Device and method for repairing disconnection of liquid crystal panel

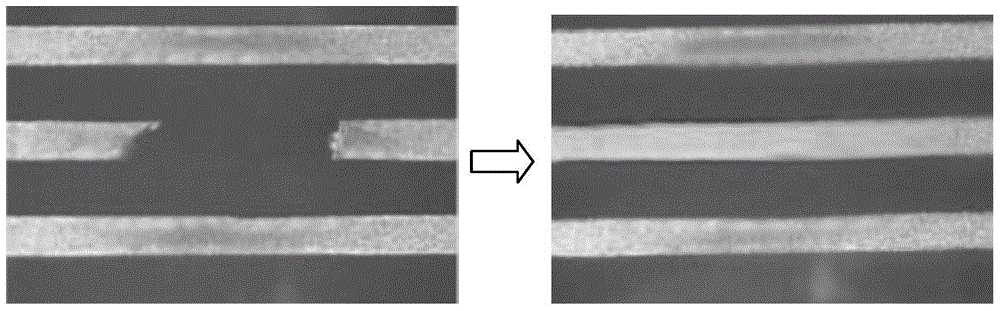

A liquid crystal panel and disconnection technology, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of long time consumption, limitation of TFT-LCD panel production capacity of TFT-LCD machines, and slow repair speed of disconnection repair devices And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

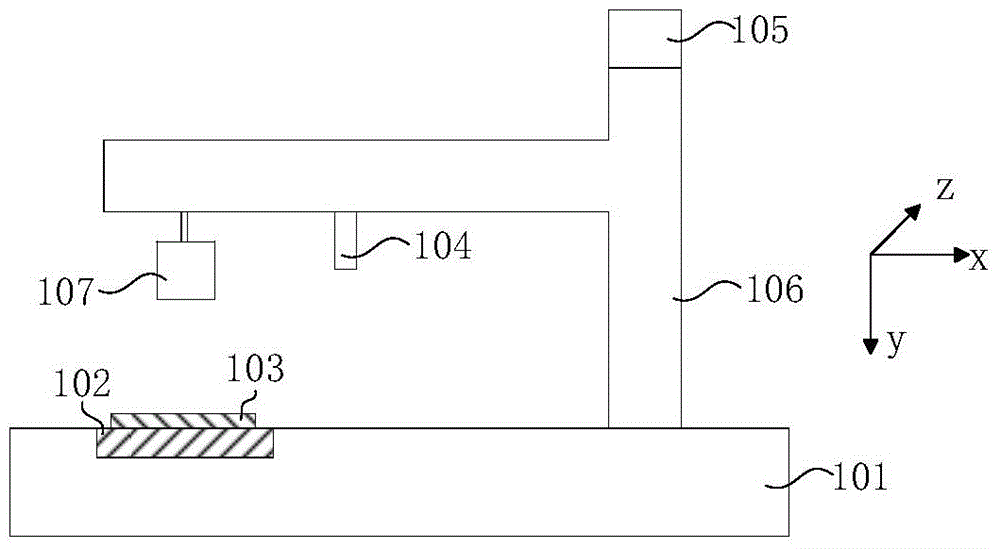

[0044] Hereinafter, the implementation of the present invention will be described in detail with reference to the accompanying drawings and embodiments, so as to fully understand how the present invention applies technical means to solve technical problems and achieve the realization process of technical effects and implement them accordingly. It should be noted that, as long as there is no conflict, each embodiment of the present invention and each feature in each embodiment can be combined with each other, and the technical solutions formed are all within the protection scope of the present invention.

[0045] In addition, the steps shown in the flowcharts of the drawings can be executed in a computer system such as a set of computer-executable instructions, and although the logical sequence is shown in the flowcharts, in some cases, they can be different Perform the steps shown or described in the order here.

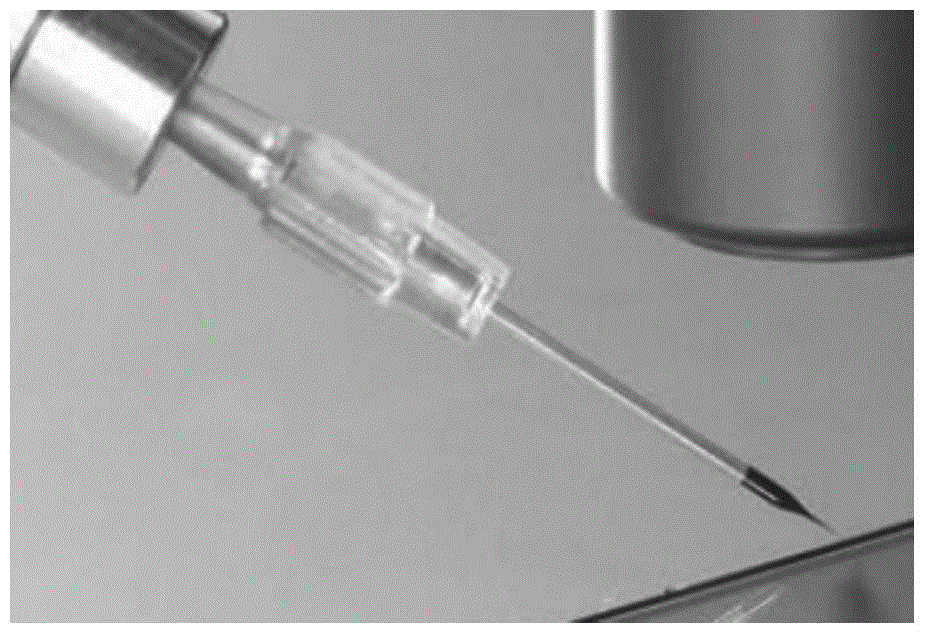

[0046] In order to improve the efficiency of repairing the broken wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com