High-sensitivity multi-parameter explosion-proof type infrared gas sensor

A gas sensor and high-sensitivity technology, applied in the field of sensors, can solve the problems that the incident angle of light does not meet the design requirements of the detector, cannot meet the application fields of high precision and multi-parameters, and cannot be made into practical products, etc., to achieve guaranteed performance , Prevent the influence of water vapor, the effect of scientific structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

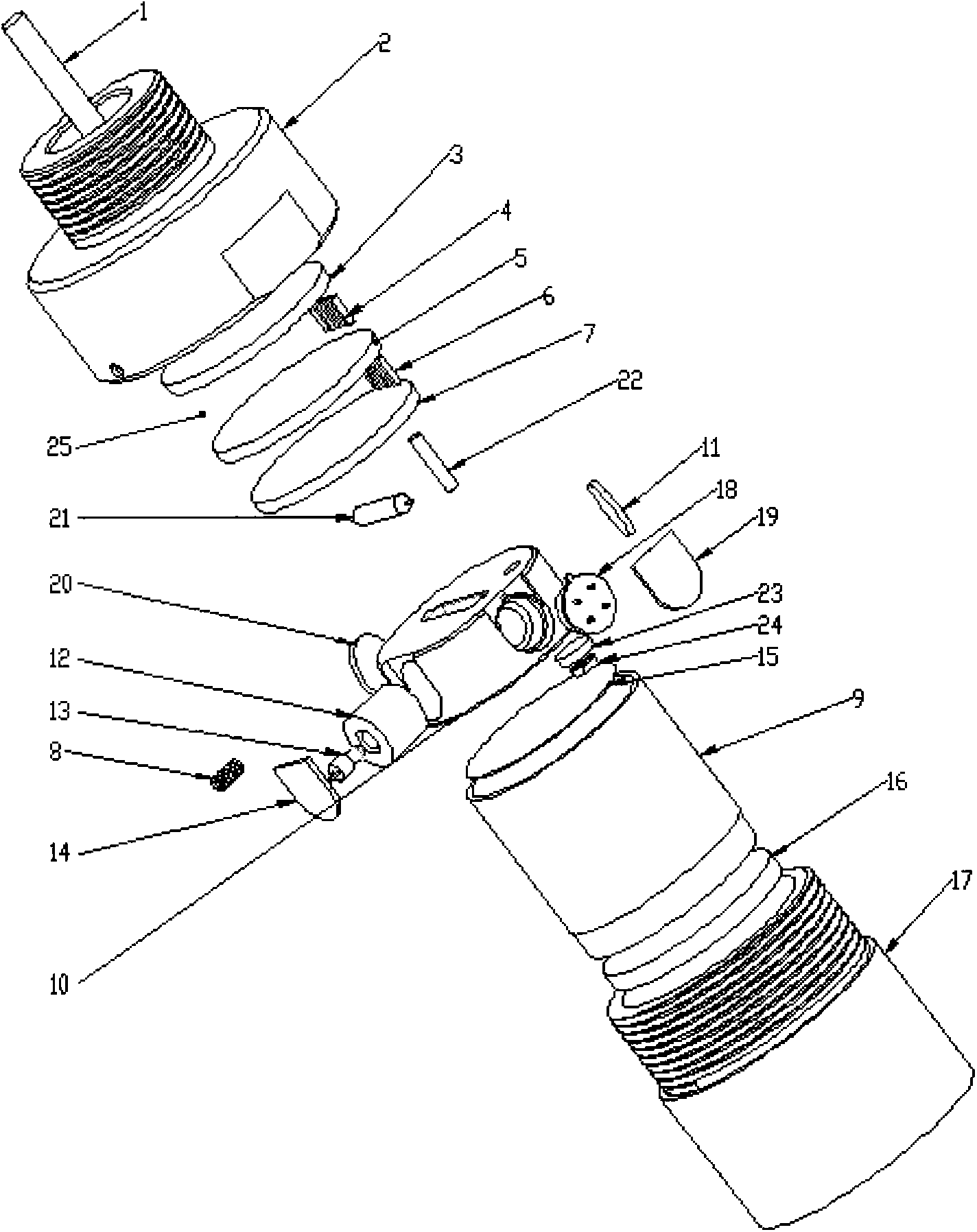

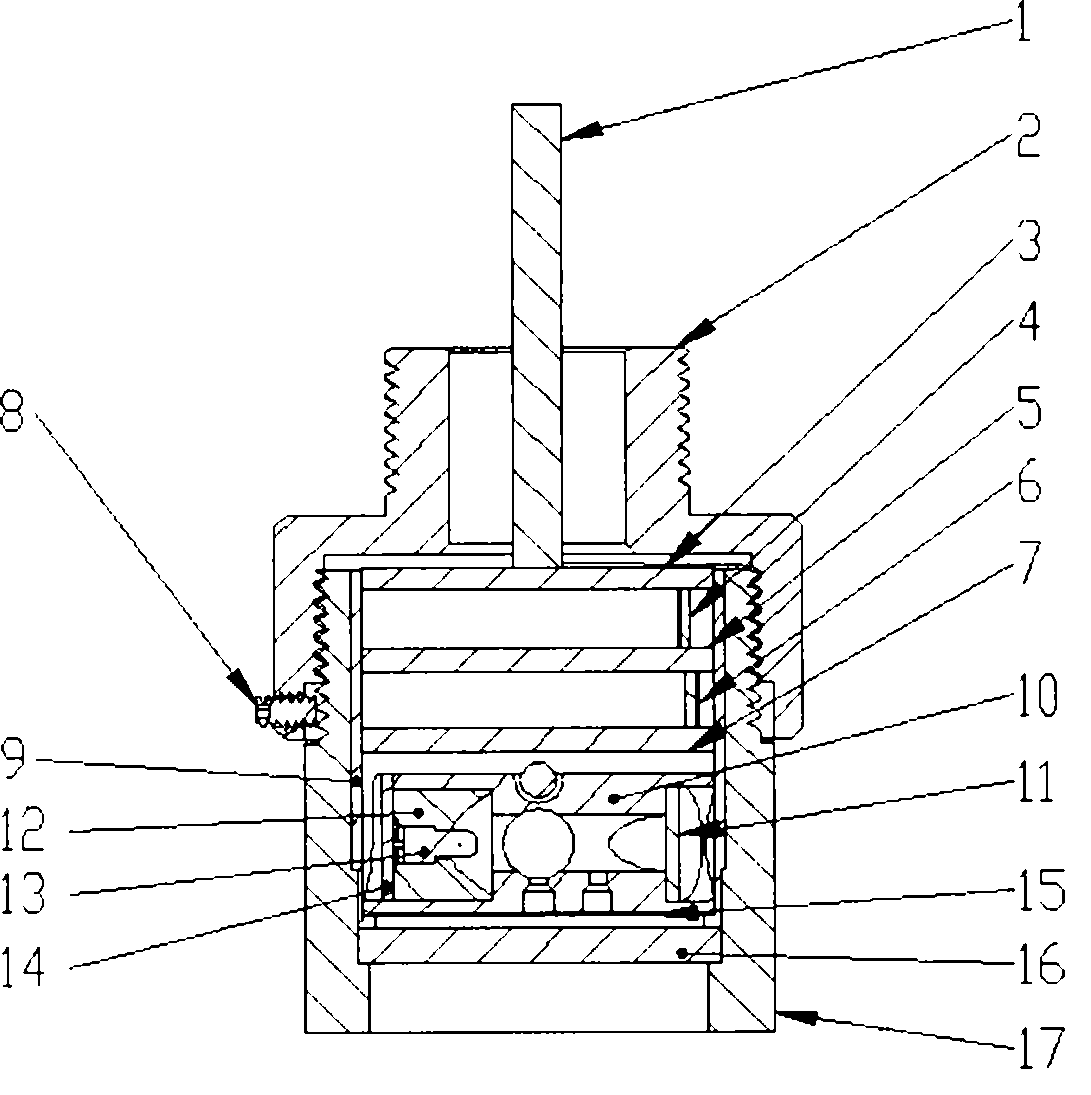

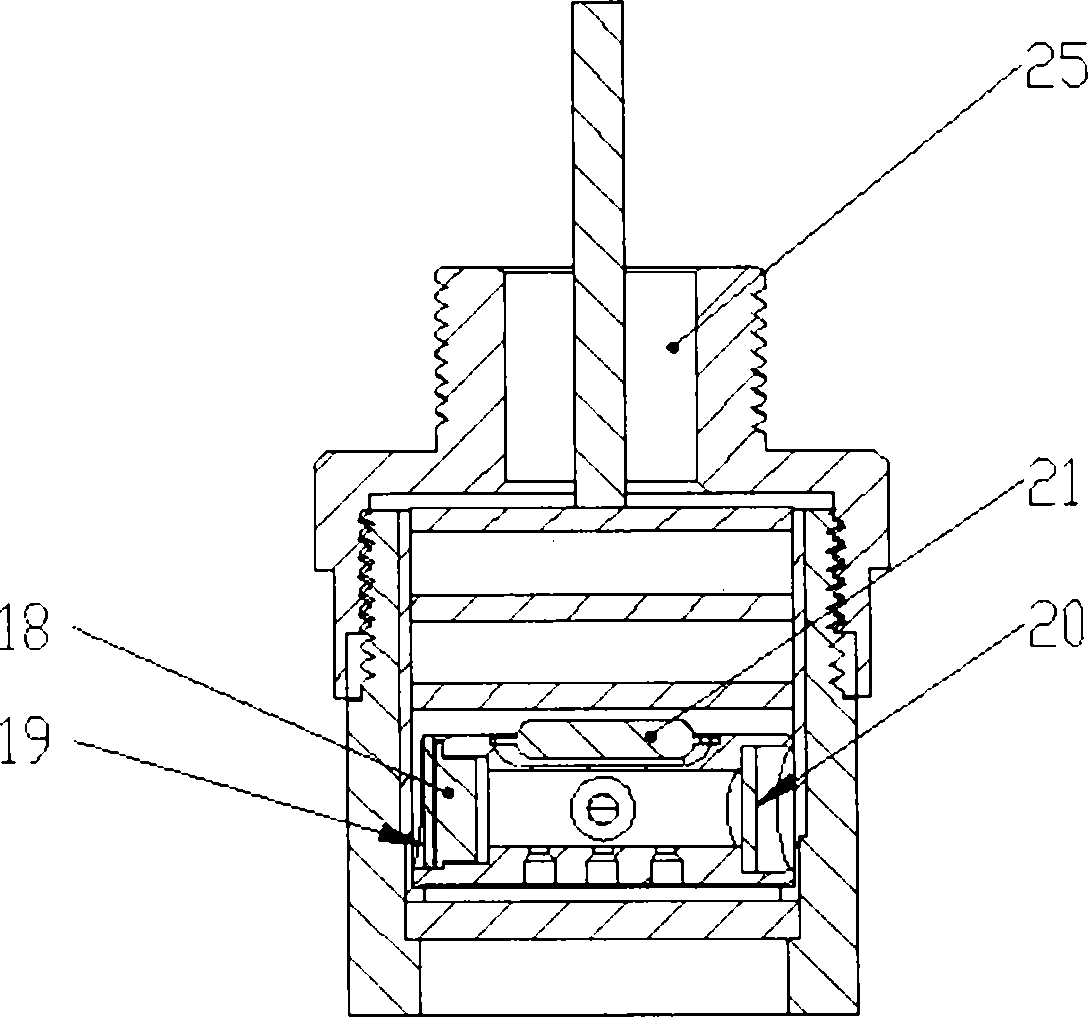

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0024] Such as Figure 1-5 As shown, a high-sensitivity multi-parameter explosion-proof infrared gas sensor, the sensor includes an explosion-proof shell 17, an explosion-proof plate 16, an explosion-proof base 2, a power supply data line 1, and a set screw 8 is installed on the explosion-proof base 2; Optical cavity 10 and circuit board 3, main circuit board 5, analog circuit board 7, small light board 14, detector circuit board 19, temperature and humidity sensor circuit board 23; Light source 13; the top of the optical cavity 10 is provided with a waterproof breathable film 15, the circumference is provided with an insulating sleeve 9, the inside of the optical cavity 10 is provided with a temperature and humidity sensor 24, and the bottom of the optical cavity 10 is provided with a power resisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com