Elastic support mechanism of wind-resistant spherical support

An elastic bearing and spherical bearing technology, applied in bridge parts, bridges, buildings, etc., can solve the problems of impact, non-metallic sliding plate falling off, and non-metallic sliding plate damage of friction pair, so as to prevent the damage of friction pair. , to avoid the effect of emptying the force plane and smooth load transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

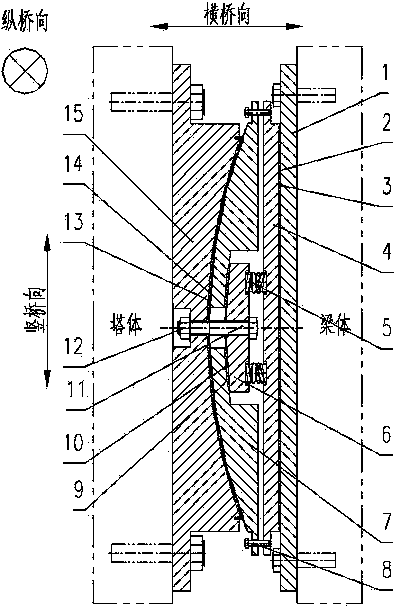

[0021] The present invention is illustrated with reference to the accompanying drawings and the given examples.

[0022] Such as figure 1As shown, an elastic support mechanism of a wind-resistant ball bearing, the elastic support mechanism has a seat plate IV (7); the seat plate IV (7) is an arc-shaped spherical surface on one side, and a plane on the other side a cylindrical steel plate; the middle part of the seat plate IV (7) has a groove; the bottom surface of the groove in the middle part of the seat plate IV (7) is an arc-shaped spherical surface and is concentric with the arc-shaped spherical surface on one side of the seat plate IV (7); The elastic support mechanism has a seat plate III (6); the seat plate III (6) is a cylindrical steel plate with an arc-shaped spherical surface on one side and a plane on the other side, and the seat plate III (6) is located on the seat plate IV ( 7) In the middle groove, one side of the arc-shaped spherical surface of the seat plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com