Object image shooting and splicing method

An image and object technology, applied in the field of shooting and stitching object images, can solve problems such as distortion, and achieve the effect of accurately stitching images

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

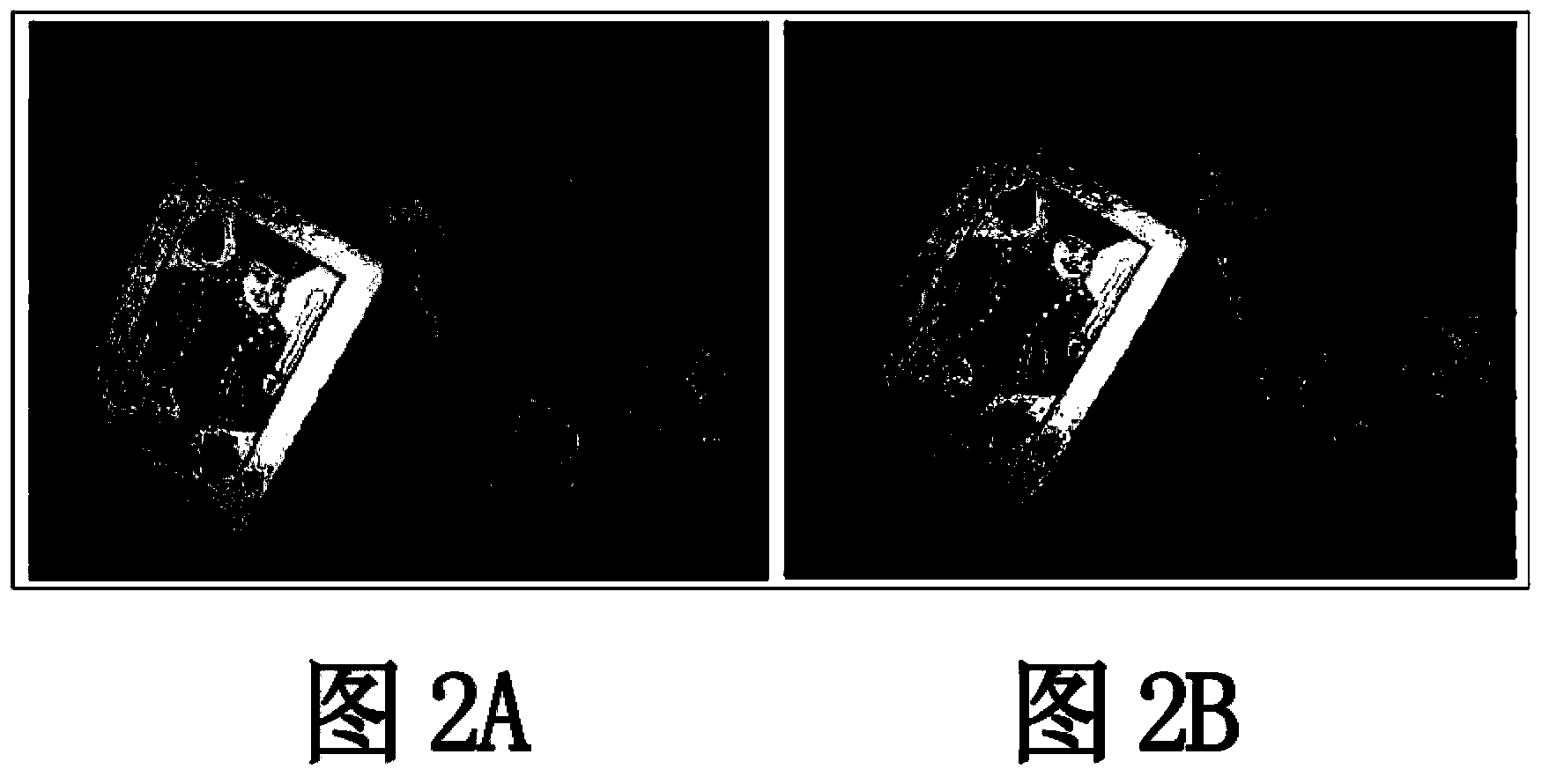

[0040] The invention provides a method for shooting and splicing object images. This method is to determine the real coordinates of the photographed object according to a real space coordinate system, and set different image coordinate systems for the images of different regions of the photographed object. Then, by finding the coordinate correspondence between each image coordinate system and