Metal-containing polymeric reinforced pipe, method for manufacturing same and pipeline produced using said pipe

A polymer pipe, polymer technology, applied in the direction of pipes/pipe joints/fittings, manufacturing tools, metal processing equipment, etc., can solve problems such as high labor intensity, improve productivity and service life, increase productivity, improve strength and The effect of machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

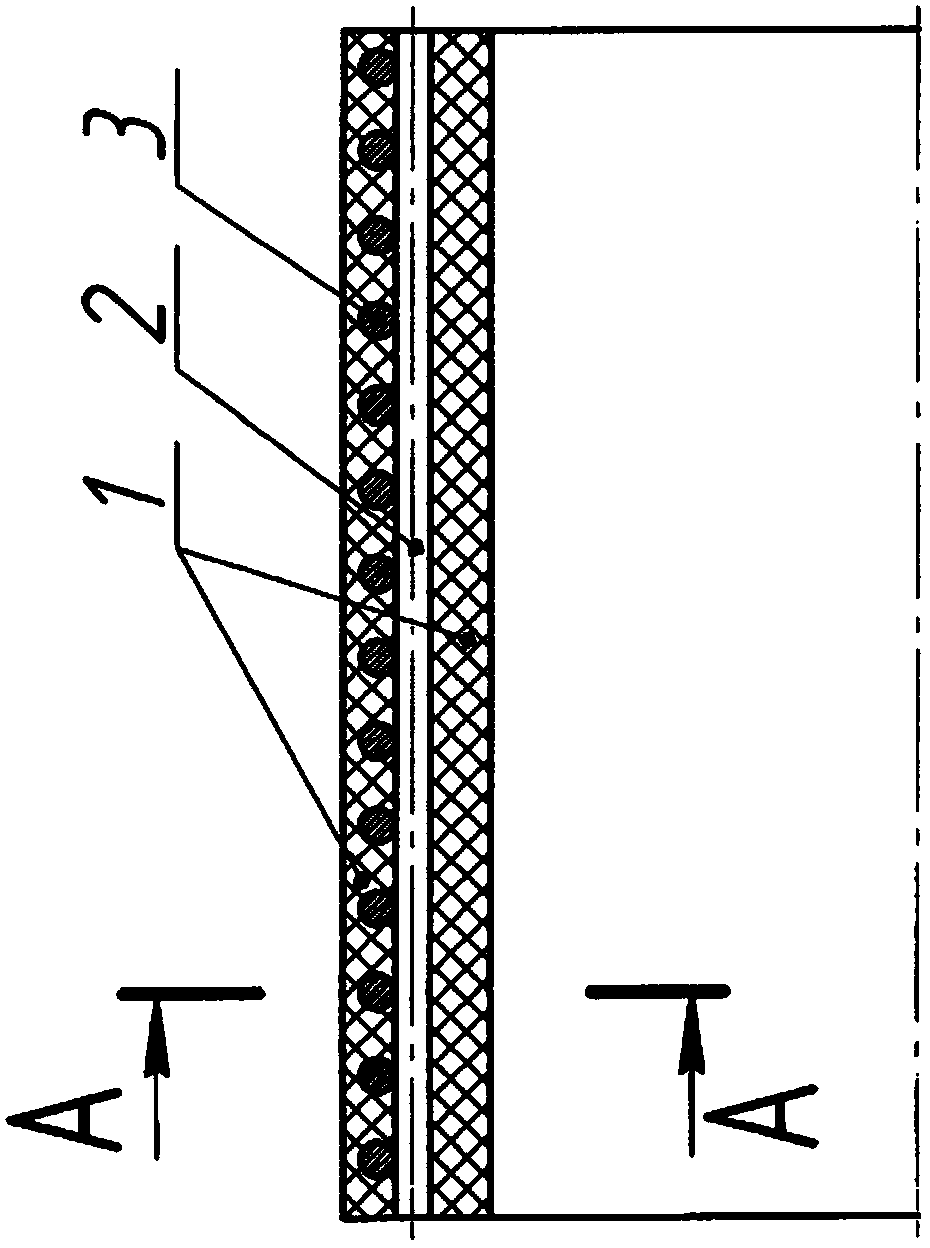

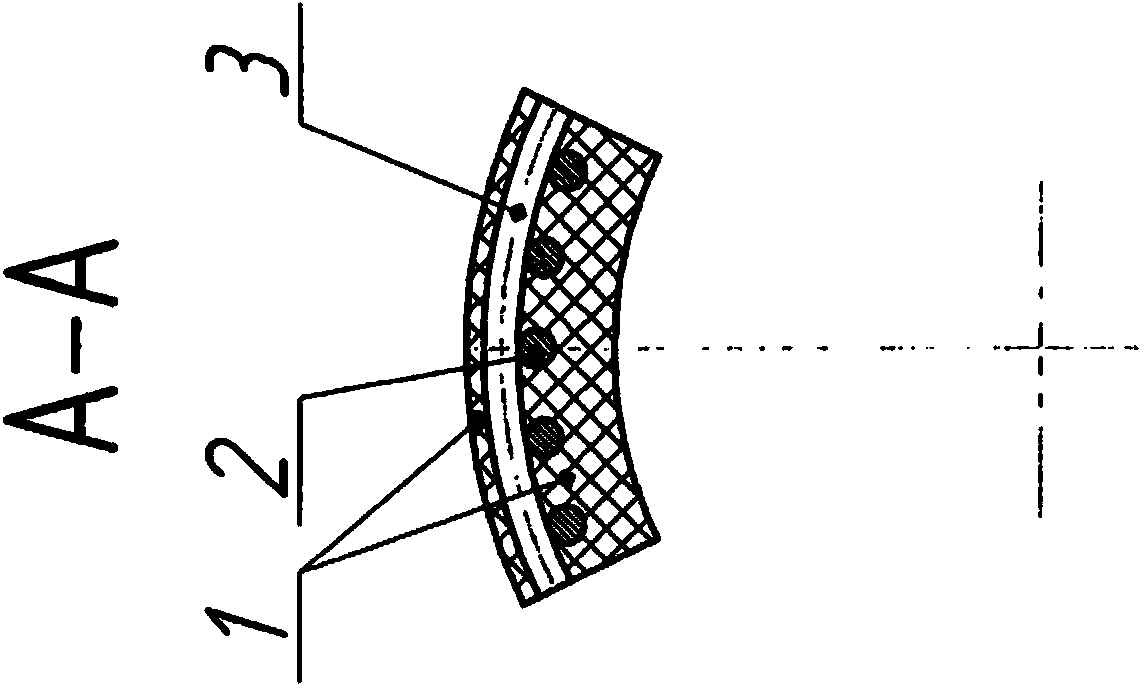

[0110] Metal-polymer reinforced pipes, such as figure 1 Shown is a polymer matrix 1 and a welded metal frame made of longitudinal 2 and transverse 3 reinforcing elements. The frame is produced by helically winding transverse stiffening elements 3 onto longitudinal