Self-discharge screening method of lithium ion batteries

A technology of a lithium ion battery and a screening method, which is applied in the field of self-discharge screening of lithium ion batteries, can solve the problems of no memory effect, complexity, and high misjudgment rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Taking the screening of a batch of fully charged batteries as an example: select a batch of lithium-ion batteries, and describe the self-discharge screening method of lithium-ion batteries in detail.

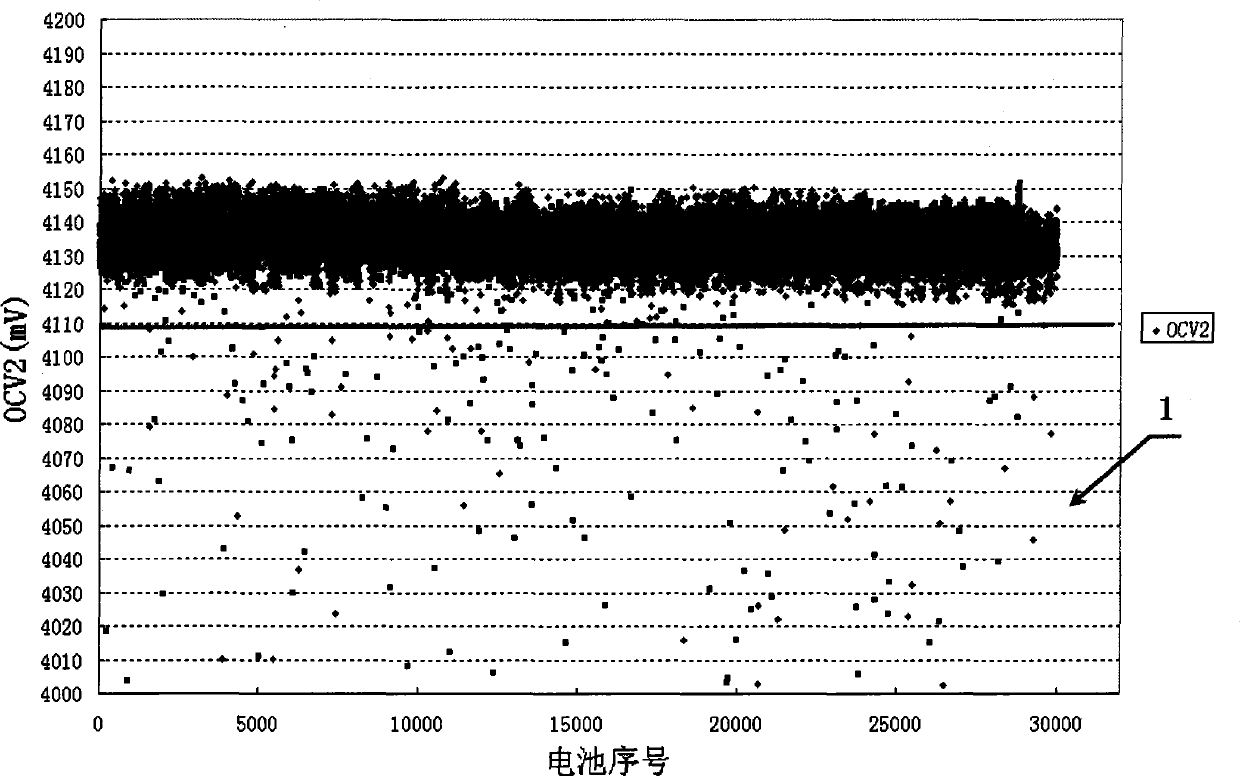

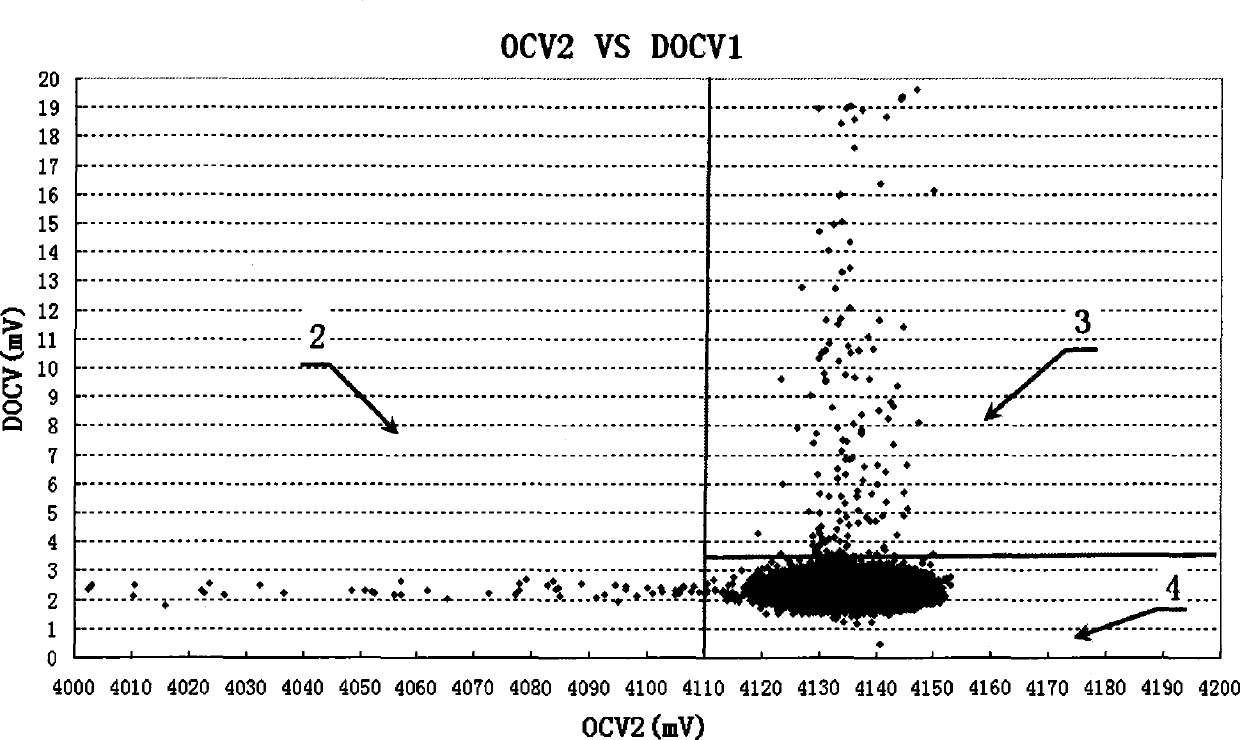

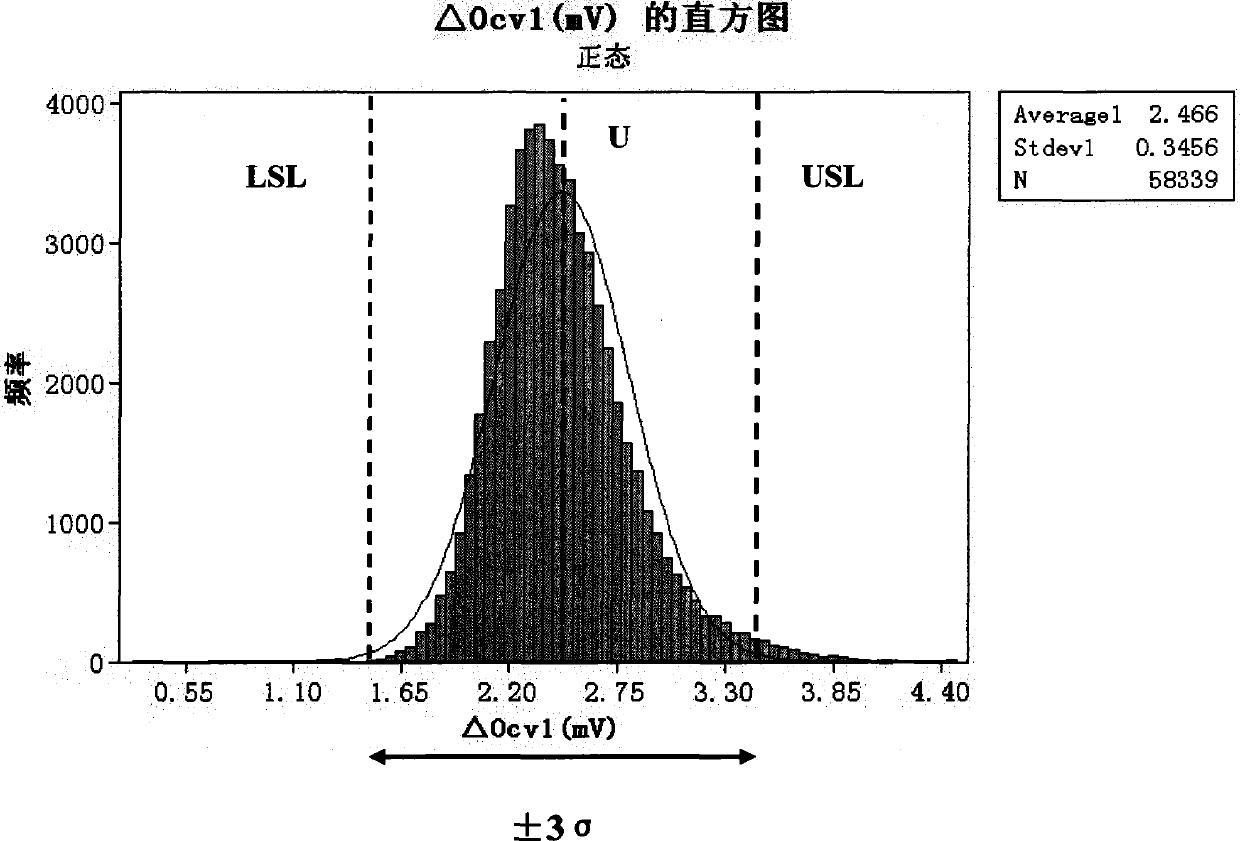

[0014] figure 1 Zone 1 in and figure 2 Screening of self-discharging batteries in Zone 2: Precharge a batch of lithium-ion batteries to 4.2V with 0.2C, and after aging for 3 days at a high temperature of 45±3℃, store them at room temperature for the first time for 1 day, and measure the open circuit voltage, which is recorded as OCV1, the second storage at room temperature for 10 days, detect the open circuit voltage, and record it as OCV2; analyze the voltage change after the second storage at room temperature, and determine the critical value U0 of the voltage change in the same period, figure 1 The voltage of the battery with OCV2 < 4110mV drops faster, and this part is excluded as a serious self-discharge battery.

[0015] figure 2 Screening of self-discharging b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com