Horizontal well reversing clamping release method

A technology for horizontal wells and derricks, which is applied in earthwork drilling, wellbore flushing, and wellbore/well components. safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

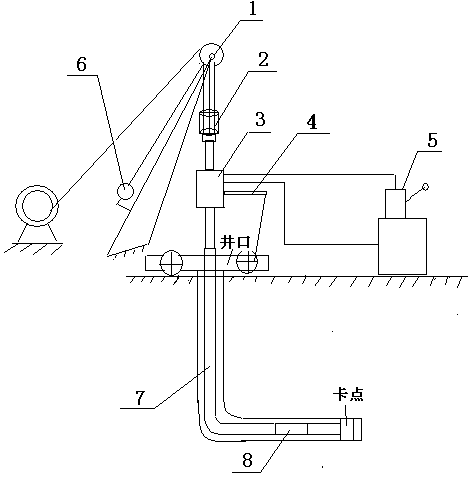

[0032] In order to overcome the deficiencies in the existing method of unblocking in the prior art in the process of unblocking horizontal wells, this embodiment provides a method such as figure 1 The shown horizontal well undercutting method includes the following steps:

[0033] 1) Connect the power swivel 3 to the swimming system 2 of the derrick crane 1, the dead rope end of the derrick crown 1 is connected to the electronic tension gauge 6, the power swivel 3 is connected to the short joint of the tubing, the power swivel 3 and the driving device 5 connections;

[0034] 2) Utilize the swimming system 2 on the derrick crown block 1 to control the lifting or lowering of the power swivel 3, so that the short joint of the tubing on the power swivel 3 is connected with the stuck tubing string 10 in the well;

[0035] 3) Fix the anti-torque balance rope 4 of the power faucet 3, lift the power faucet through the swimming system 2, and make its pulling force equal to the suspend...

Embodiment 2

[0047] On the basis of embodiment 1, the principle of the present invention's horizontal well undercutting and jamming release is as follows:

[0048] (1) The lifting force should not be too large, otherwise the amount of stuck tubing string 10 poured out would be too small;

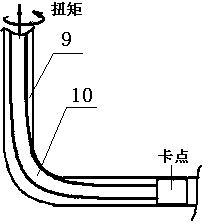

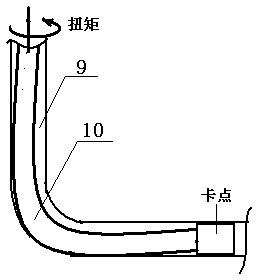

[0049] like figure 2 As shown, when the lifting force is greater than the suspended weight of the stuck pipe string 10 in the well, the stuck pipe string 10 will cling to the inner arc surface of the casing 9 at the transition between the vertical well section and the horizontal section, causing the stuck pipe The resistance of the string 10 is too high during the rotation process, and the torque at the wellhead cannot be transmitted to the position of the stuck point. As a result, the stuck pipe string 10 cannot be reversed from the build-up position during the back-off process, and the stuck pipe string 10 cannot be removed at one time. The pipe string 10 is reversed from the vicinity of the stuck po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com