Rail fastener system without elastic strips

A technology of track fasteners and elastic strips, which is applied in the direction of tracks, roads, fixed rails, etc., can solve problems such as reducing the pressure of elastic strips, corrosion of iron backing plates, and easy breakage, so as to improve safety and reliability, and alleviate Corrosion problems, the effect of preventing left and right shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

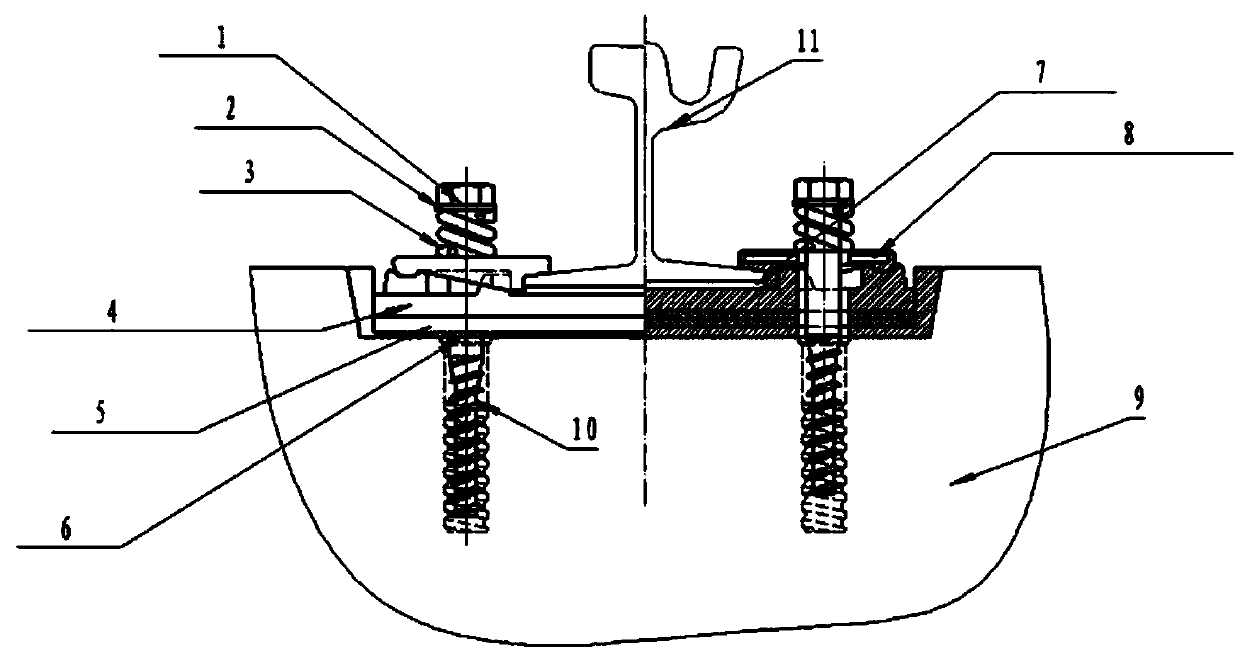

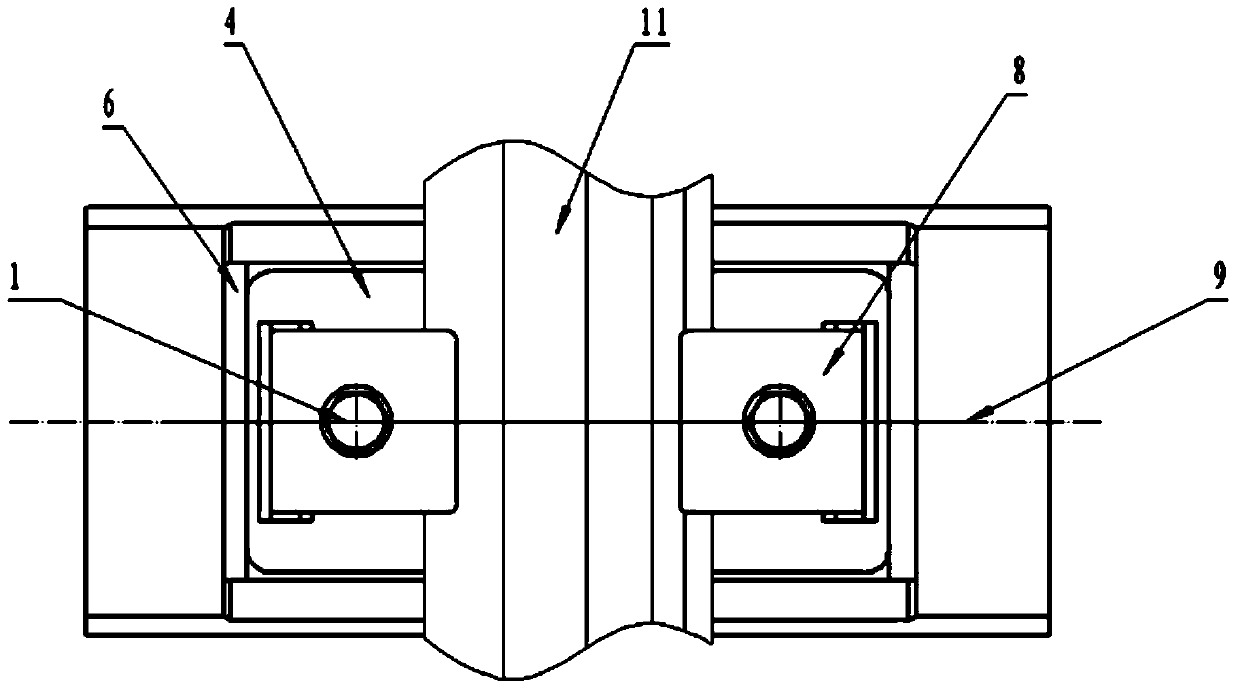

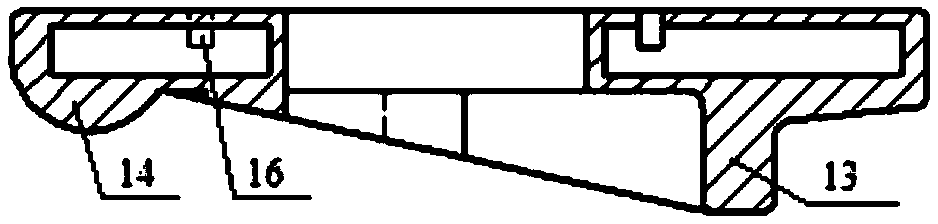

[0022] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the rail fastening system without elastic strips includes a gauge backing plate 6 with a concave vertical cross-sectional shape arranged in the groove of the concrete sleeper 9, and an elastic backing plate 5 under the board is arranged above the gauge backing plate 6. A backing plate 4 is arranged above the lower elastic backing plate 5, and two positioning blocks 12 are symmetrically arranged on the upper surface of the backing plate 4, and the under-rail backing plate 7 is arranged in the groove between the two positioning blocks 12, and the rail of the rail 11 The bottom is placed on the backing plate 7 under the rail. The size of the backing plate 7 matches the size of the bottom surface of the rail bottom of the rail 11. The lower surface of one end of the nylon gauge buckle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com