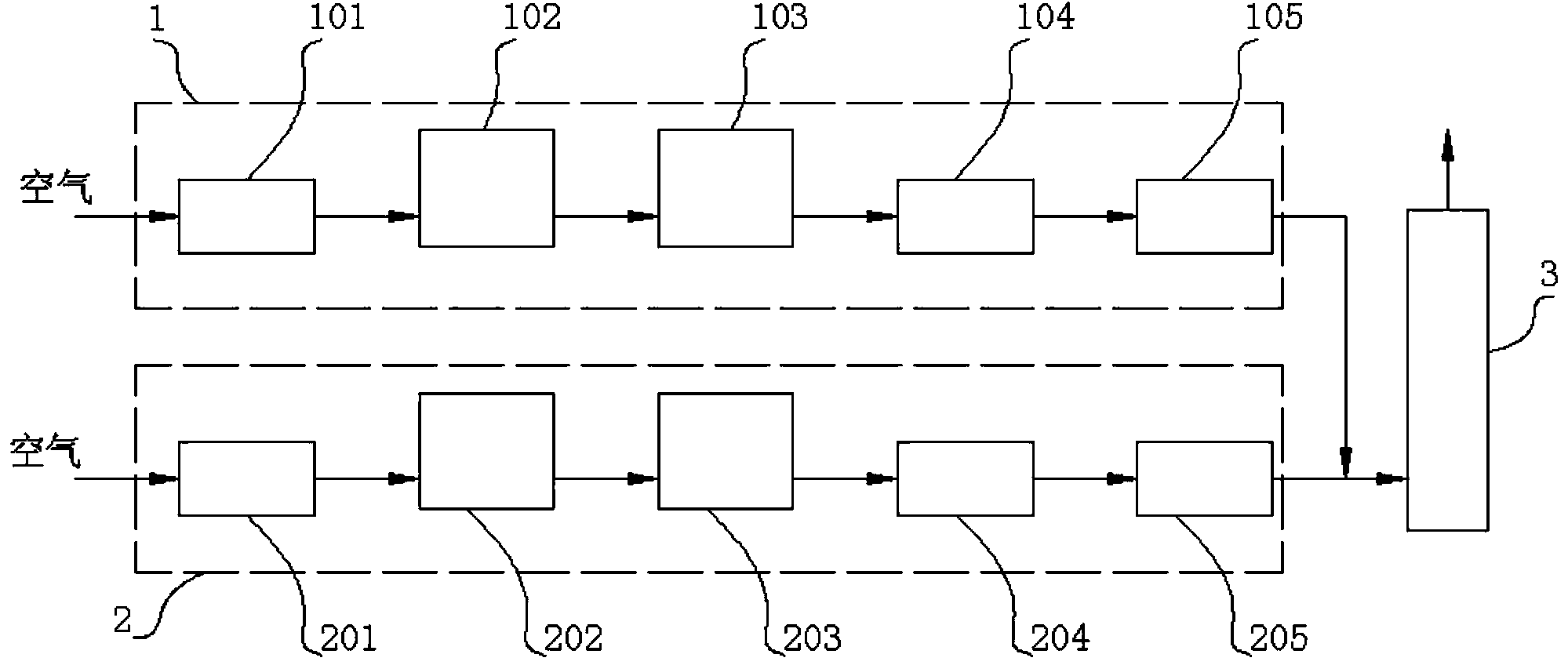

[0021] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

[0022] Such as figure 1 As shown, a mercury catalyst drying system air volume control device according to the present invention includes a settling system 3 and a drying system A1 and a drying system B2 arranged in parallel. , drying furnace A103 and pre-drying furnace A104, and an induced draft fan A105 is connected to the outlet of the pre-drying furnace A104; the drying system B2 is composed of a blower B201 connected in sequence, an electric heating furnace B202, a drying furnace B203 and a pre-drying furnace B204 A fan B205 is connected to the outlet of the pre-drying furnace B204, and the outlets of the fan A105 and the induced draft fan B205 are connected to the settling system 3 respectively. The settling system 3 includes a first-stage activated carbon adsorption tower, a seco...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap