Dishwashing liquid special for tableware

A dishwashing liquid and tableware technology, applied in the field of detergents, can solve the problems of insufficient decontamination ability, achieve the effect of removing oil stains, not polluting the environment, and not irritating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

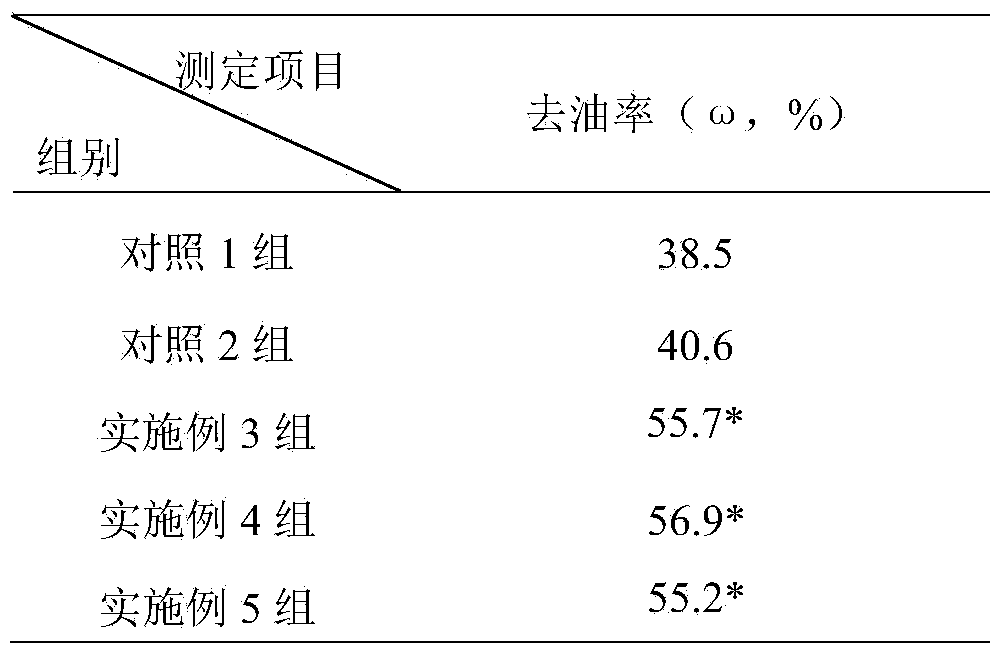

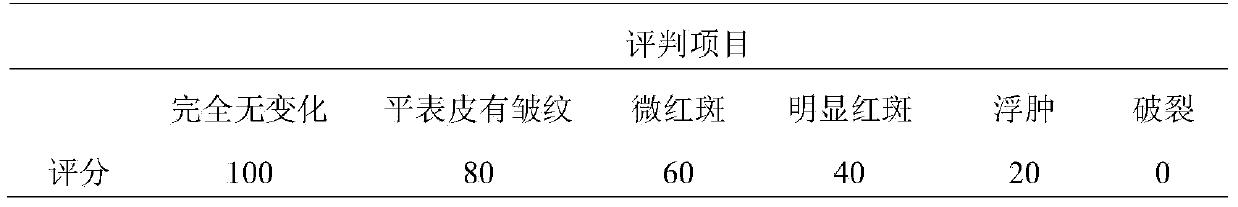

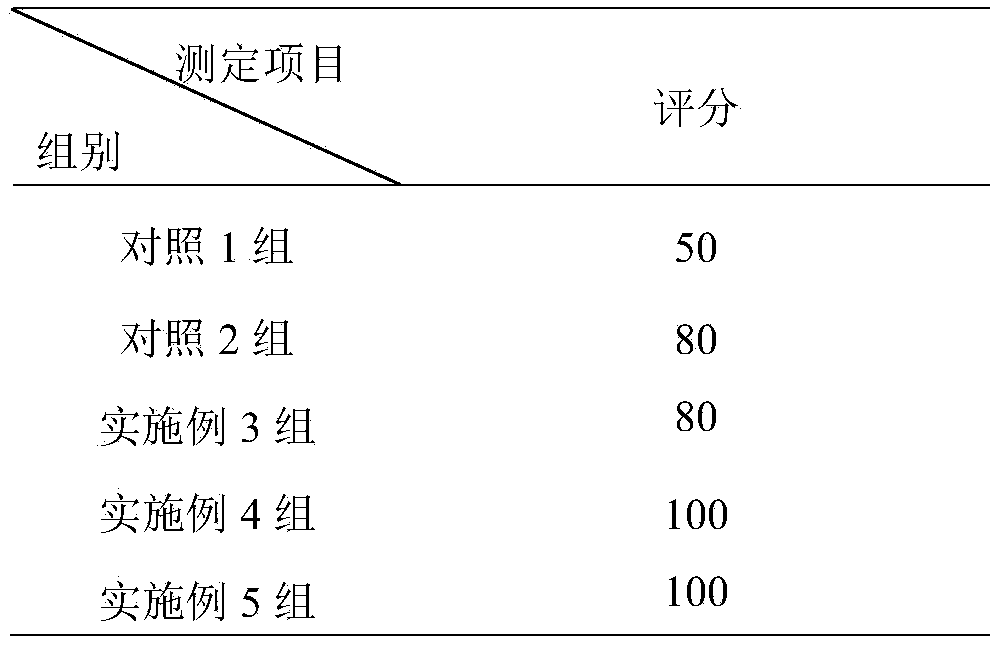

Examples

Embodiment 1

[0021] Party:

[0022] Ginger 50g, Aloe Vera 40g, Cocamidopropyl Betaine 8g, Sodium Chloride 0.4g, Disodium EDTA 1g, Propylene Glycol 10g, Wheat Protein 10g, Lemon Oil 0.02g, Sodium Dodecylbenzene Sulfonate 2g, sodium hypochlorite 0.1g, sodium bicarbonate 0.2g.

[0023] Preparation:

[0024] (1) Ginger and aloe are crushed and squeezed to extract the juice;

[0025] (2) Cocamidopropyl betaine, disodium edetate, sodium dodecylbenzenesulfonate and essence are added to propylene glycol, stirred to obtain propylene glycol liquid;

[0026] (3) Put wheat protein, sodium chloride and sodium hypochlorite in a certain amount of water, mix with the above-mentioned extracted juice and propylene glycol solution, disperse at a high speed of 4000r / min for 10 minutes, finally add sodium bicarbonate, mix well, and obtain.

Embodiment 2

[0028] Party:

[0029] Ginger 50g, Aloe Vera 60g, Cocamidopropyl Betaine 16g, Sodium Chloride 0.8g, Disodium EDTA 5g, Propylene Glycol 16g, Wheat Protein 20g, Cinnamon Oil 0.06g, Sodium Dodecylbenzene Sulfonate 10g, sodium hypochlorite 0.5g, sodium bicarbonate 0.8g.

[0030] Preparation:

[0031] (1) Ginger and aloe are crushed and squeezed to extract the juice;

[0032] (2) Cocamidopropyl betaine, disodium edetate, sodium dodecylbenzenesulfonate and essence are added to propylene glycol, stirred to obtain propylene glycol liquid;

[0033] (3) Put wheat protein, sodium chloride and sodium hypochlorite in a certain amount of water, mix with the above-mentioned extracted juice and propylene glycol solution, disperse at a high speed of 6000r / min for 20 minutes, finally add sodium bicarbonate, mix well, and obtain.

Embodiment 3

[0035] Party:

[0036] Ginger 50g, Aloe Vera 50g, Cocamidopropyl Betaine 12g, Sodium Chloride 0.6g, Disodium EDTA 3g, Propylene Glycol 13g, Wheat Protein 15g, Peppermint Oil 0.04g, Sodium Dodecyl Benzene Sulfonate 6g, sodium hypochlorite 0.3g, sodium bicarbonate 0.5g.

[0037] Preparation:

[0038] (1) Ginger and aloe are crushed and squeezed to extract the juice;

[0039] (2) Cocamidopropyl betaine, disodium edetate, sodium dodecylbenzenesulfonate and essence are added to propylene glycol, stirred to obtain propylene glycol liquid;

[0040] (3) Put wheat protein, sodium chloride and sodium hypochlorite in a certain amount of water, mix with the above-mentioned extracted juice and propylene glycol solution, disperse at a high speed of 5000r / min for 15 minutes, finally add sodium bicarbonate, mix well, and obtain.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap