A high-efficiency ultra-precision glass lens non-isothermal molding equipment and molding method

A technology of compression molding and glass lens, which is applied in precision molding, near-net shape, and ultra-precision processing fields. It can solve the problems of high manufacturing cost, long molding cycle, and short service life of workpieces, and achieve uniform center thickness and raw material utilization. Effects with high, high geometric precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

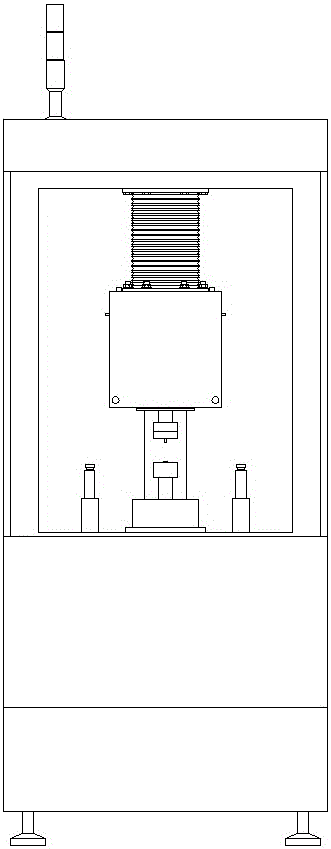

[0072] As shown in the figure, the device of the present invention includes a workbench, a lower mold base arranged on the workbench, an upper mold base matched with the lower mold base, an upper mold placed in the upper mold base, and a mold placed in the lower mold base. The lower mold, the pressurized platform, the vacuum cover connected with the pressurized platform, the vacuum connecting pipe connected with the vacuum cover, the vacuum device connected with the vacuum connecting pipe, the heater for heating the workpiece, the control system, The pan-tilt lifting device that can drive the pressurized pan-tilt up and down, the mechanical arm, the lifting and rotating device, the suction and release device for sucking and releasing the workpiece, the preheating device for preheating the workpiece, the cooling device, the clamping device, the connection Rod, the lower mold seat lifting device that can drive the connecting rod up and down. In this embodiment, the vacuum cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com