Position-adjustable elevator vertical expansion device with avoiding space

A technology for avoiding space and tensioning devices, which is applied in transportation, packaging, elevators, etc., can solve the problems of large space occupied by tensioning devices, increase the cost of elevator use, and limit the use of elevators, so as to improve installation efficiency, occupy small space, and The effect of low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

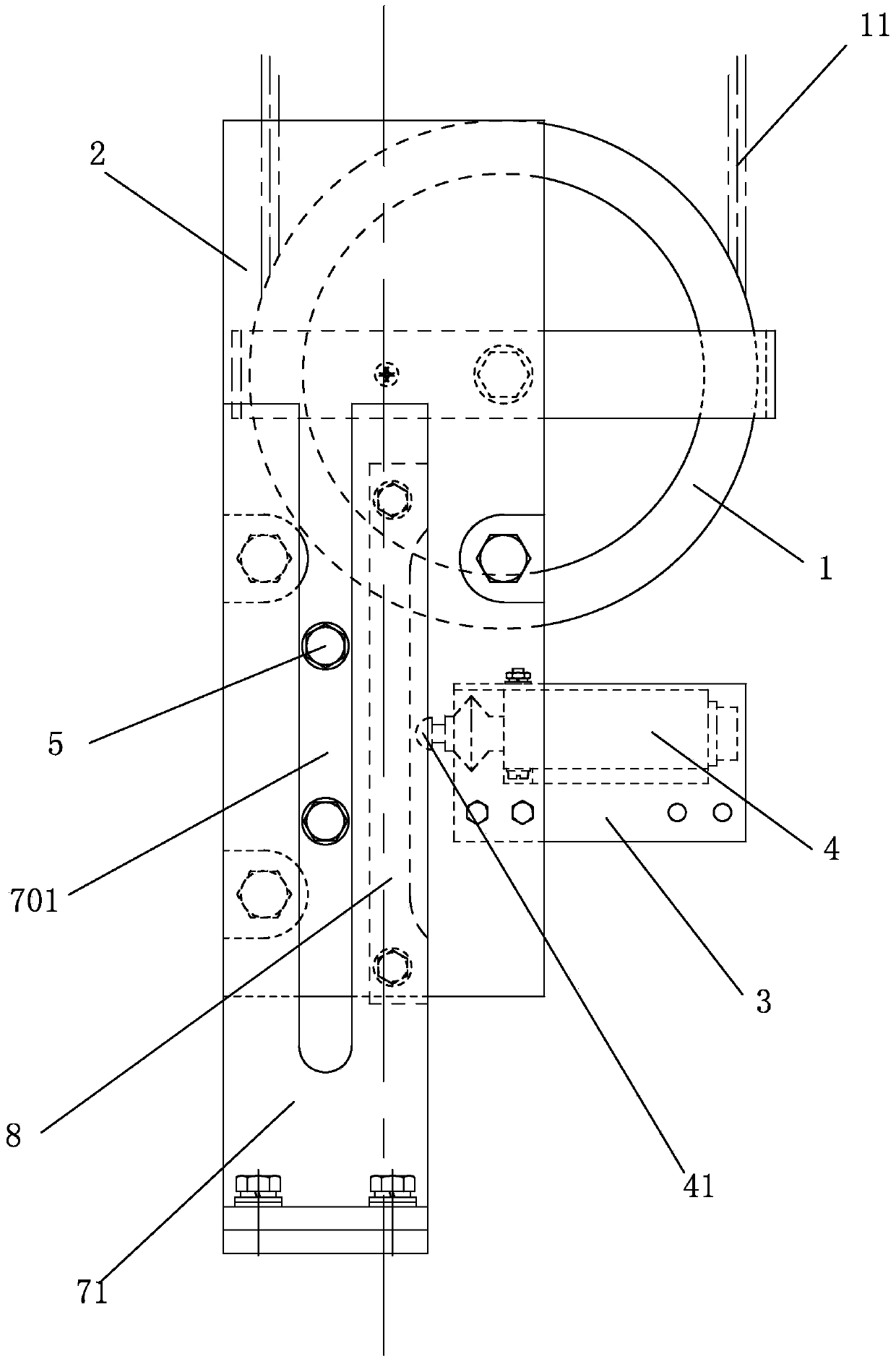

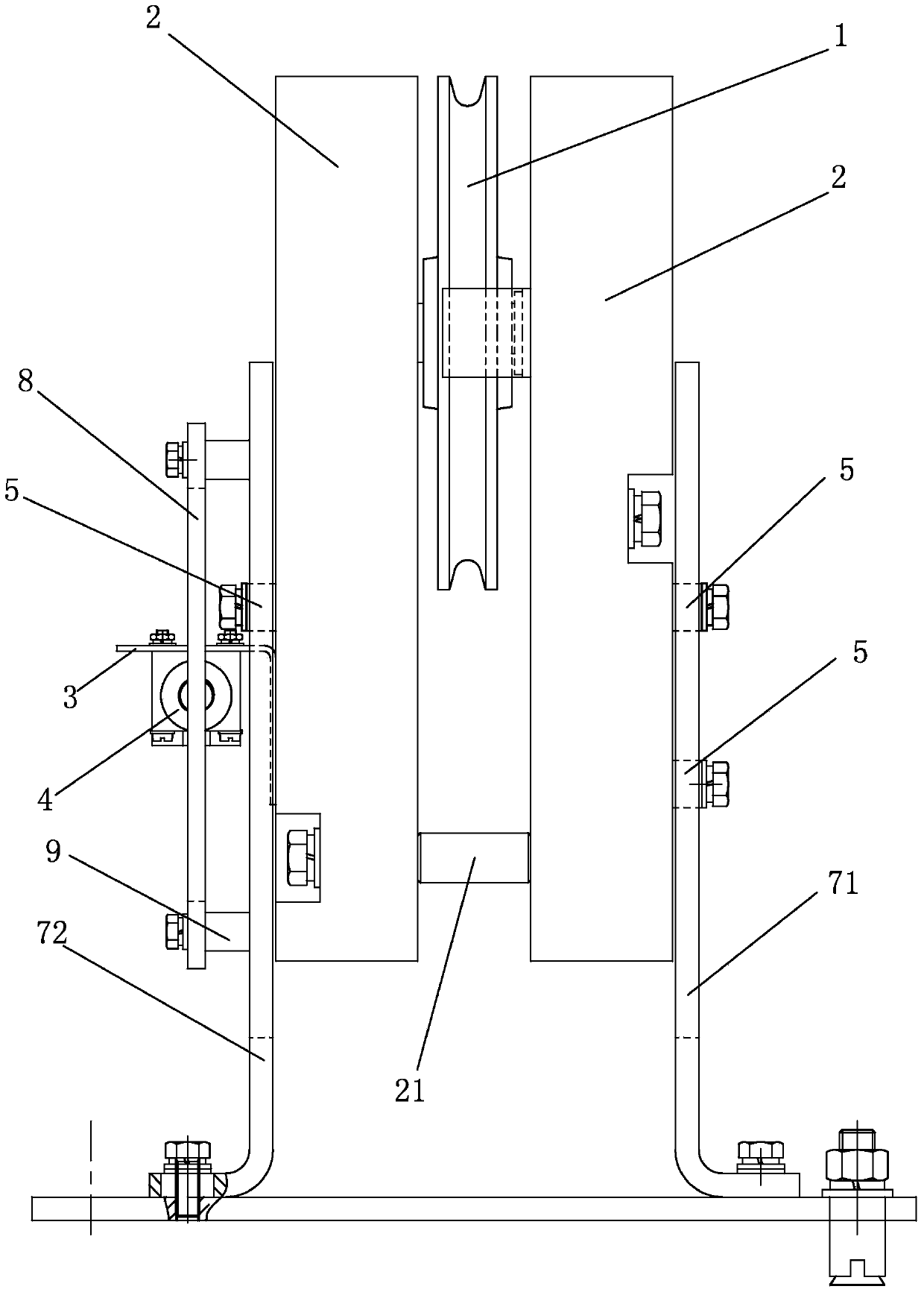

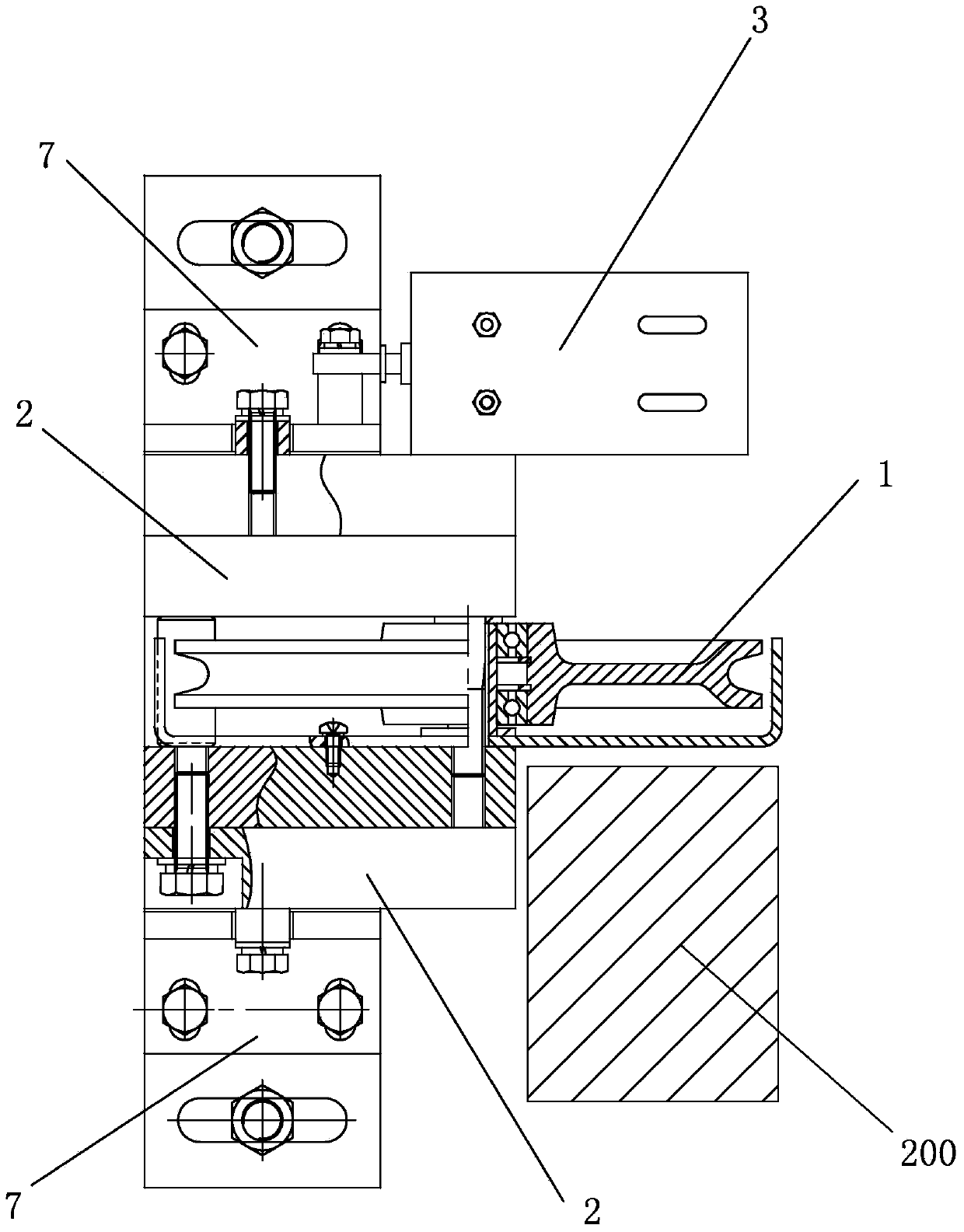

[0022] Such as figure 1 As shown, the elevator vertical tensioning device with adjustable position and avoidance space of the present invention includes a weight part, a bracket part, and a combination Figure 4 , Figure 5 As shown, the weight part includes two weights 2 symmetrically arranged front and back, a sheave 1 is installed between the two weights 2, a steel wire rope 11 is wound on the sheave 1, the sheave of the sheave 1 and the weight 2 Arranged in parallel front and back, the middle of the two weights 2 is provided with a threaded hole, the threaded shaft 6 passes through the threaded hole and the center of the rope wheel 1 from back to front, and the rope wheel 1 is installed between the two weights 2, and the two The bottom ends of each weight 2 are fixedly connected together. recombine figure 2 As shown, the bottom ends of the two weights 2 can be fixed by bolts and spacer connecting columns 21 between the weights, so that there is a space between the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com