Socket structure capable of preventing falling of plug

A plug and socket panel technology, applied in electrical components, coupling devices, circuits, etc., can solve the problems of relatively high structural size requirements of plugs, inconvenient use, and unsightly appearance, and achieve easy large-scale promotion, reliable structure, and equipment. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

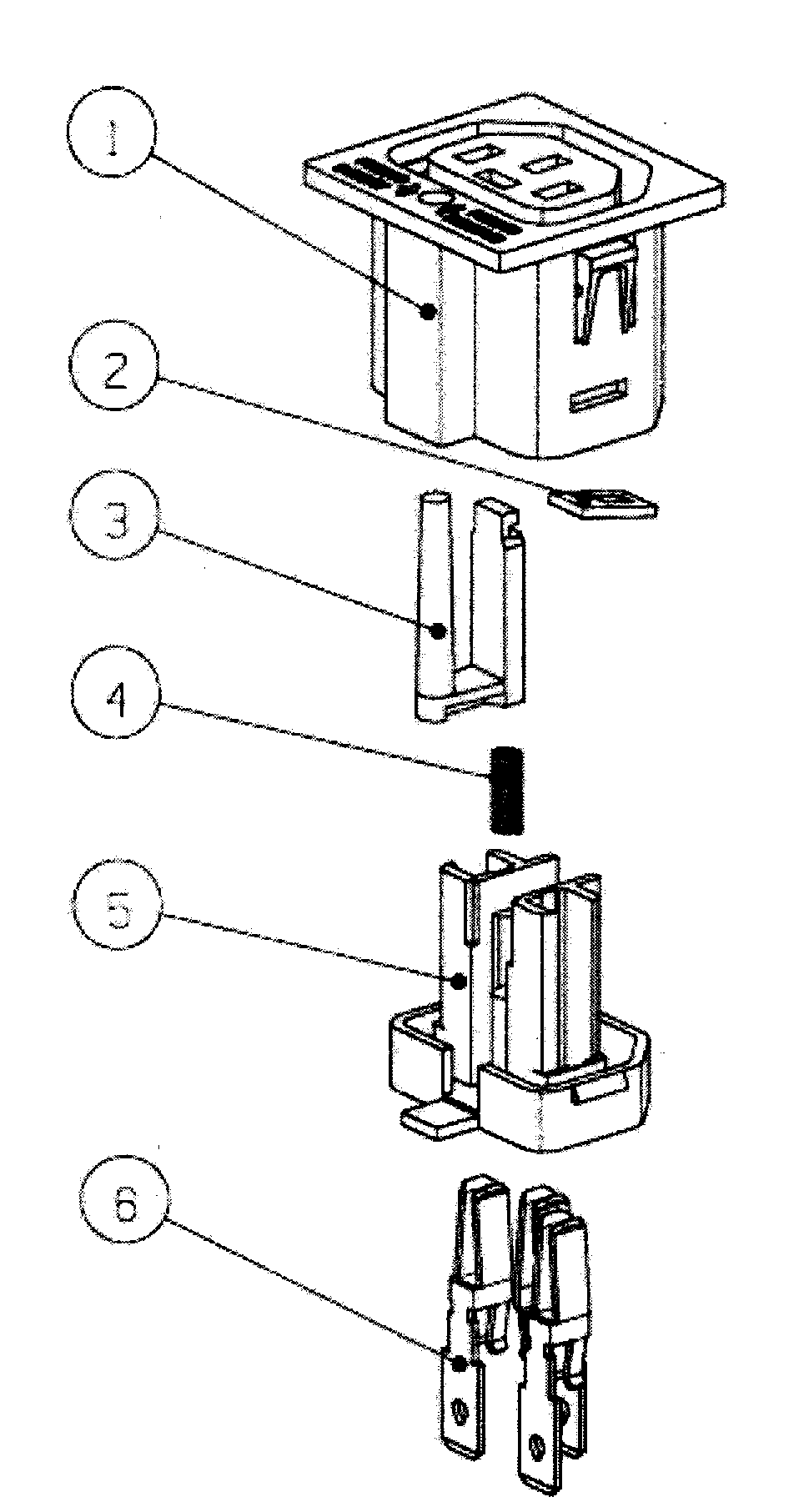

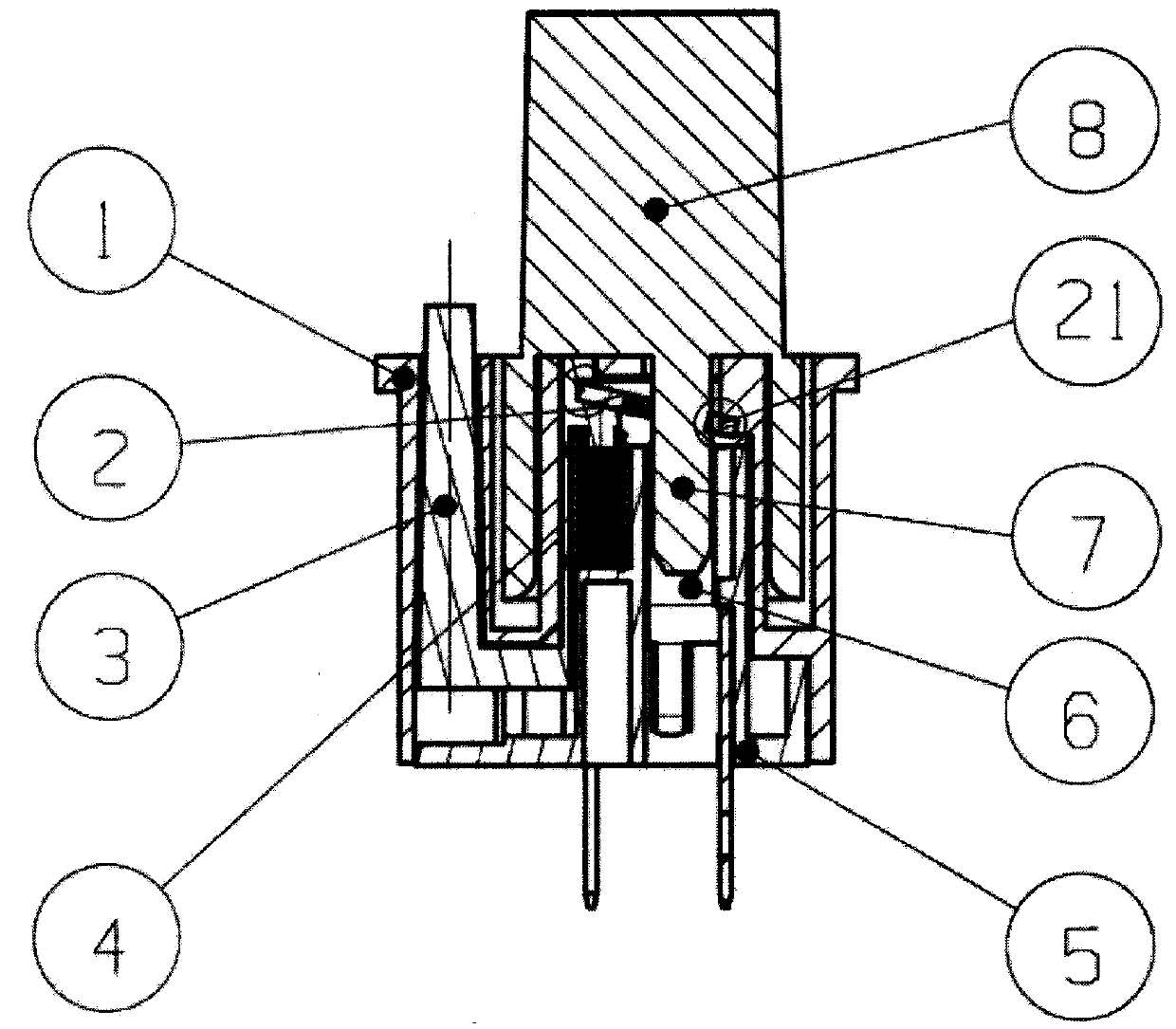

[0020] like figure 1 Shown is a socket structure that prevents the plug from falling off, including a socket panel (1), a block (2), a button (3), a spring (4), a rear seat (5) and a socket (6), and the rear seat (5) is an inverted "T" structure, and there are installation holes and installation protrusions on the rear seat (5); the socket (6) is fixed on the rear seat (5) through the installation holes on the rear seat (5) ; The spring (4) is fixed on the rear seat (5) through the installation protrusion on the rear seat (5); the button (3) is fixed on the rear seat (5) and connected to the spring (4); One end of the block (2) is connected to the button (3), and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com