sliding member

A sliding member and sliding layer technology, applied in the direction of engine components, sliding contact bearings, rotating parts resistant to centrifugal force, etc., to achieve the effect of inhibiting sticking, ensuring wear resistance and excellent performance

Active Publication Date: 2015-08-26

SENJU METAL IND CO LTD

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, when the sliding surface is made smooth, although the frictional resistance can be suppressed low, the sliding surface will generate some heat, and therefore, there may be a problem caused by so-called burning. to fix (Japanese: to fix)

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

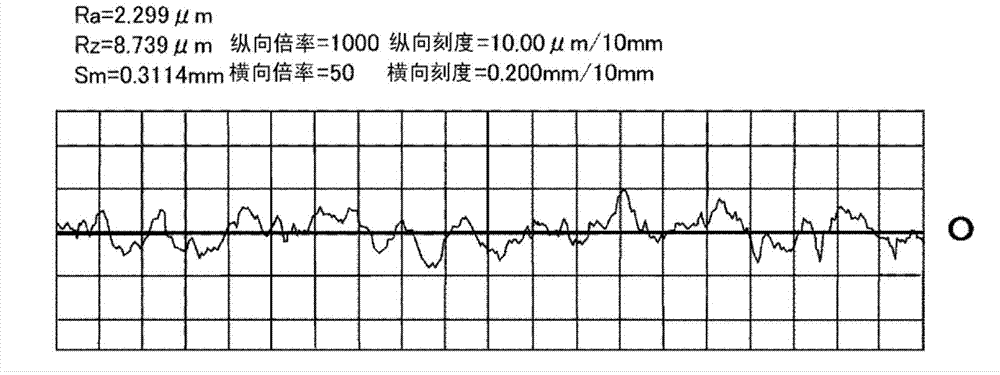

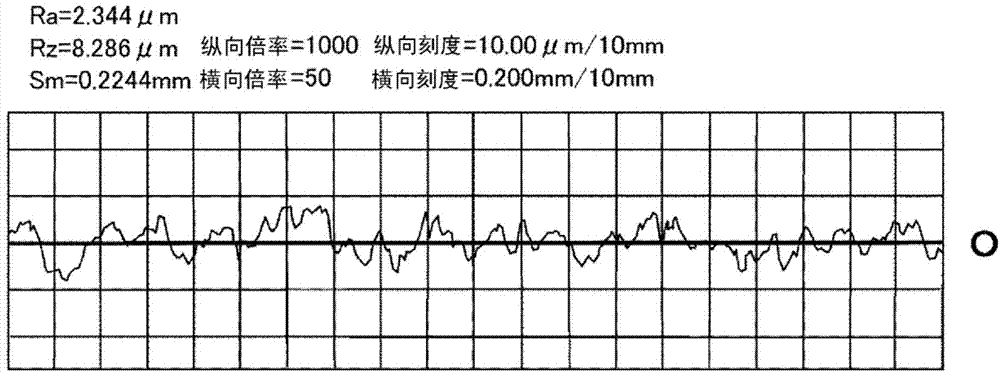

[0066] (1) With or without shot blasting and the shape of the sliding surface

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Login to View More

Abstract

To provide a sliding member which has hardness that is suitable for the circumstance, to which heavy load is applied, and which is excellent in abrasion resistance property. The sliding member contains a sliding layer for slidably supporting a body to be slid, shot blasting being performed on a surface of the sliding layer, and a sliding surface formed on a surface of the sliding layer, the sliding surface having an uneven configuration with arithmetic mean roughness (Ra) of 1.0 µm through 2.5µm, 10-point average roughness (Rz) of 5.0 µm through 10.0µm, and surface hardness (Hv) of 220 through 250.

