A detection device for surface defects of curved workpieces

A technology of a curved workpiece and a detection device, which is applied in the direction of optical testing of flaws/defects, can solve the problems of complex operation of the detection structure and huge system, and achieves the effects of good portability, simple operation and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

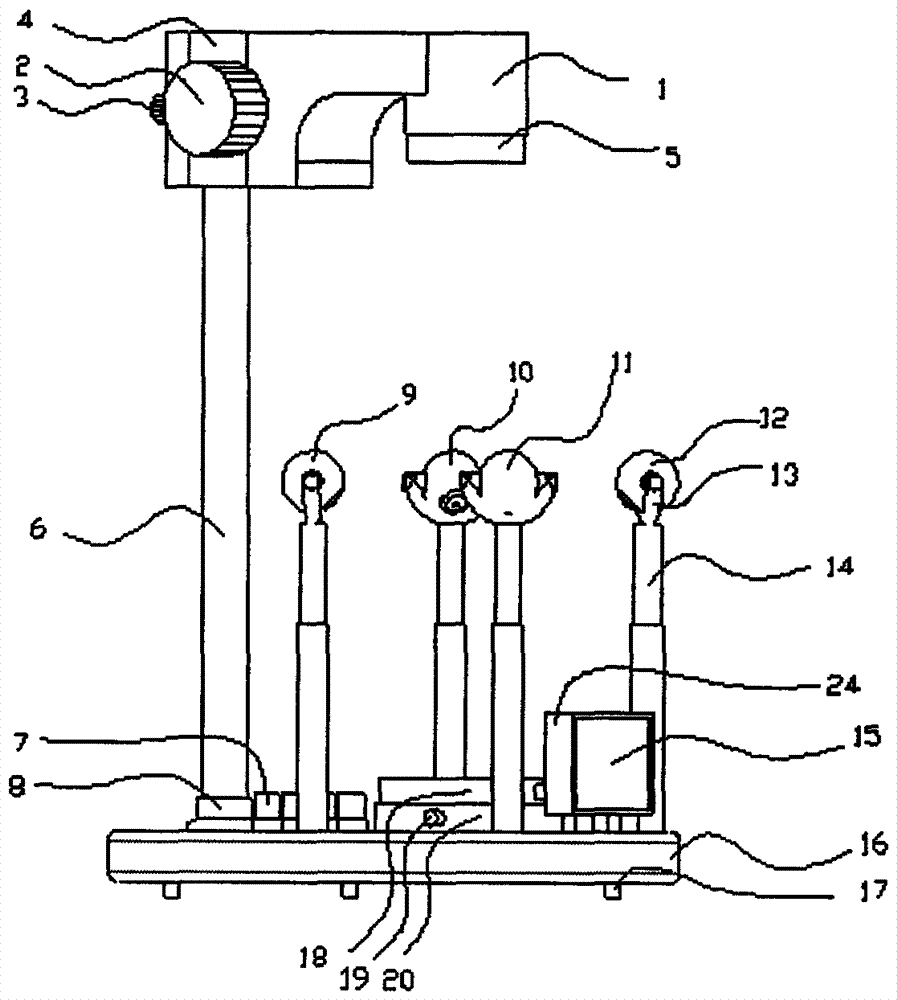

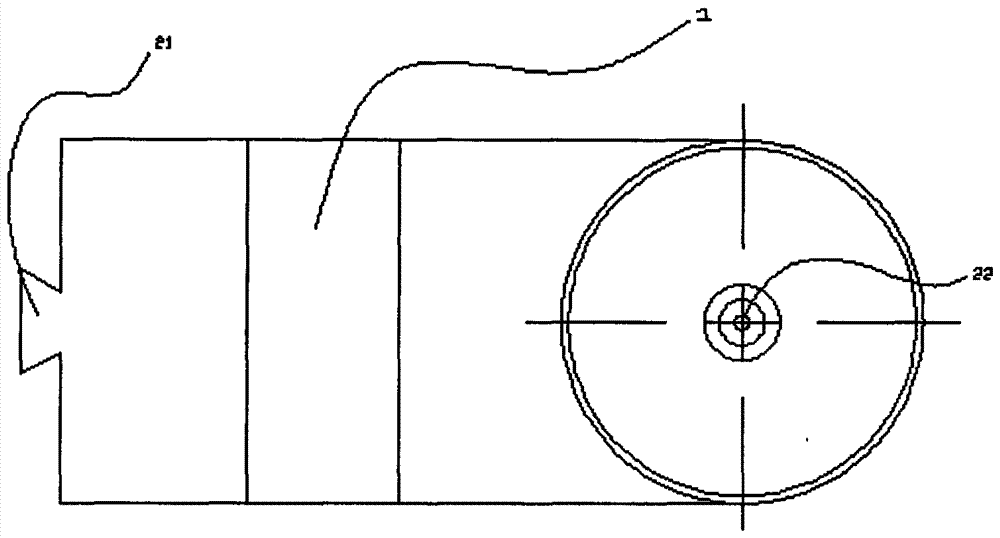

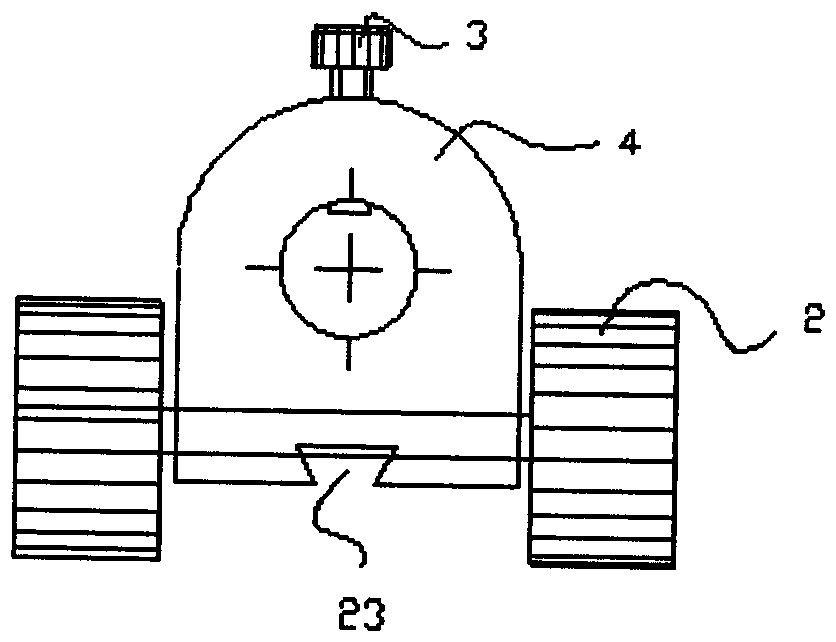

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a detection device for surface defects of curved surface workpieces of the present invention includes a micro digital zoom microscope system 1, the micro digital zoom micro system 1 is a cuboid with one side cut by a cylinder, and an image acquisition camera 22 is arranged in the center of the top , the connection card slot 21 on the miniature digital zoom microscope system 1 matches the connection gap 23 on the card slot type connection sleeve 4. When collecting images, it is necessary to turn the zoom knob 5 to adjust the definition of imaging.

[0026] The micro digital zoom micro system 1 is connected to the chassis 16 through the support rod 6, and the height of the micro digital zoom micro system 1 can be adjusted by coarsely adjusting the rotating handle 2 and finely adjusting the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com