An adsorbent for removing beta-2 microglobulin from blood

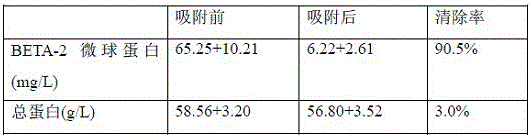

A technology of BETA-2 and microglobulin, which is applied in the field of adsorbents for removing BETA-2 microglobulin in blood, can solve the problems of poor adsorption selectivity of BETA-2 microglobulin, and achieve excellent adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The preparation of embodiment 1 highly cross-linked macroporous microspheres

[0022] At room temperature, dissolve 10g of gelatin in 1000ml of water to make a 1.0% (mass fraction) aqueous solution, place it in a 2000ml three-necked flask and heat it to 45°C to fully dissolve the gelatin; mix 50g of styrene, 100g of divinylbenzene , 0.3g polylysine, 99.7g toluene, 200g gasoline (No. 200 gasoline) and 1.5g azobisisobutyrocyanide were mixed evenly, then added to the three-necked bottle, started to stir, and adjusted the speed to disperse the oil droplets, and after suspension Polymerization, slowly heat up to 78°C at a speed of 1-2°C / 5 minutes, react for 3 hours, then slowly heat up to 85°C at a speed of 1-2°C / 5 minutes, react for 3 hours, and then heat up at a speed of 1-2°C / 5 minutes Slowly raise the temperature to above 95°C at a speed of 5 minutes, react for 5 hours, then stop the reaction, filter and wash, and prepare cross-linked polystyrene-divinylbenzene macroporo...

Embodiment 2

[0023] The preparation of embodiment 2 highly cross-linked macroporous microspheres

[0024] At room temperature, dissolve 12g of polyvinyl alcohol in 1200ml of water to make a 1.0% (mass fraction) aqueous solution, place it in a 3000ml three-neck bottle and heat it to 45°C to fully dissolve the polyvinyl alcohol; add 25g of styrene, 125g Divinylbenzene, 1.0g polylysine, 99g toluene, 25g liquid paraffin, 25g solid paraffin and 2.0g benzoyl peroxide were evenly mixed and then added to the three-necked bottle, started to stir, and adjusted the speed to disperse the oil beads, and suspended Polymerization, slowly heat up to 78°C at a speed of 1-2°C / 5 minutes, react for 3 hours, then slowly heat up to 85°C at a speed of 1-2°C / 5 minutes, react for 3 hours, and then heat up at a speed of 1-2°C / 5 minutes Slowly raise the temperature to above 95°C at a speed of 5 minutes, react for 5 hours, then stop the reaction, filter and wash, and prepare highly cross-linked polystyrene-divinylben...

Embodiment 3

[0025] The preparation of embodiment 3 highly cross-linked macroporous microspheres

[0026] At room temperature, dissolve 10g of polyvinyl alcohol in 1000ml of water to make a 1.5% (mass fraction) aqueous solution, place it in a 2000ml three-necked bottle and heat it to 45°C to fully dissolve the polyvinyl alcohol; dissolve 150g of divinylbenzene , 1.5g polylysine, 198.5g toluene, 125g liquid paraffin, 125g solid paraffin and 2.0g benzoyl peroxide were mixed evenly and then added to the three-necked bottle, started to stir, and adjusted the speed to disperse the oil beads. After suspension polymerization, the Slowly heat up to 78°C at a speed of 1-2°C / 5 minutes, react for 3 hours, then slowly heat up to 85°C at a speed of 1-2°C / 5 minutes, react for 3 hours, and then heat up at a speed of 1-2°C / 5 minutes Slowly raise the temperature to above 95°C, react for 5 hours, then stop the reaction, filter and wash to prepare highly cross-linked polystyrene-divinylbenzene macroporous mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com