the real space coordinate system, the relative positions among multiple images are determined. In this way, multiple images can be effectively spliced and combined to obtain a complete image of the captured object.

[0041] Please refer to Figure 4 , which shows the flow of a method for shooting and stitching object images provided by the present invention.

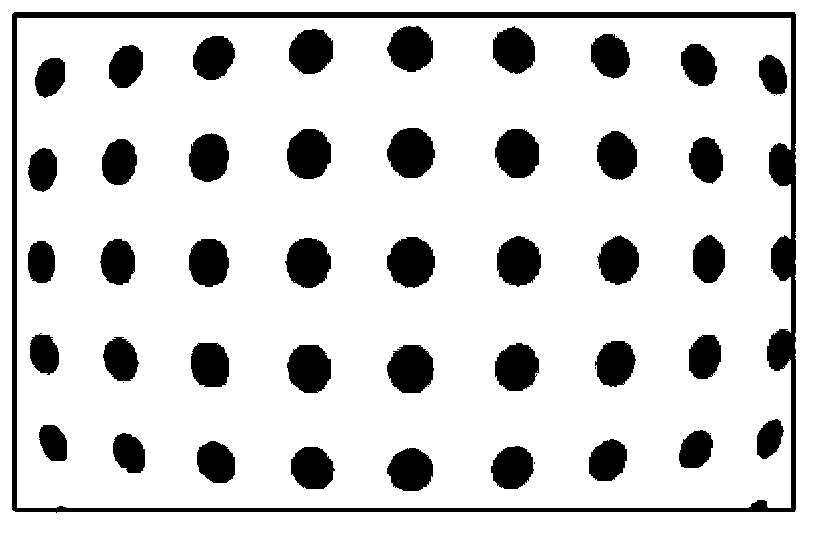

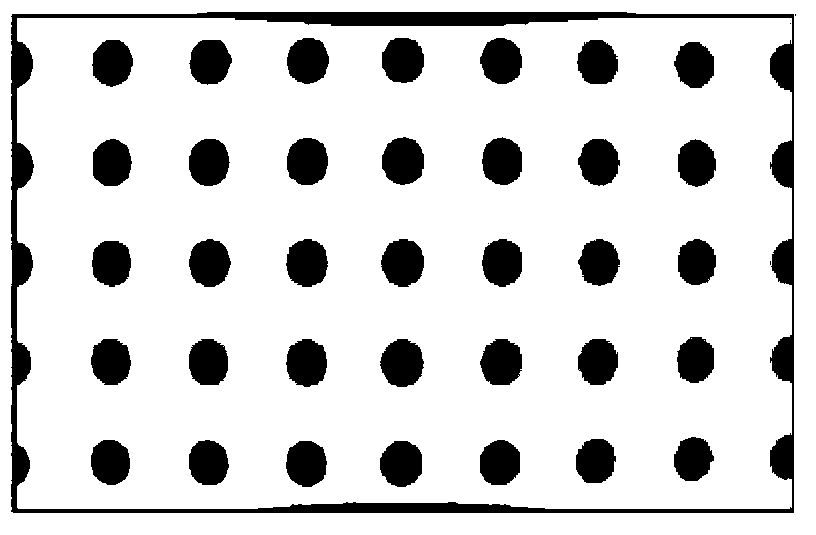

[0042] First, step S01 is executed to set up multiple cameras above a working platform. Multiple cameras can be set up at different heights, and the lenses of the cameras can be adjusted separately to have different focal lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com