Engine timing encloser installation structure easy to assemble and disassemble

A timing cover and installation structure technology, applied in the direction of engine components, machines/engines, shells, etc., can solve the problems affecting the NVH quality of the engine, high maintenance costs, and easy resonance, etc., to improve NVH quality and high labor efficiency , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to enable those skilled in the art to better understand the technical solution, the present invention will be further elaborated below in conjunction with the accompanying drawings:

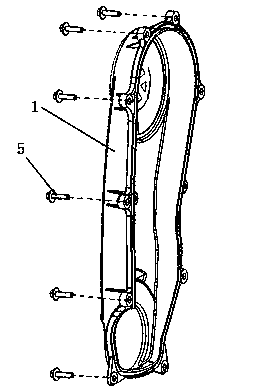

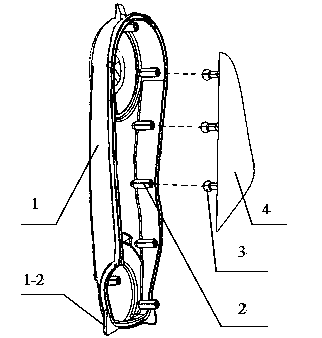

[0017] see figure 2 , is the timing cover installation structure proposed by the present invention, the timing cover 1 is installed on the cylinder block 4 through 10 buckle structures.

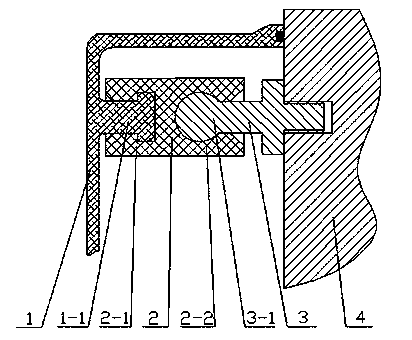

[0018] see image 3 , the timing cover 1 is formed by injection molding of plastic material, and 10 T-shaped chucks 1-1 are molded together at the inner edge of the cavity of the timing cover 1 during injection molding. Correspondingly, there are 10 ball studs 3 on the cylinder block. There are also 10 rubber connectors 2 for intermediate transition connections. The front end of the rubber connector 2 has a T-shaped slot 2-1, and the rear end has a ball joint slot 2-2. The T-shaped chuck 1-1 on the timing cover is engaged with the T-shaped groove 2-1 on the rubber connector, and the ball groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com