stiffening elements 2 and they are welded to each other at each of their intersections. The metal-polymer reinforced tube is produced by extrusion, in which the welded reinforced frame is fed into the mold cavity, and the polymer melt is fed into the cavity at the same time, when the molded tube After leaving the mold cavity, it is subjected to intensive cooling on both sides, in which coolant is supplied to the inside and outside.

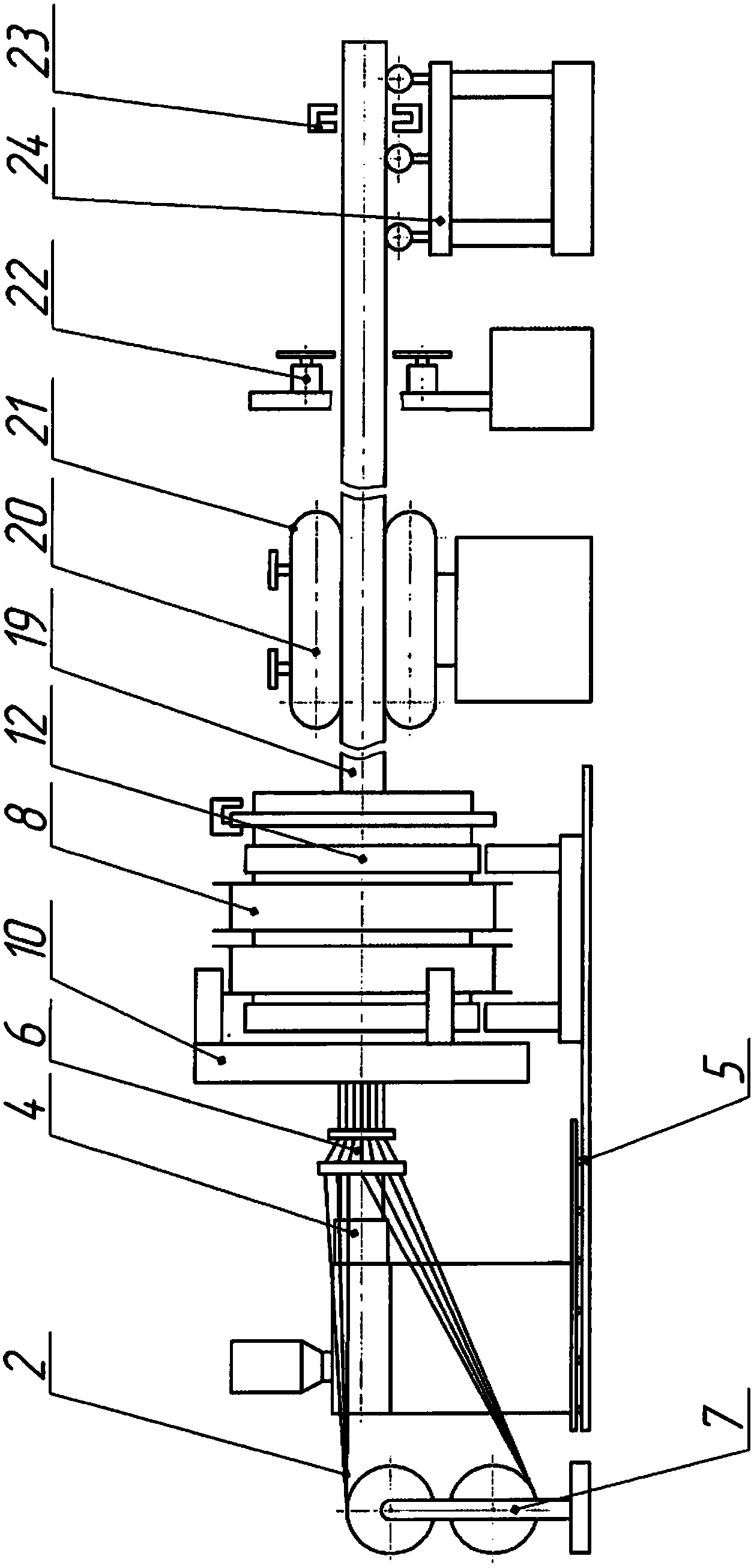

[0111] Plants for the continuous production of metal-polymer pipes, such as figure 2 and 3 As shown, there is an extruder 4 mounted on a base 5 and having an extrusion head 6 . Reels 7 and 8 are used to feed longitudinal and transverse metal reinforcement elements (in particular wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap