Wild honey separation machine

A technology of wild honey and separator, which is applied in honey collection, beekeeping, application, etc. It can solve the problems of low efficiency and lower honey quality, and achieve the effect of high work efficiency, complete separation and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

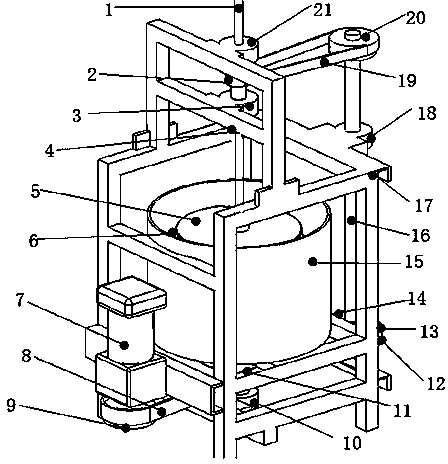

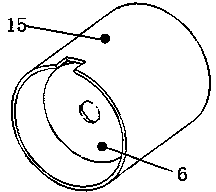

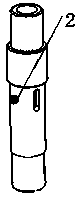

[0026] Such as Figure 1-6 As shown, frame 17 is welded with materials such as channel steel or angle steel, and outer barrel 15, centrifugal barrel 6 and pressure plate 5 are all made of stainless steel; Made of steel. For the convenience of description, the platen shaft and the pulley on the shaft are considered as one. The screw mandrel is a threaded straight rod, which has a screw mandrel stroke groove 22 on the bar, and the lower end is welded or bolted to the pressure plate and fixed. The platen shaft is a tubular hollow shaft, and the inner wall has an internal thread that cooperates with the screw mandrel, and the platen shaft is installed on the frame by the upper bearing seat 21 of the platen shaft and the lower bearing seat 3 of the platen shaft. When the platen shaft rotates relative to the screw, the screw moves up or down. In order to ensure that the screw does not rotate automatically, a limit bar is installed on the two bearing seats of the pressure plate sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com