Description

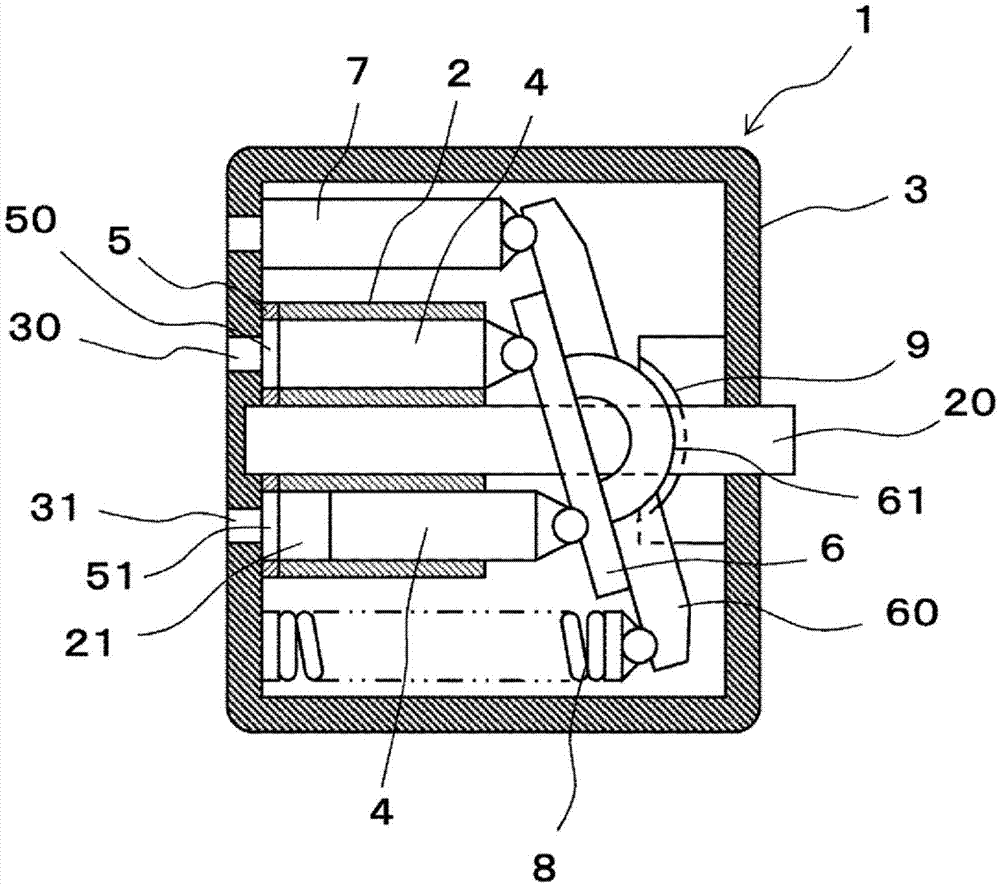

technical field [0001] The present invention relates to a sliding member for supporting an object to be slid so that the object to be slid can be slid. Background technique [0002] Generally, in order to reduce friction, the sliding surface is desirably smooth. However, when the sliding surface is made smooth, although the frictional resistance can be suppressed low, the sliding surface will generate some heat, and therefore, there may be a problem caused by so-called burning. To fix (Japanese: condense). Therefore, the sliding surface is required to have an appropriate surface roughness. [0003] Conventionally, the technique of forming recesses by shot blasting the sliding surface is known, and a technique of forming an oil reservoir on the sliding surface of a sliding member by shot blasting is known (for example, refer to Patent Document 1). [0004] Patent Document 1: Japanese Patent No. 4848821 Contents of the invention [0005] The problem to be solved by the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F16C33/12F04B53/18F16C33/14F16C33/20F16J1/02

CPCF16C2223/08F16C2240/54F16C17/02F16C33/14F16C2204/10F16C2202/04F16C33/20F04B1/2021F16C33/10F16C33/12F04B1/2028F01B3/0073F16C2204/12F16C2360/00F16C2240/48F16C17/04F16C2240/40

Inventor 佐藤直树仓田良一

Owner SENJU METAL IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com