Power box used for automatic feed transferring

A power box and automatic technology, which is applied in the field of power box for automatic feed transmission, can solve the problems of easy jamming and unstable output of the power device, and achieve the effects of improving labor productivity, reducing pollution and increasing investment income.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

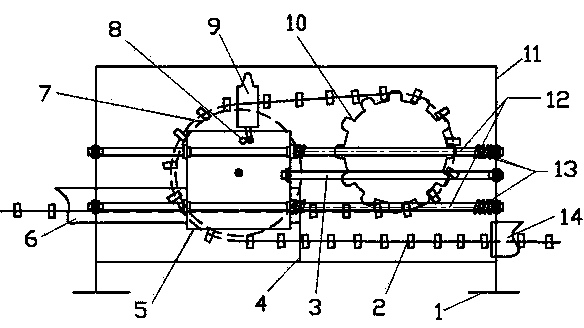

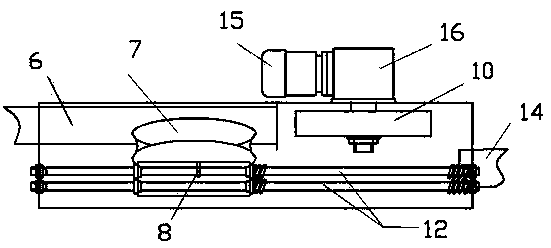

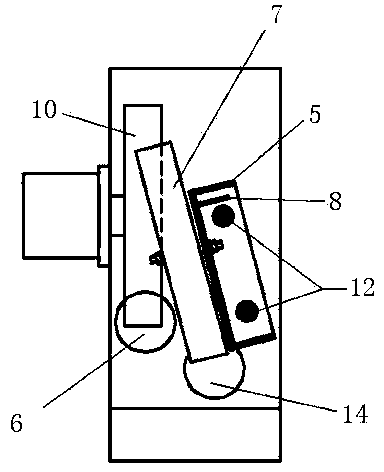

[0013] refer to Figure 1 to Figure 4 , a power box for automatic feeding provided by the present invention, the box body 11 is equipped with a transmission mechanism that drives the scraper chain 2 to form a circular transmission, and the scraper chain 2 cooperates with the delivery pipe outside the box to pass through the hopper From the conveying pipe to the feeding trough of the breeding house, the transmission mechanism includes a transmission gear 10 installed in the box body 11 for driving the transmission of the scraper chain 2 and a tension wheel 7 for adjusting the tension of the scraper chain 2, the axis of the transmission gear 10 Parallel to the horizontal plane, and the axis of the tension wheel 7 forms an inclination angle of 18 degrees with the horizontal plane, wherein the tension wheel 7 is installed on the connecting plate 5, and the connecting plate 5 is installed on two positioning rods 12 through a sliding joint and positioned The helical spring 13 that r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com