Check and calibration mold for reamer blades

A blade and reamer technology, applied in the field of inspection and correction molds for reamer blades, can solve problems such as non-normal production, difficult detection of helical blade errors, and reamer efficiency problems, so as to save costs, improve quality, and avoid accumulated errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

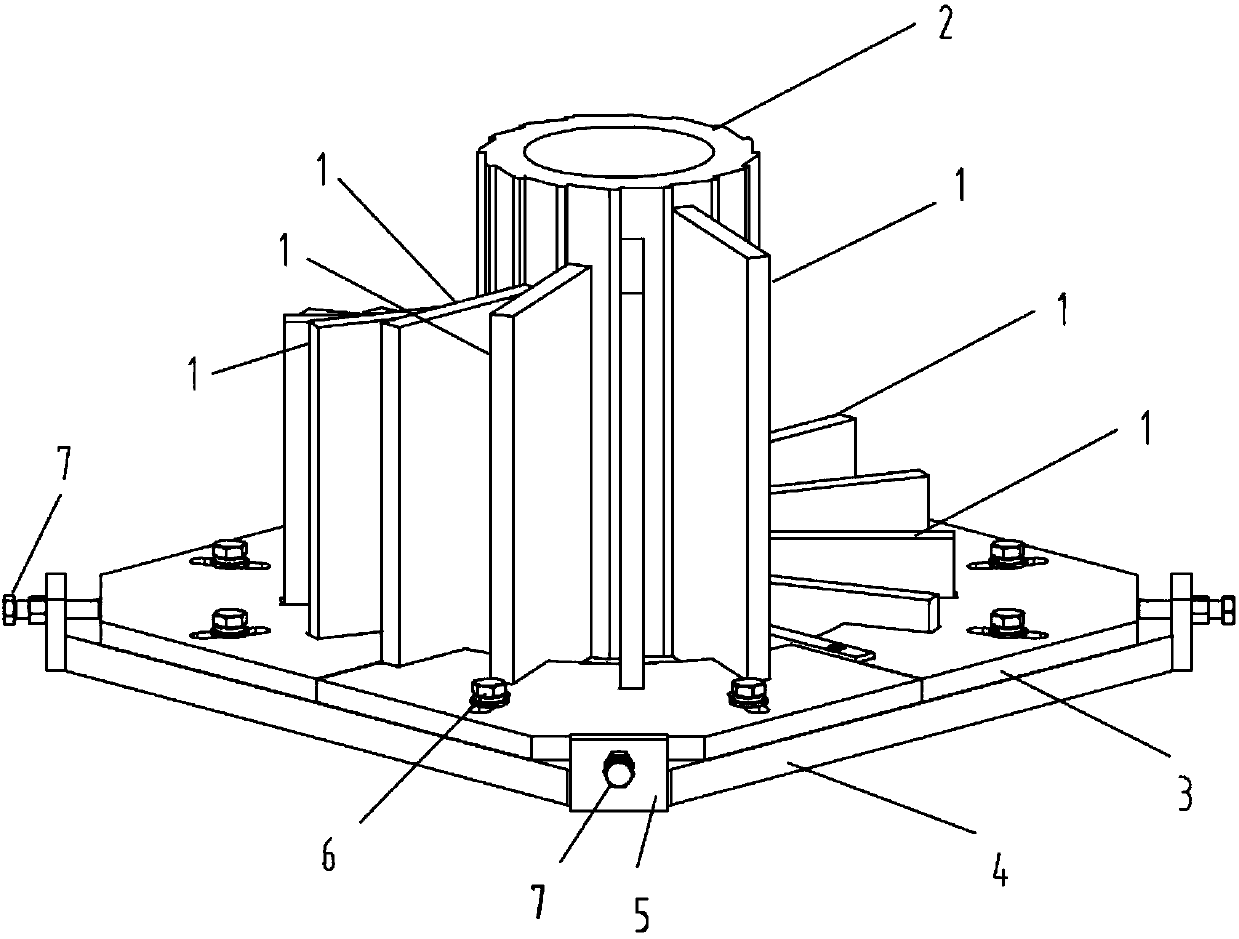

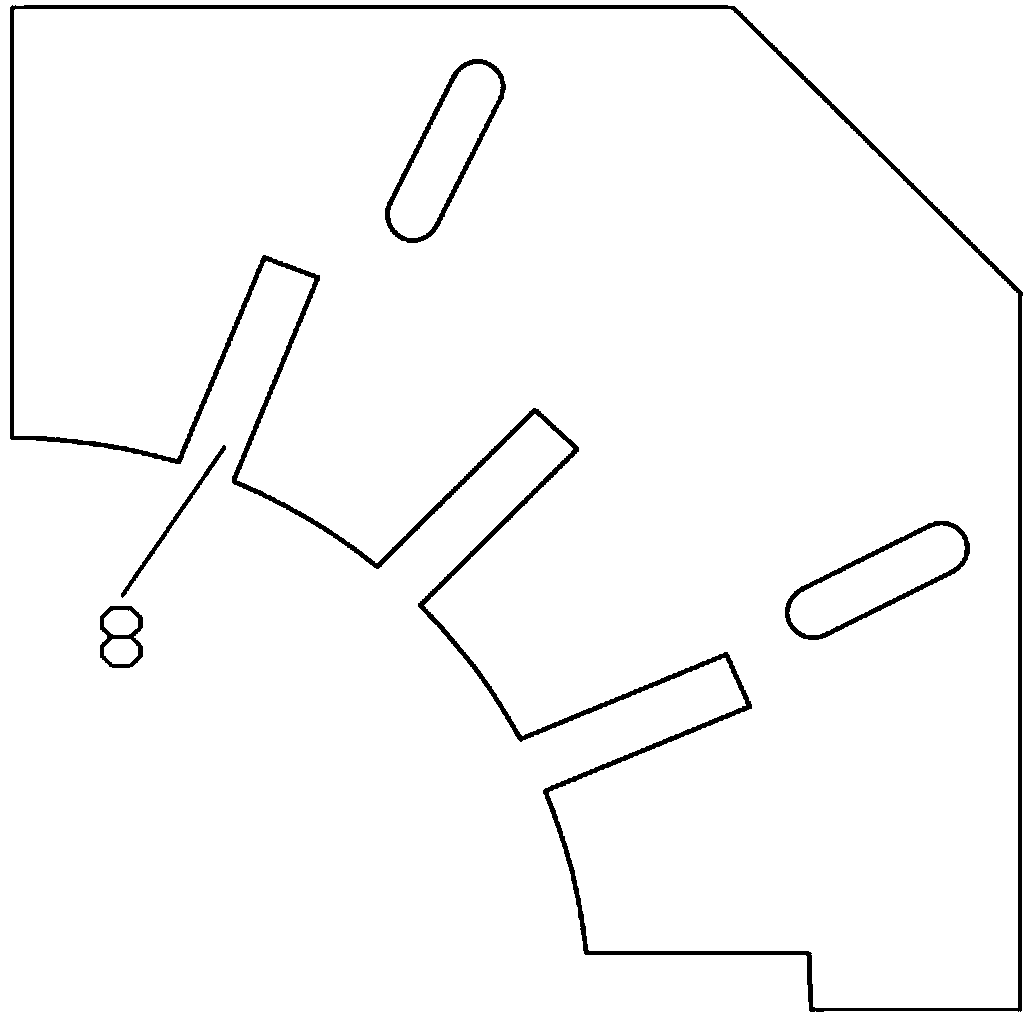

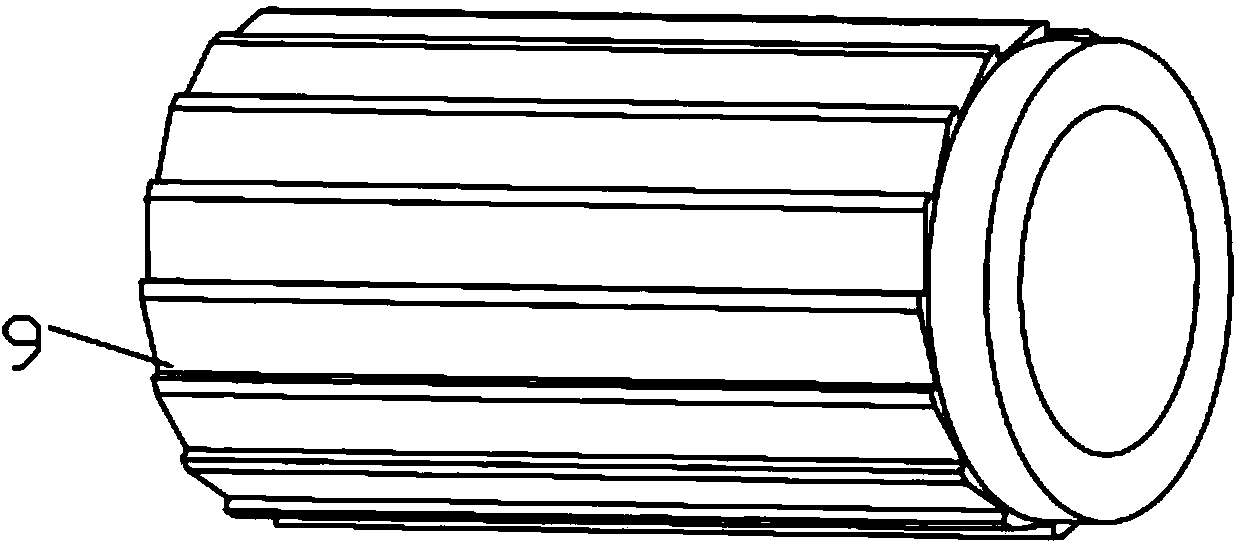

[0018] Such as figure 1 and 2 As shown, the inspection and correction mold of the reamer blade of the present invention, the reamer blade is a helical blade lower than 1 pitch H, and the mold includes a positioning step for placing the reamer blade and a mandrel for fixing the positioning step 2. The positioning plate 3 and the base 4; the positioning step is composed of N correction blocks 1 uniformly arranged on the circumference with a width consistent with the width of the reamer blade and whose height is successively increased by a multiple of H / N. The inner side of each correction block is aligned with the The mandrel is connected, and the outer bottom is inserted into N radial positioning slots 8 with equal spacing on several positioning plates. The positioning plates are arranged along the circumferential direction of the mandrel and connected with the base bolts 6 . There are 4 positioning plates in this embodiment. The base is square, and the four corners of the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com