Glass gas-liquid separator

A gas-liquid separator and glass technology, which is applied in laboratory utensils, laboratory containers, chemical instruments and methods, etc. The effect of good separation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

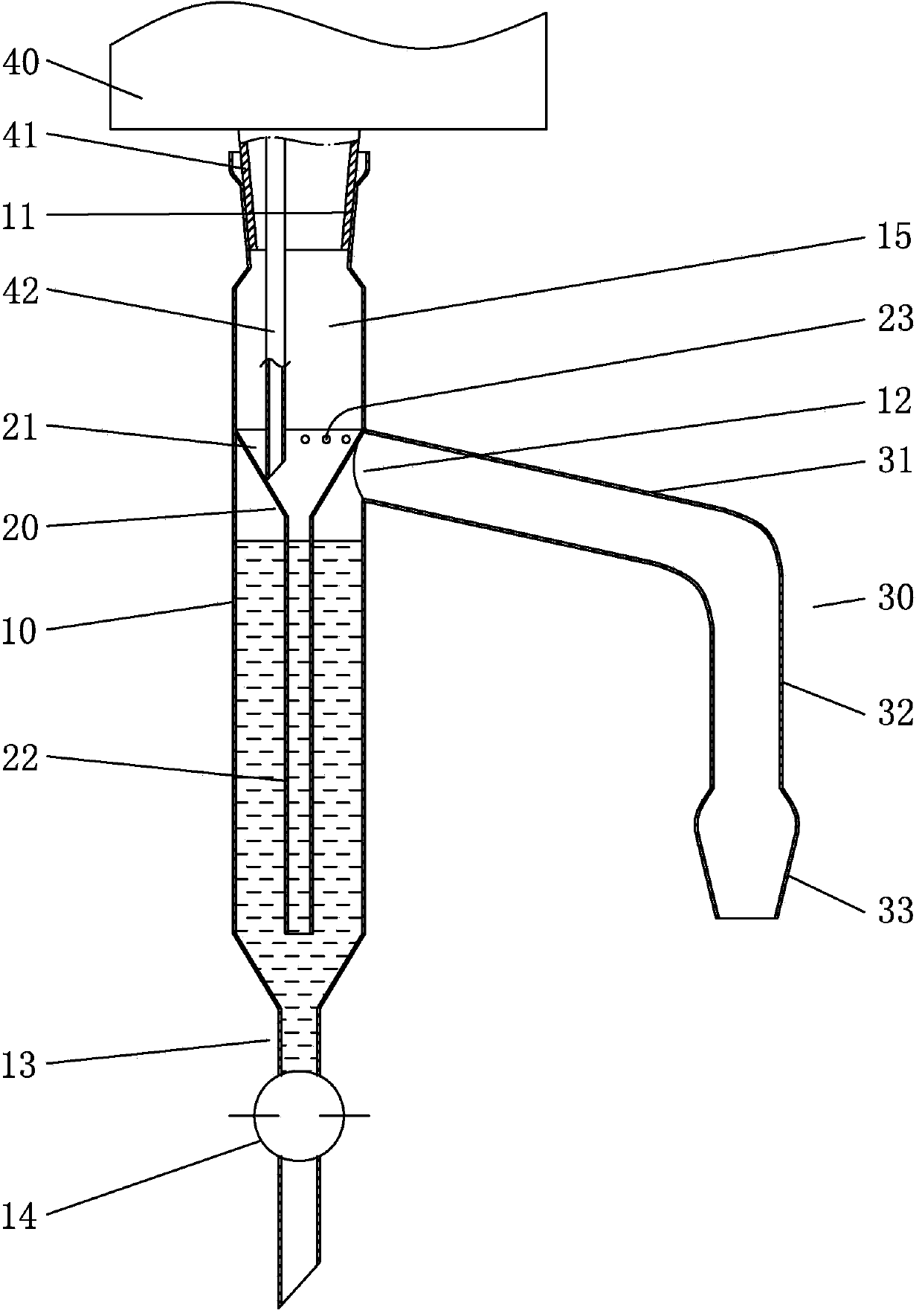

[0018] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 :

[0019] Gas-liquid separator made of glass, the upper side of the tube body 10 is provided with an inner frosted interface 11, the lower side of the tube body 10 is provided with a constricted part 13, and a valve 14 is arranged on the constricted part 13, and the middle and upper part of the inner cavity of the tube 15 An infusion funnel 20 with a large top and a small bottom is provided, and the upper end periphery of the infusion funnel 20 is connected with the inner wall of the tube body 10, and an opening 12 is arranged on the inner wall of the tube body 10 at the lower side of the junction of the infusion funnel 20 and the tube body 10, and the opening 12 is connected with a branch pipe 30 communicating with the inner cavity 15 of the tube, and the outer end of the branch pipe 30 is provided with an external frosted interface 33...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com