Inductor used in quenching of large-scale forged steel supporting roll

A technology of inductors and support rolls, which is applied in the direction of quenching devices, furnace types, process efficiency improvement, etc., can solve problems such as poor anti-vibration ability, inability to measure temperature accurately in real time, inconvenient maintenance, etc., and achieve anti-inductive vibration Strong ability, convenient temperature measurement, and the effect of prolonging the heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

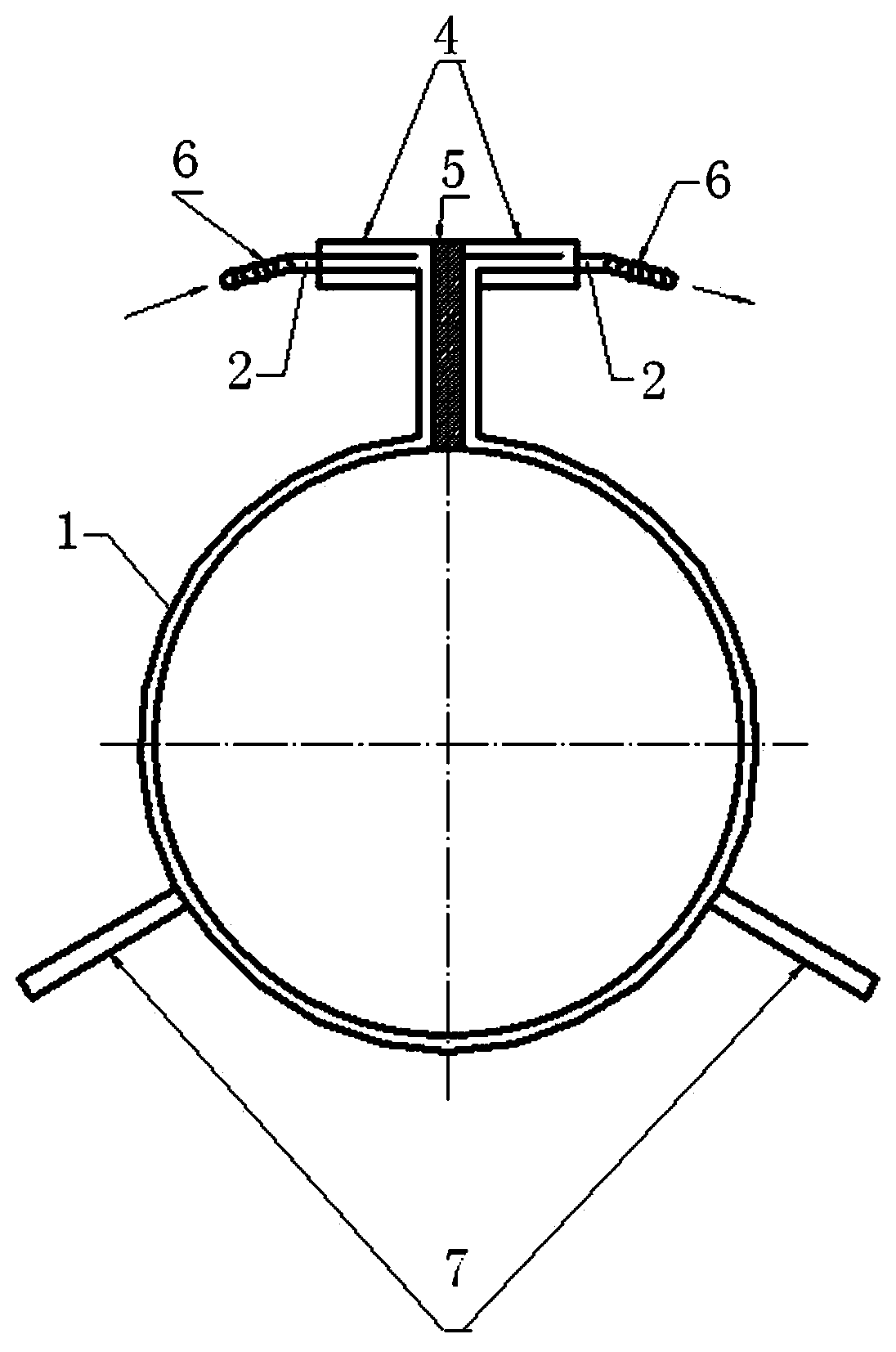

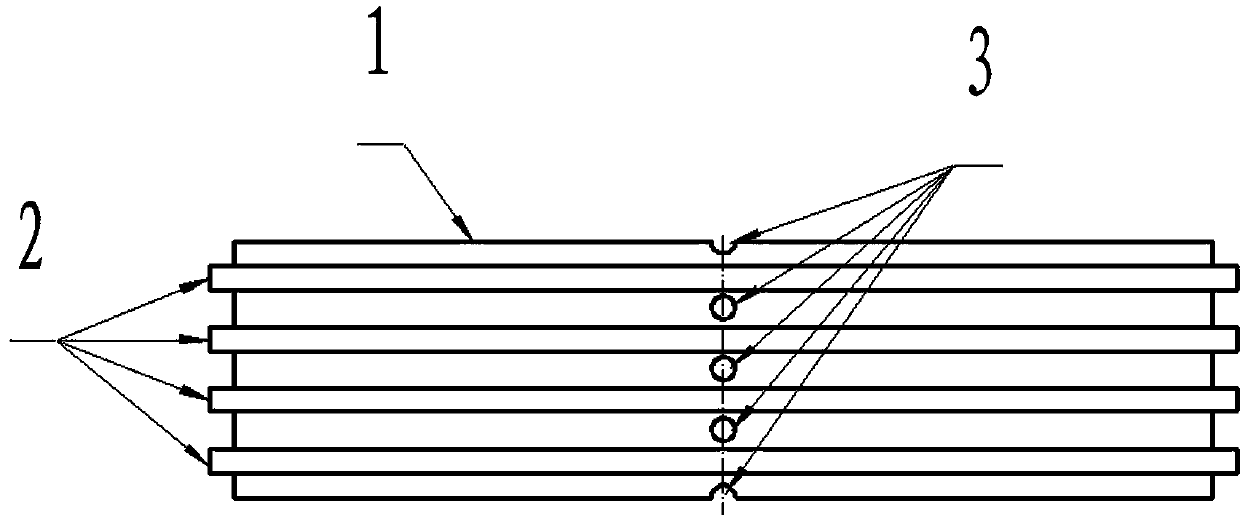

[0016] Such as Figure 1-2 Shown: an inductor for quenching large forged steel backup rolls, the inductor includes an induction coil 1 made of copper plate, the outer side of the induction coil 1 is provided with a surrounding cooling water pipe 2, and the induction coil 1 is provided with a The temperature measuring hole 3 at the gap between the cooling water pipe 2 is provided with a connecting piece 4 at both ends of the induction coil 1 for connecting the inductor to the induction transformer, and the two ports of the cooling water pipe 2 are set at the connecting piece 4 In addition, two ports of the cooling water pipe 2 are respectively provided with cooling water pipe joints 6 . In addition, an insulating block 5 is filled in the gap between the two ends of the induction coil 1 and a fixing bracket 7 is provided on the induction coil 1 .

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com