Combination valve with load sensitive function and capable of controlling inlet and outlet oil ways independently

A load-sensing, combined valve technology, applied in the direction of servo motor components, fluid pressure actuators, mechanical equipment, etc., can solve the problems of low efficiency, high energy consumption of the valve control system, interchangeability and economic limitations, etc., to achieve Good interchangeability, convenient processing, considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

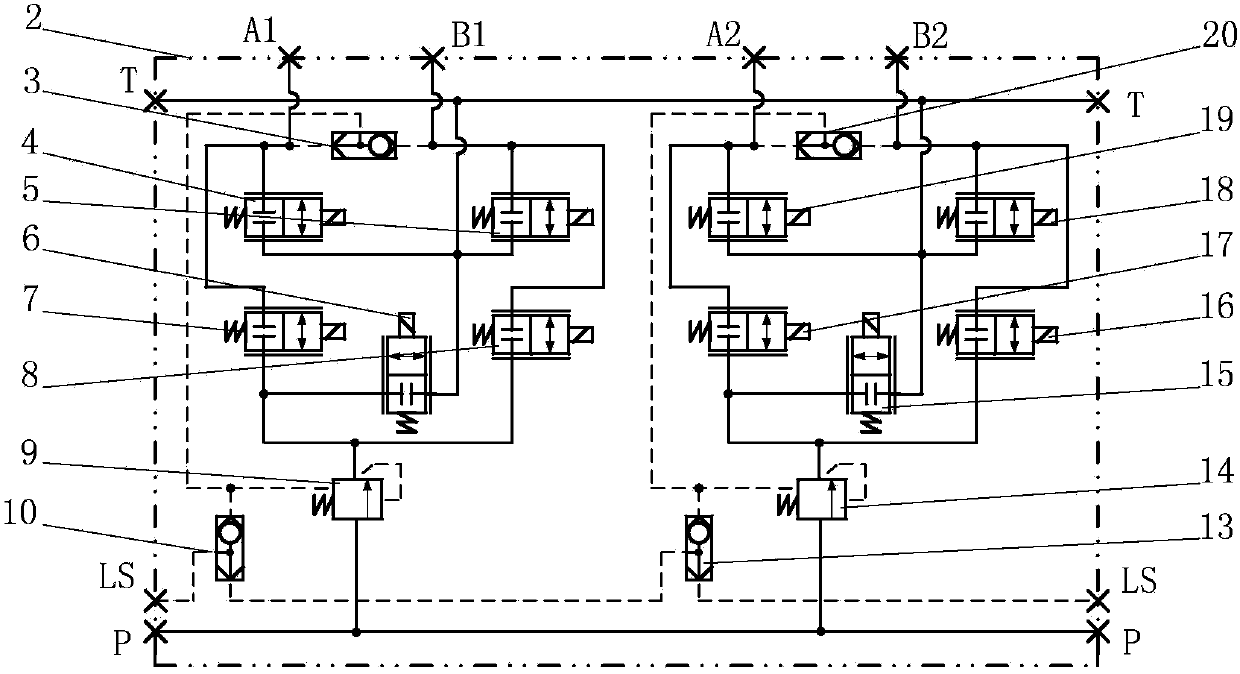

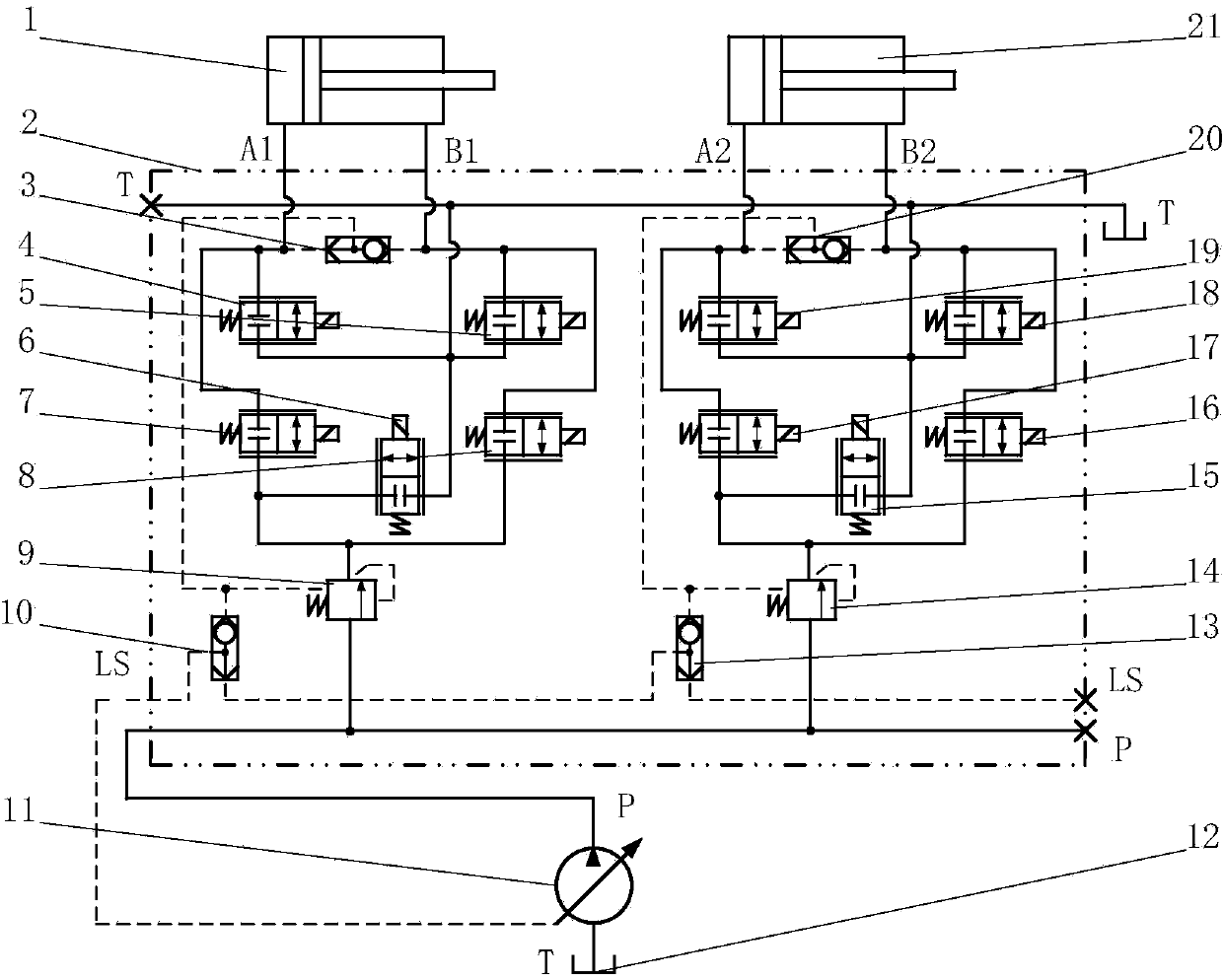

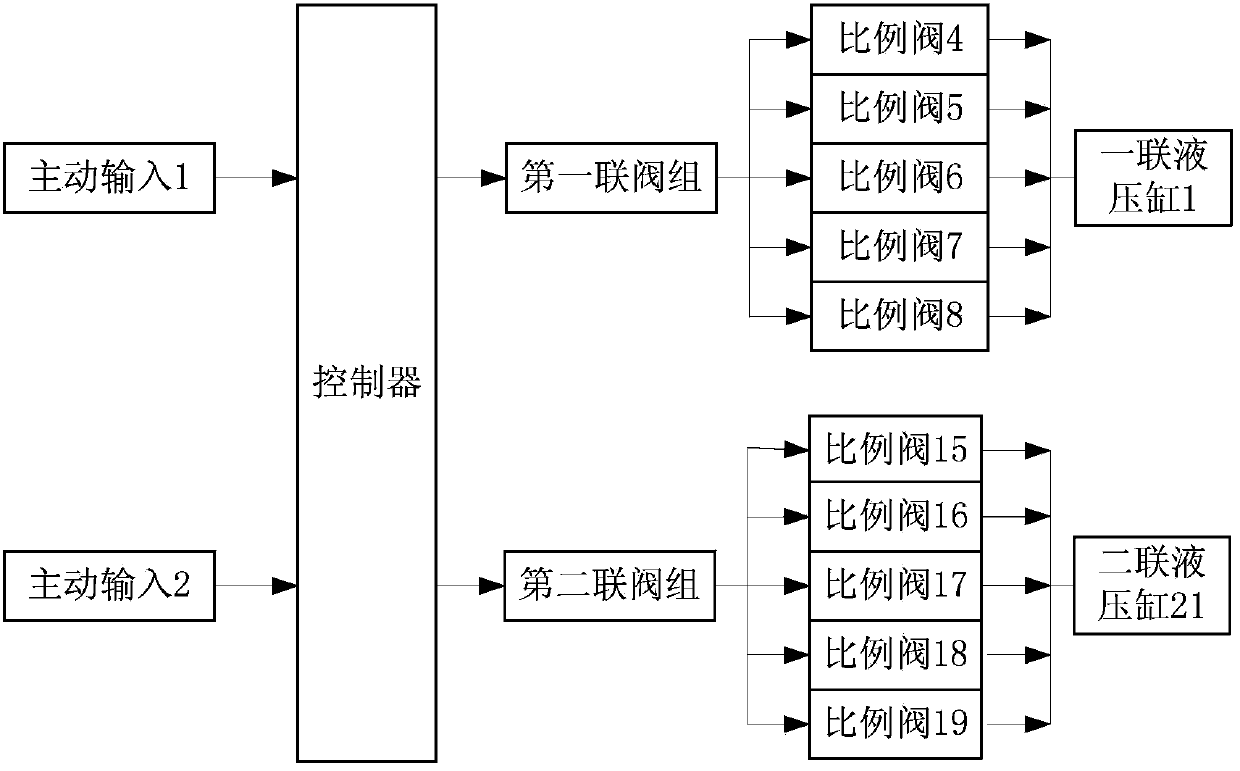

[0015] figure 1 , 2 They are respectively the hydraulic principle diagram of the combination valve hydraulic system with load-sensing function and independent control of the inlet and outlet oil circuits and the application principle diagram of the combined valve hydraulic system with load-sensing function and independent control of the inlet and outlet oil circuits according to an embodiment of the present invention. Combination valve with independent control of inlet and outlet oil circuits with load sensing function, including two valve groups, supply oil circuit P, return oil circuit T, load sensing oil circuit LS, two valve groups share a unified supply oil circuit P, oil return circuit Road T and load sensing oil circuit LS, each valve group has two output ports connected with the hydraulic actuator; the two valve groups include the first valve group and the second valve group, the first valve group The valve group and the second valve group have the same components and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com