Eccentric 360-degree magnetic system non-belt automatic ore discharge permanent magnet drum type magnetic separator

A permanent magnet cylinder type, beltless technology, applied in the field of mining equipment, can solve the problems of small unloading volume, wear of the sorting cylinder and belt, and inability to unload, etc., to achieve the effect of efficient separation and lower production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

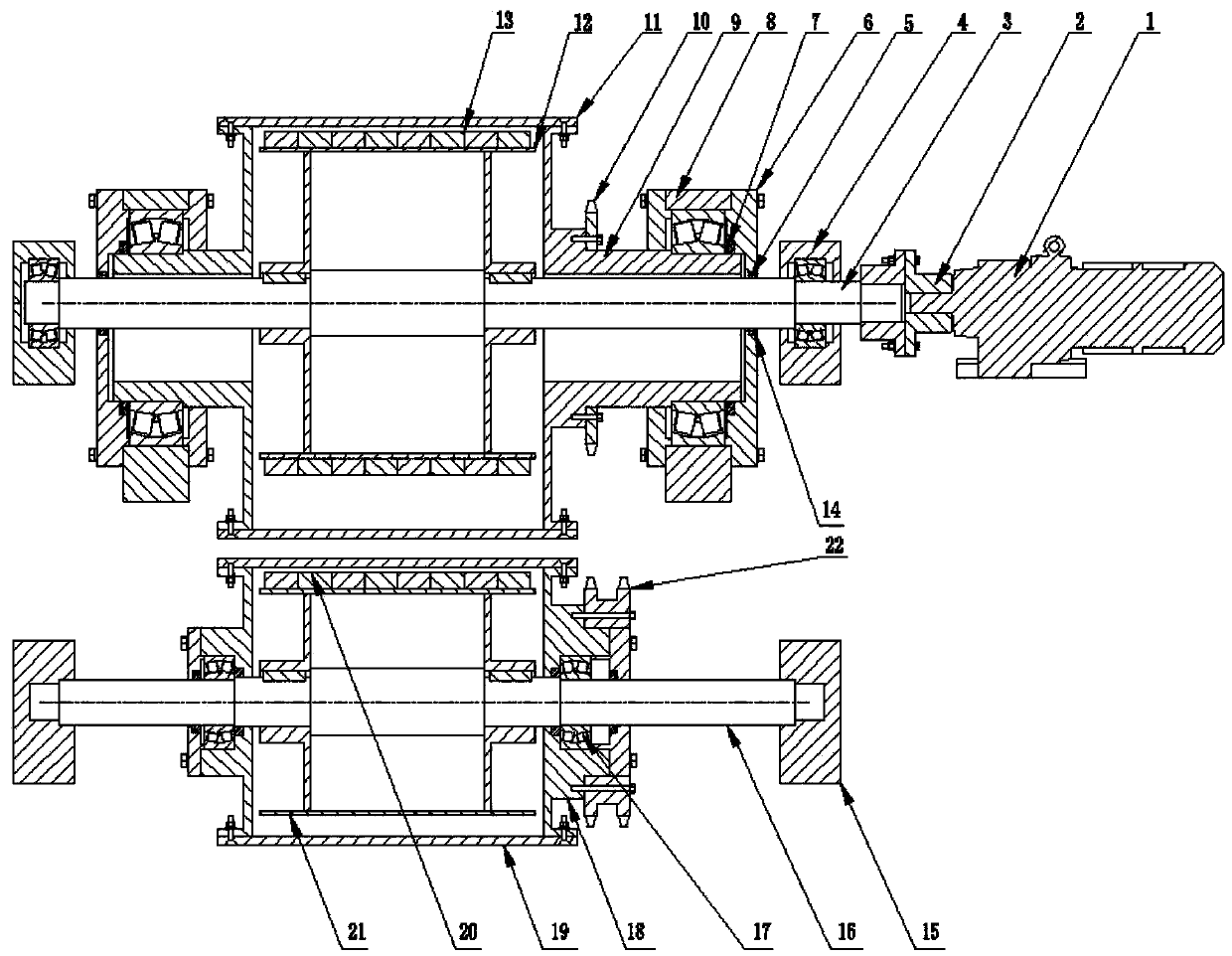

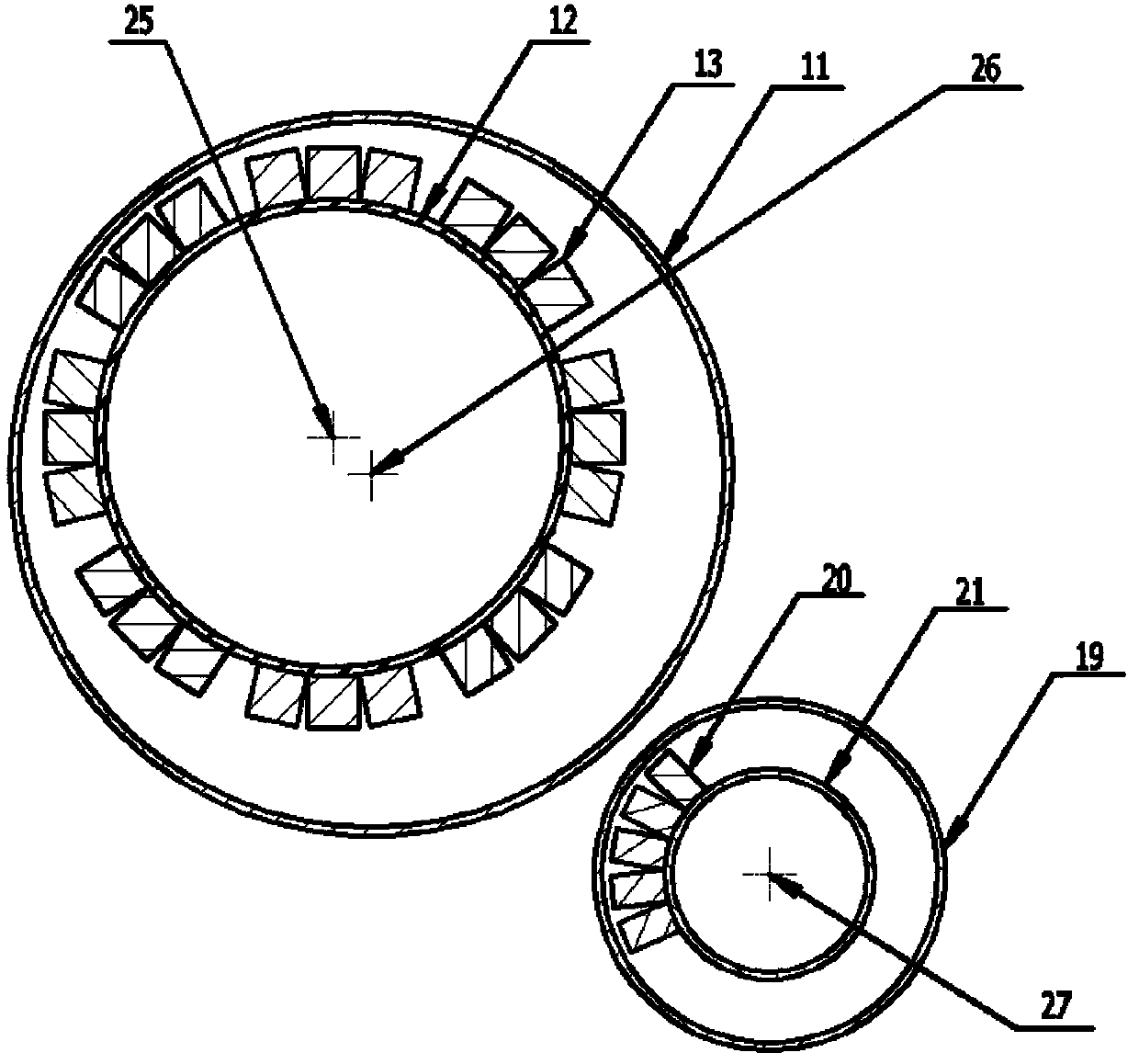

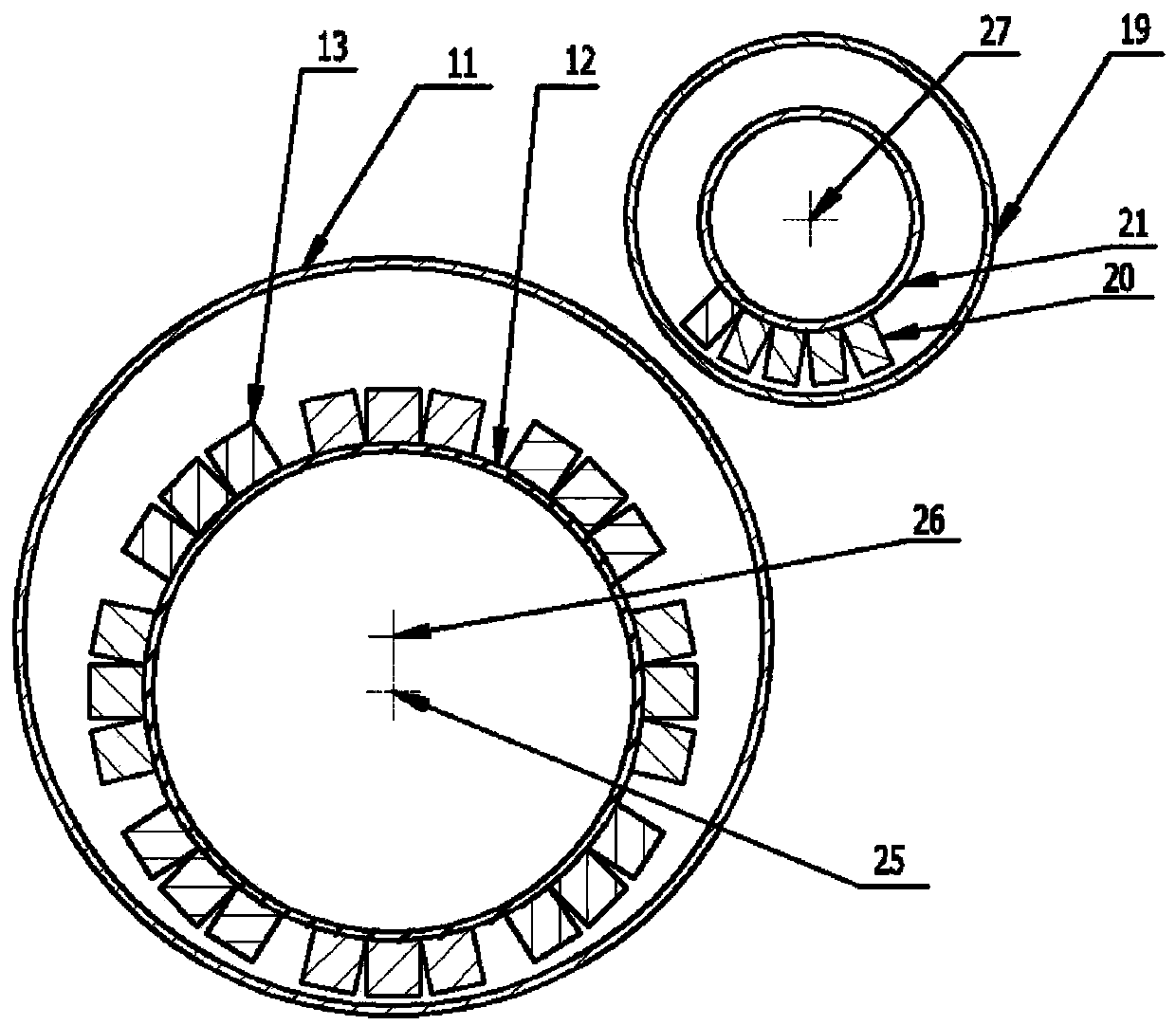

[0027] Such as figure 1As shown, the present invention includes a deceleration motor 1, the output end of the deceleration motor 1 is connected to one end of the central axis 3 of the inner cylinder through a coupling 2, and an inner cylinder 12 is arranged outside the central axis 3 of the inner cylinder, so The outer circumference of the inner cylinder 12 is provided with a magnetic system 13 with a magnetic envelope angle of 360 degrees. The 360-degree magnetic system 13 is covered with a separation cylinder 11, and the two ends of the separation cylinder 11 are respectively connected to the separation cylinder. The hollow shaft 9 of the selection cylinder is fixedly connected, and the hollow shafts of the separa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com