Field coal gas content testing device and method

A technology for gas content and on-site testing, applied in material resistance and other directions, can solve the problems of inaccurate measurement data, complex equipment, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in detail below in conjunction with accompanying drawing:

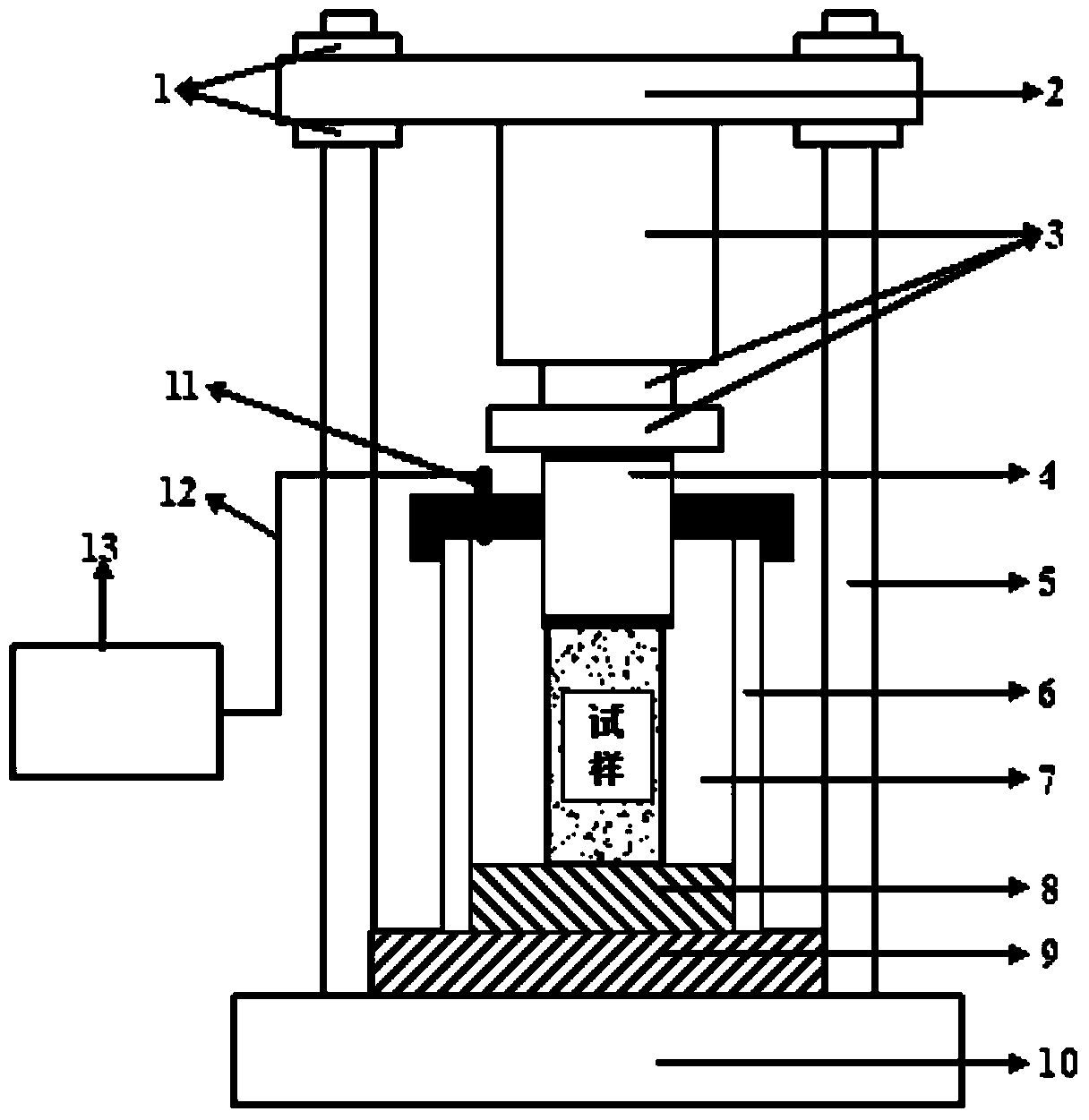

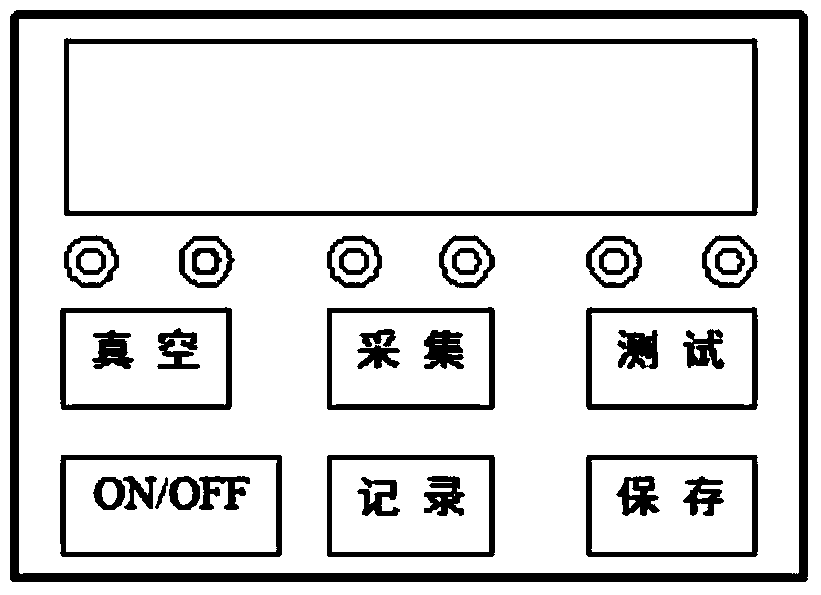

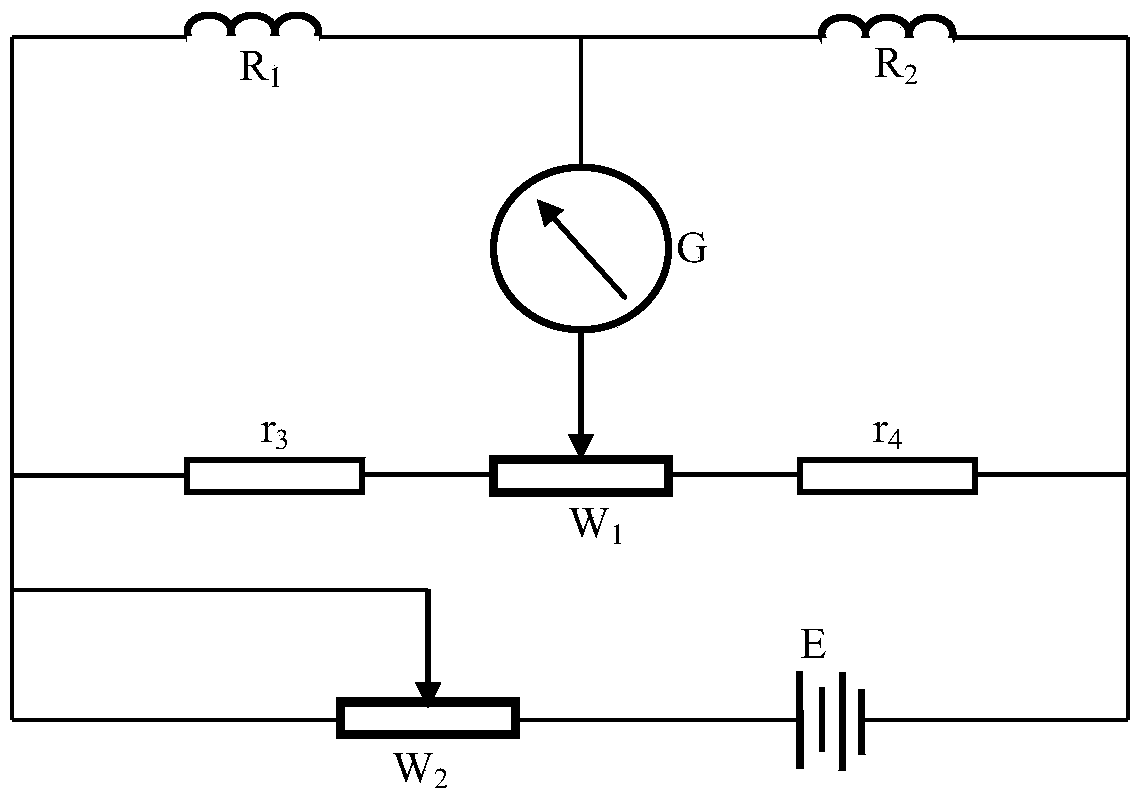

[0027] Such as Figure 1-2 As shown, an instrument for on-site testing of coal gas content includes an upper beam 2, a lower base 10, a support 5, a hydraulic jack system 3, a force transmission column 5, a sealed gas collection chamber 6, a sample base 8, a sealed set Air chamber base 9, gas discharge control valve 11, connecting pipeline 12, gas collection and testing device 13; the upper beam 2 of the test instrument is connected to the lower base 10 through the bracket 5, the hydraulic jack system 3 is connected to the upper beam 2, and the hydraulic jack system 3 The lower end of the hydraulic jack is connected to the force transmission column 4, and the lower end of the force transmission column 4 is in contact with the coal sample, which enables the hydraulic jack system 3 to pressurize the sample to cause it to rupture, ensuring the quality of gas collection. The samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com