Coil packaging machine

A packaging machine and coil technology, applied in the direction of coiling strips, transportation and packaging, thin material processing, etc., can solve the problems of poor curling effect, loose curling, uneven unilateral, etc., and achieve good curling effect and tight curling. Strong, avoid unilateral uneven effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

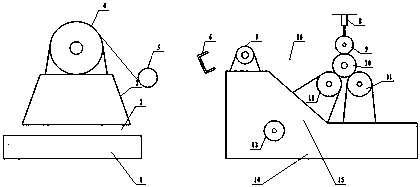

[0017] The coil packaging machine of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments of the present invention.

[0018] From figure 1 It can be seen from the figure that the coil packaging machine includes a guide device and a curling device. The guide device includes a sliding base 1 and a guide roller 4. A guide bracket 3 is arranged below the guide roller 4. The guide bracket 3 passes through The sliding wheel 2 is movably connected with the sliding base; the transition roller a5 and the computer deviation correction device 6 are arranged between the unwinding device and the curling device; the computer deviation correction device 6 includes a sensor and an actuator, and the sensor is arranged above the coil between the unwinding device and the curling device , used to detect the position of the coil and transmit the data to the control system. The actuator is connected with the opening device fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com